An X-ray fine-gauge steel wire residual stress detection and clamping device

A residual stress, clamping device technology, applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as spot size limitation, and achieve the effect of improving test accuracy, improving accuracy and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

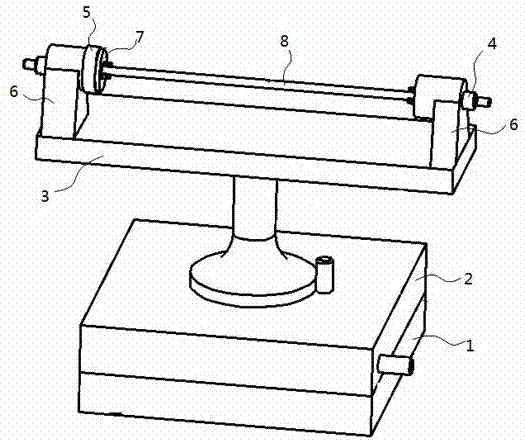

[0012] Such as figure 1 As shown, the X-ray thin-gauge steel wire residual stress detection clamping device in this embodiment includes a base 1, a movable support 2 and a crossbeam 3 arranged above the movable support 2, and the crossbeam 3 is provided with 8 clamps for steel wires. The clamping assembly, the movable support 2 can be relative to the base 1 to deflect left and right by 5° around the vertical axis and to move closer or farther away from the X-ray residual stress tester in the lateral direction. Tensioning collet 4, described tensioning collet 4 is equipped with the stress sensor 5 that is used for testing the tension force that this tensioning collet 4 acts on steel wire 8, and described tensioning collet 4 can rotate around steel wire 8 central axis .

[0013] In this embodiment, mounting bases 6 are provided at both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com