A display panel inspection fixture

A display panel and detection fixture technology, which is applied in the direction of measuring devices, optical instrument testing, machine/structural component testing, etc., can solve the problems of small cracks on the liquid crystal panel, damage to the liquid crystal panel, and easy wear and tear of the extension part 2. Problems such as grooves, etc. To achieve long service life, reduce wear and tear, and ensure the effect of bearing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

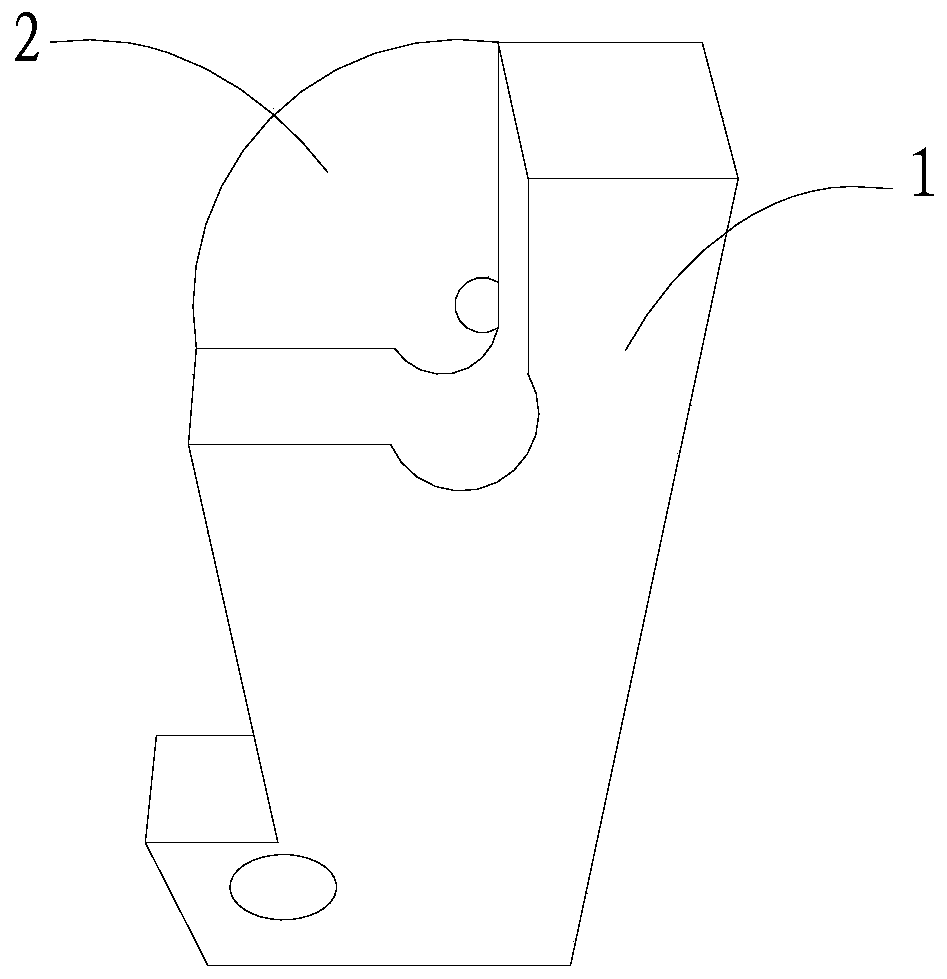

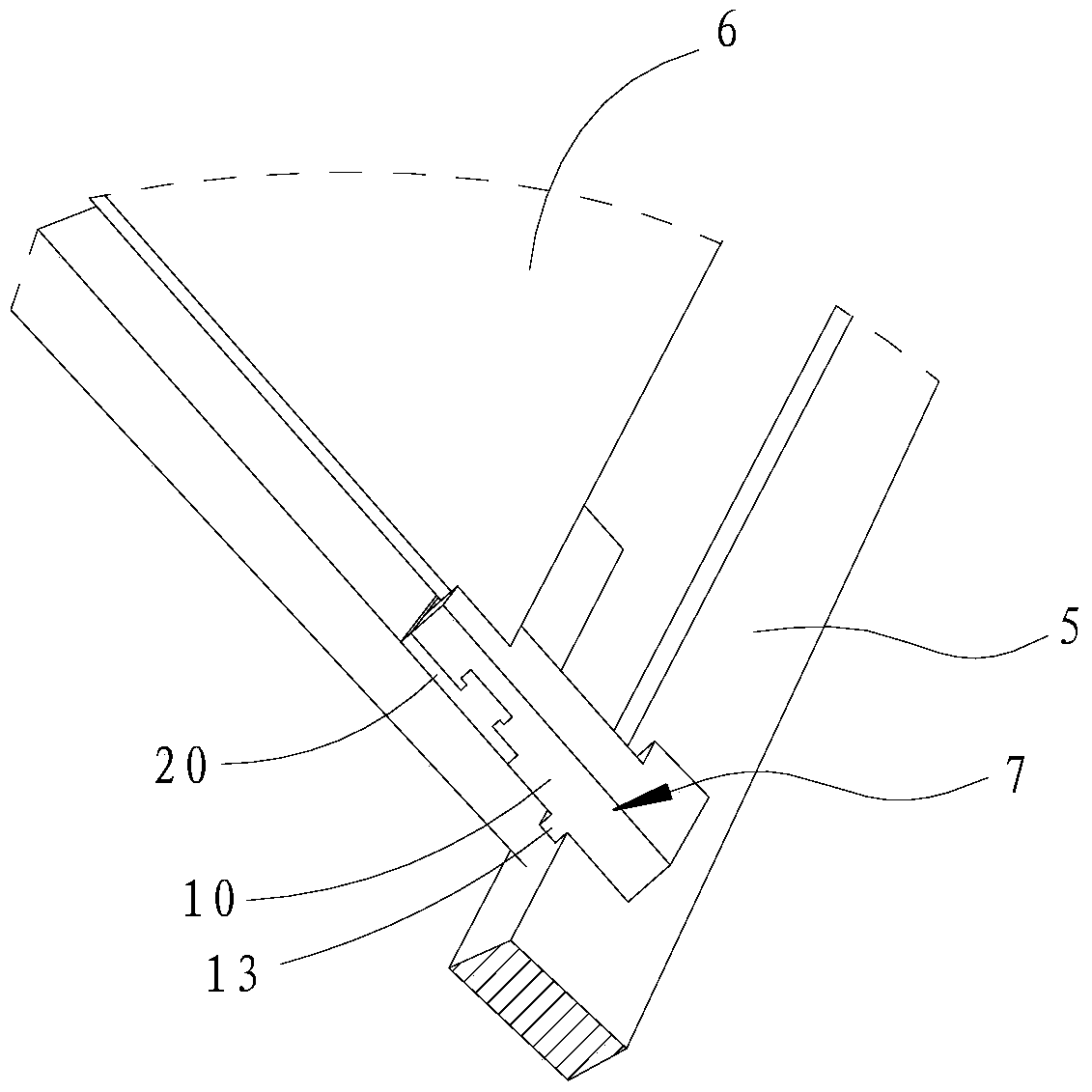

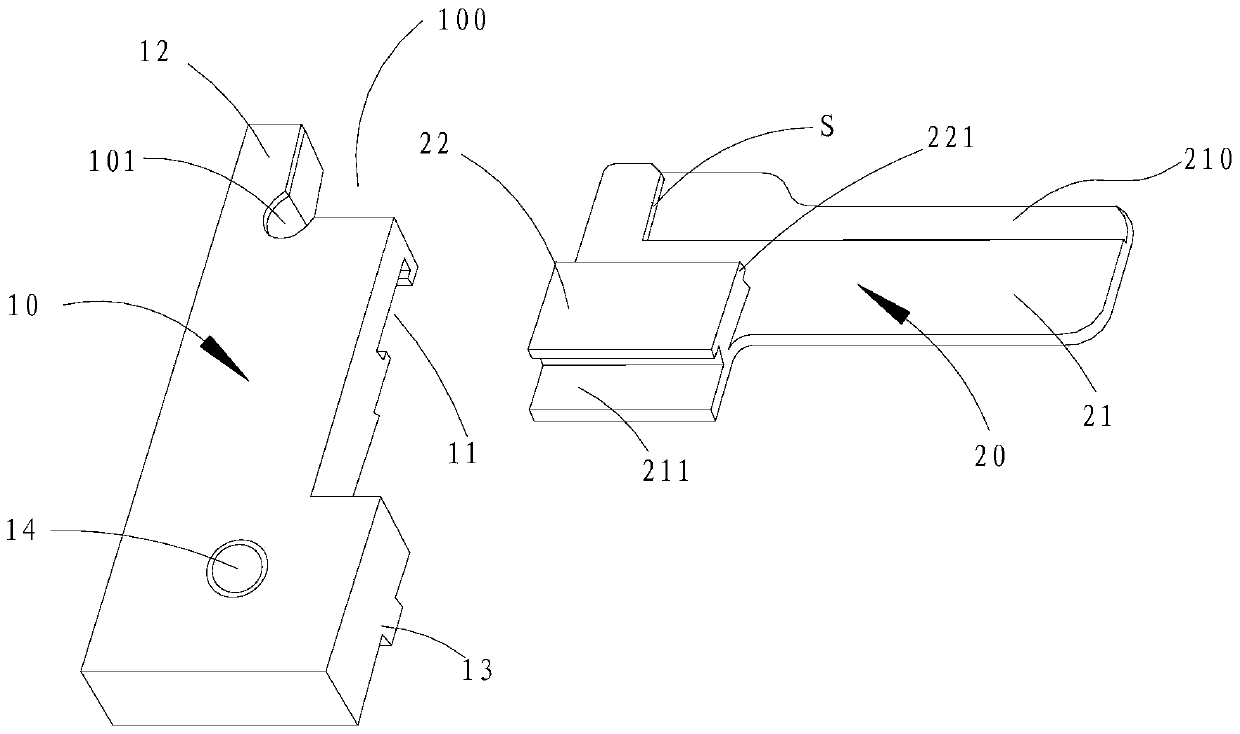

[0027] refer to figure 2 , the display panel detection jig 7 of the present invention is fixed on the detection platform 5, and is arranged at the corner of the display panel 6, and is used to make the display panel suspended and fixed on the detection platform 5 for lighting detection. The detection fixture 7 includes a briquetting block 10 and a supporting sheet 20, the briquetting block 10 is elongated and made of a composite material, and is used to extrude two adjacent side walls of the corner of the display panel 6, and the supporting sheet 20 It is detachably fixed on the detection plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com