Device for testing burning and explosion characteristics of gas phase in reaction process

A technology of reaction process and measuring device, applied in the direction of material explosiveness, etc., can solve the problems of low test accuracy and operability, poor authenticity, etc., to achieve the effect of good guidance for industrial production and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

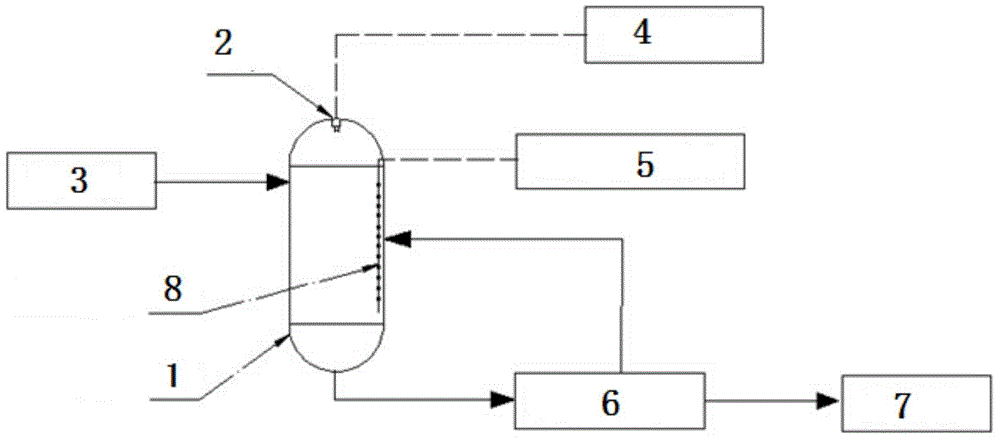

[0014] A device for measuring gas-phase combustion and explosion characteristics in the reaction process, such as figure 1 As shown, including reactor (1), ignition head (2), temperature and pressure sensor (8), feed system (3), temperature and pressure acquisition system (5), ignition control system (4) and external circulation The heat system (6), the ignition head (2) is located at the top of the reactor (1), the feed system (3) is connected to the reactor (1), and the bottom pipeline of the reactor (1) is connected to the external circulation heat extraction system (6) The inlet is connected, and the outlet of the external circulation heat extraction system (6) is divided into two paths, one path is returned to the reactor (1), and the other path is connected to the discharge system (7). The reactor (1) is axially equipped with temperature and pressure sensors (8 ), the temperature and pressure sensor (8) is connected to the temperature and pressure acquisition system (5),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com