Fabric surface specific resistance and volume specific resistance testing device

A technology of resistance testing and surface resistance, applied in the measurement of resistance/reactance/impedance, measurement device, measurement of electrical variables, etc., can solve the problems of low measurement efficiency and achieve the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in combination with specific embodiments.

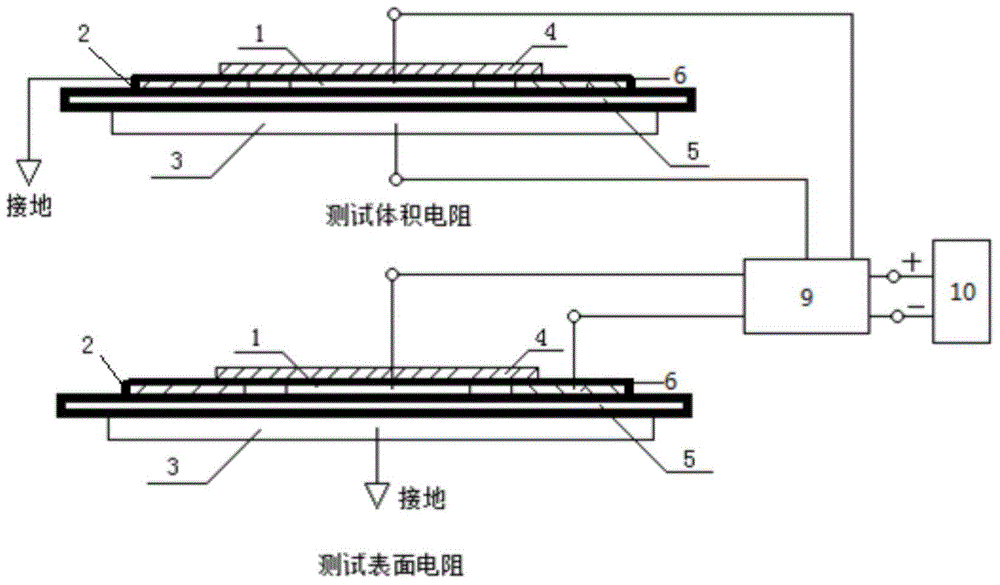

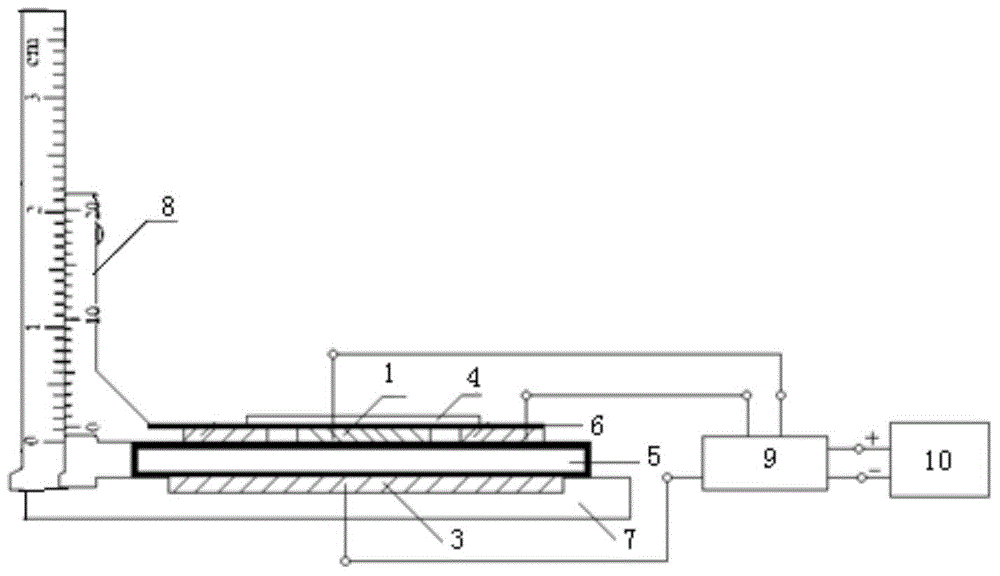

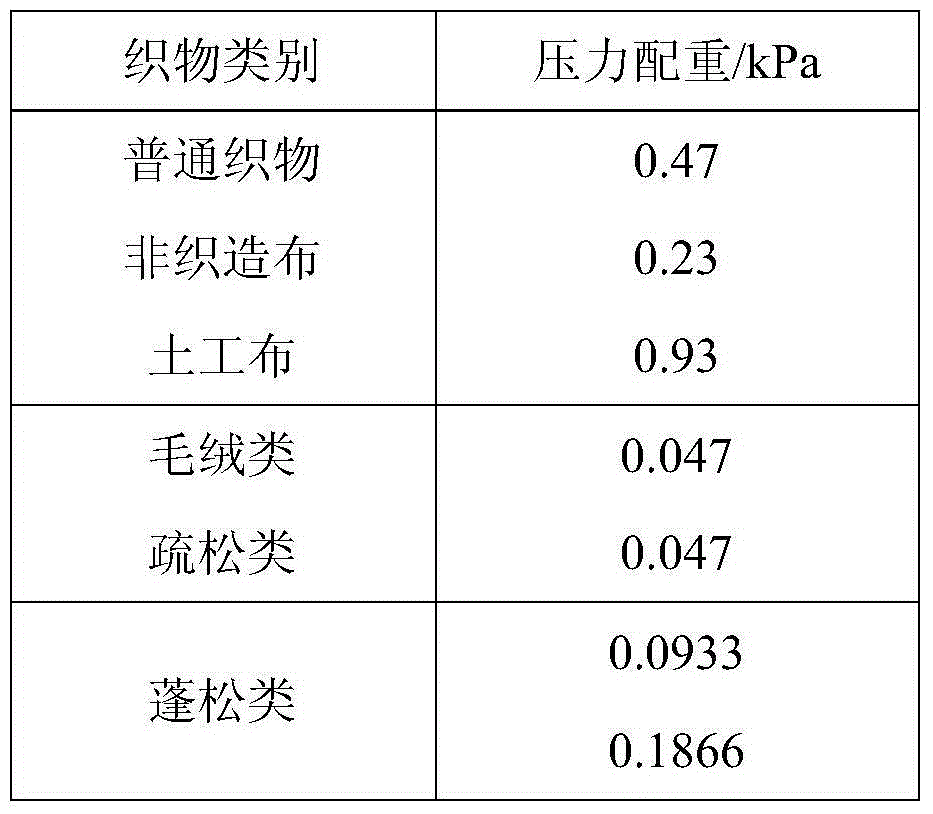

[0019] The invention is used for accurately testing the surface specific resistance and volume specific resistance of fabrics with certain geometric shapes and various specifications, as well as the thickness of the fabrics. The inventive device such as figure 1 As shown, it includes the test volume resistance system and the test surface resistance system. Both the test volume resistance system and the test surface resistance system include a stainless steel disc electrode 1 and a stainless steel ring electrode 2. The stainless steel disc electrode 1 and the stainless steel ring electrode 2 are the same layer and is in contact with the upper surface of the fabric 5, the stainless steel circular electrode 2 surrounds the circumference of the stainless steel disc electrode 1, the stainless steel disc electrode 3 is located below the fabric 5 and contacts the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com