A controllable explosion welding method for laser-induced thermal decomposition of energetic working medium

A laser-induced and explosive welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of weak material quality uniformity, poor controllability and precision, poor process controllability, etc., to overcome the laser pulse The effect of energy confinement, good stability, and efficient structural connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

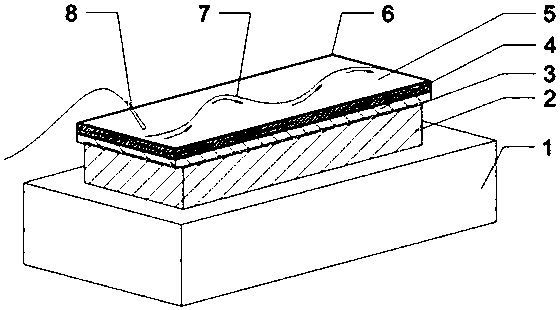

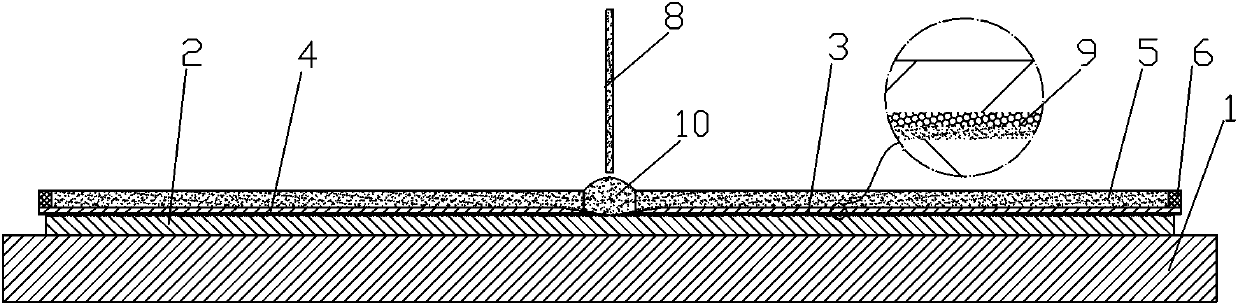

[0031] see Figure 1-2 .

[0032] The invention discloses a controllable explosive welding method for thermal decomposition of a laser-induced energetic working substance, which comprises the following steps:

[0033] a. An operating table 1 is set, and the operating table 1 is sequentially provided with a substrate 2, a sheet or film-shaped metal doubler plate 4, and an energetic working medium box 6. There is a gap between them, and the energetic working medium box 6 is a frame structure composed of four sides;

[0034] b. filling the energetic working medium box 6 with an energetic working medium 5 covering the upper surface of the doubler plate 4;

[0035] c. Apply the laser focus energy 8 to the energetic working medium, induce the rapid thermal decomposition reaction of the energetic working medium, and generate shock waves, thereby driving the doubler pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com