Device and method for detecting heat seal strength of container cover membrane

A technology of heat seal strength and detection equipment, which is applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems of inability to test the heat seal strength of products, and achieve the effect of accurate detection data, accurate readings, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

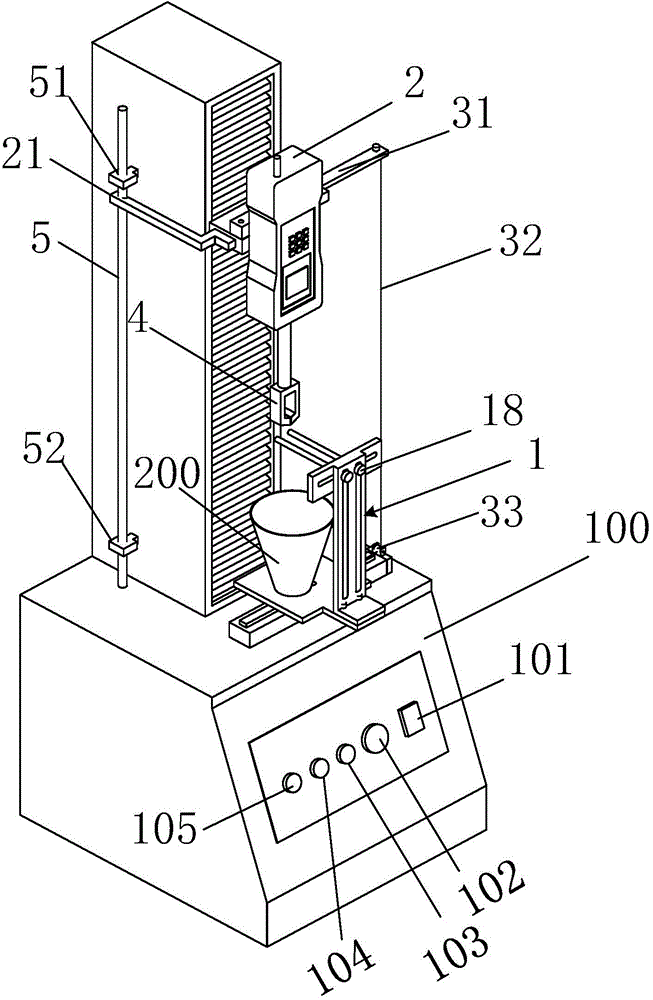

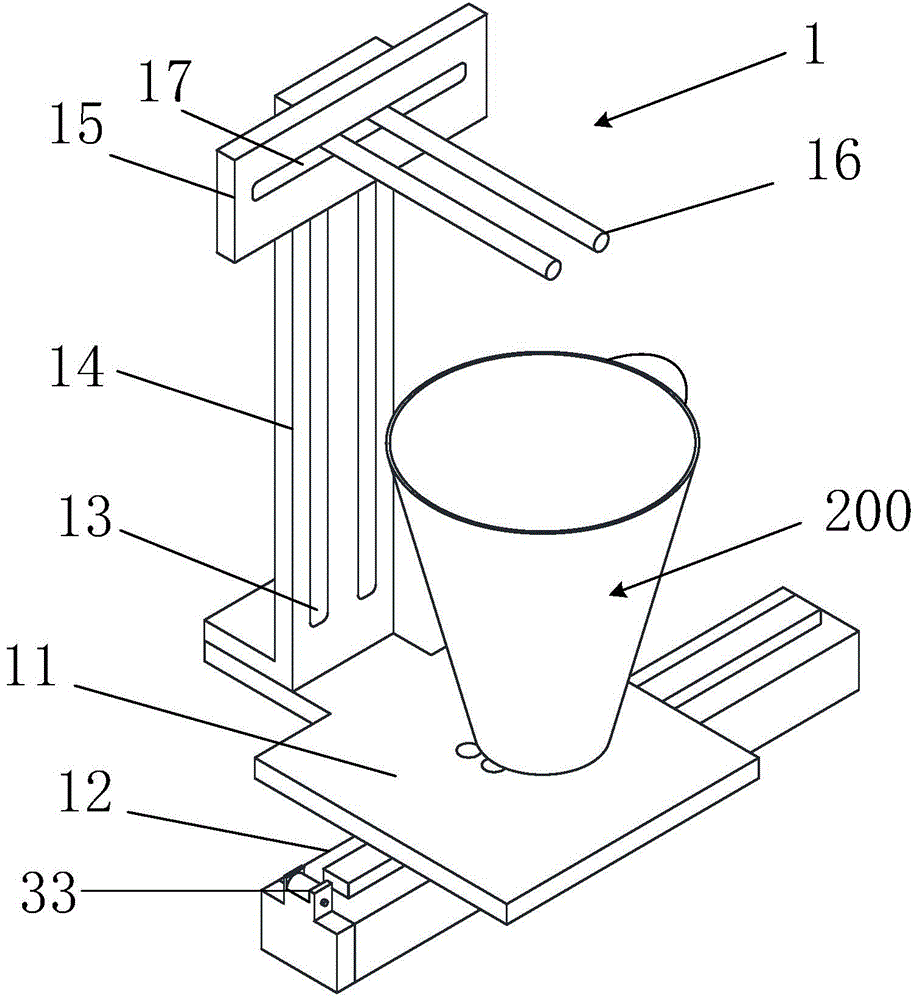

[0029] Such as Figure 1~3 As shown, the heat seal strength detection equipment of the container lid film in this embodiment includes a base 100, on which a container fixing mechanism 1 for clamping the cup body 200 to be tested is provided, and the container fixing mechanism 1 1 is provided with a digital display tensioner 2 for detecting the heat seal strength when the cover film is torn, and a clamping mechanism that can tear the cover film from the vertical direction is connected to the bottom of the digital display tensioner 2 4.

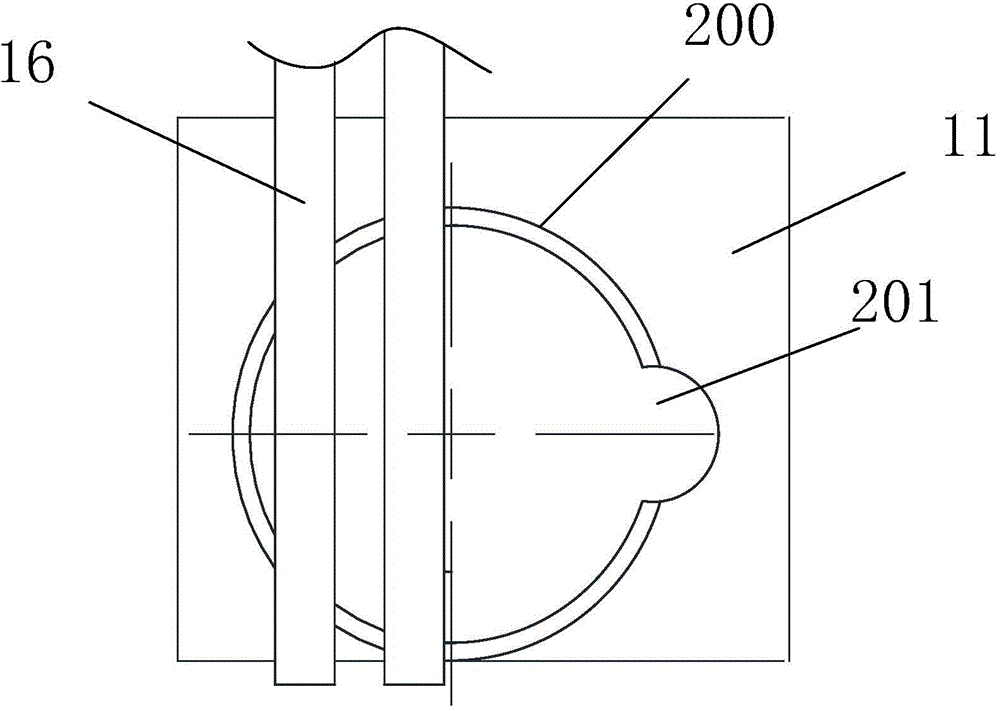

[0030] Such as figure 2 and 3 As shown, the container fixing mechanism 1 includes a bottom plate 11 for carrying the cup, and the bottom plate 11 is connected with the base 100 through a sliding mechanism. The sliding mechanism includes a slideway 12 arranged on the base 100 and a slideway matching part (not shown) arranged at the bottom of the bottom plate 11 . Also be provided with certain height support 14 on base plate 11, be provided ...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the second driving device used to drive the container fixing mechanism to move horizontally in this embodiment is a stepped constant speed motor. The rotational speed set by the stepped constant speed motor is the same as the stepped constant speed motor used to drive the digital display tensioner, so as to ensure that the cover film is always in a vertical state with the cup mouth of the cup body during the upward tearing process.

[0038] When using a stepped constant speed motor to drive the container fixing mechanism, it is sufficient to set the corresponding up button, down button, speed button, and stop button on the base. The remaining parts are the same as those in Embodiment 1, and will not be repeated here.

[0039] The method for detecting the heat seal strength of the container lid film will be described below.

[0040] Wherein the manner of locating the cup to be detected is the same as that o...

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that the sliding mechanism in this embodiment is in the form of a pulley and a directional chute. Specifically, a horizontal orientation chute is arranged on the base, and two pulleys are arranged at the bottom of the bottom plate, and the pulleys cooperate with the orientation chute to realize the horizontal movement of the container positioning mechanism. The remaining parts are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com