Hollow type three-dimensional wound core and manufacturing technology thereof

A technology of three-dimensional wound iron core and manufacturing process, which is applied in the field of transformers, can solve problems such as shortage of resources, and achieve the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

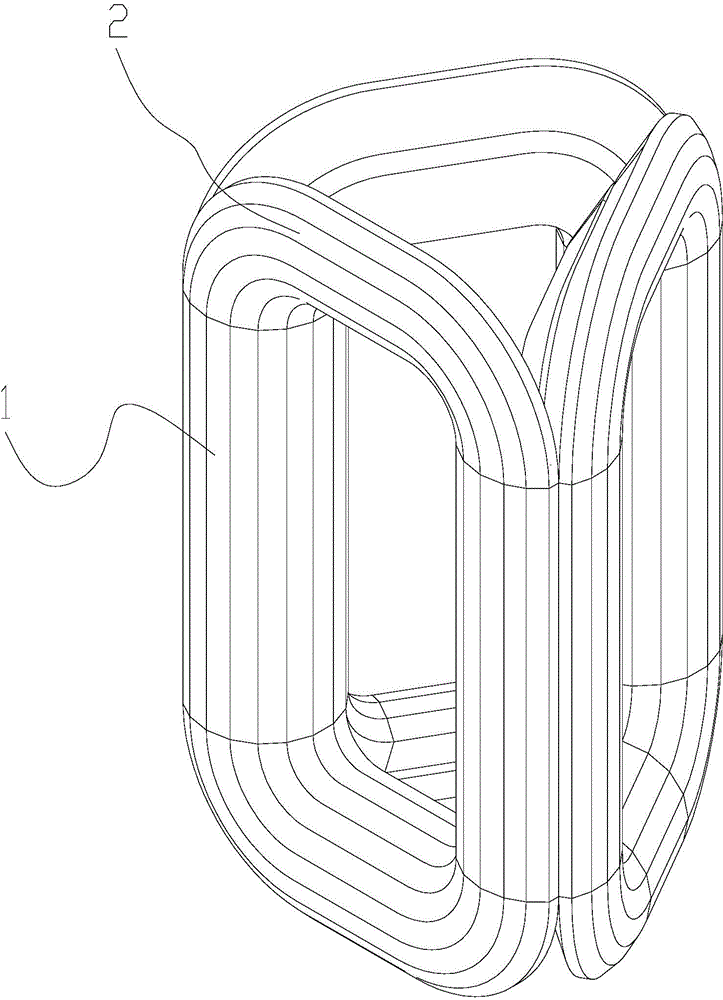

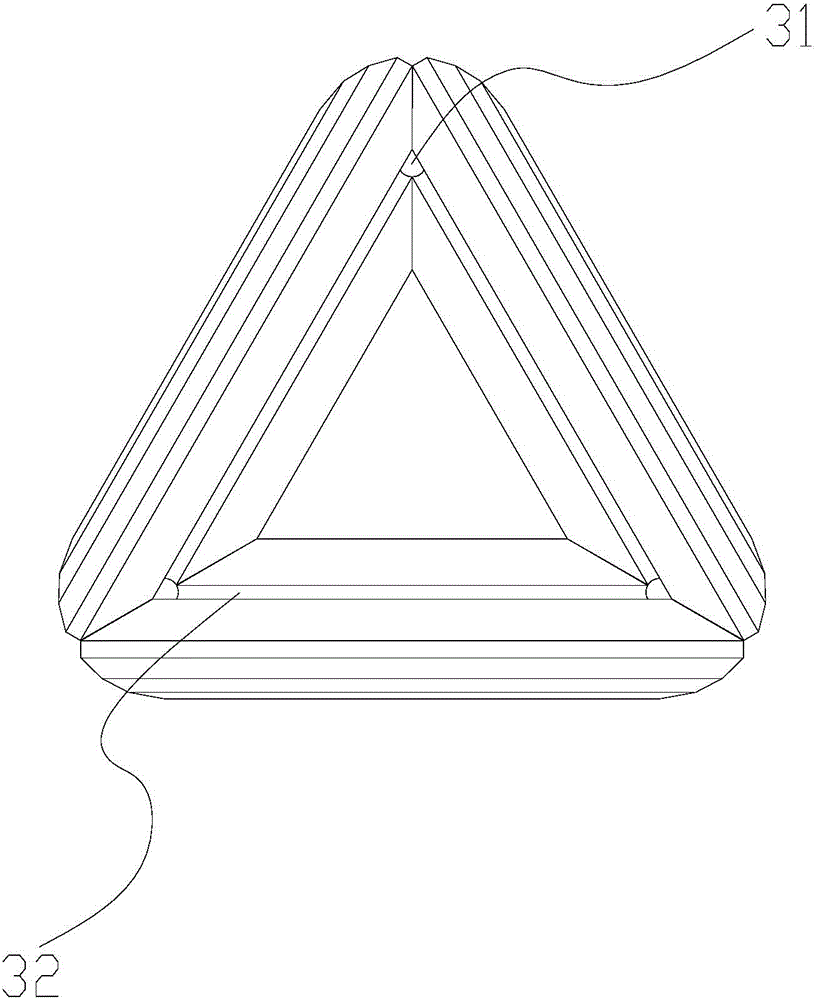

[0019] refer to Figure 1 to Figure 3 , a kind of hollow three-dimensional wound iron core of the present invention is mainly formed by combining three completely identical single-frame iron cores, and the vertical frame sides of the three single-frame iron cores are combined to form three iron core columns 1 of the wound iron core, and the horizontal frame sides Forming the iron yoke 2 of the rolled iron core, three iron core columns 1 are arranged in an equilateral triangle three-dimensionally, and a hollow groove structure 3 is arranged on the vertical frame side and the horizontal frame side of each single frame iron core.

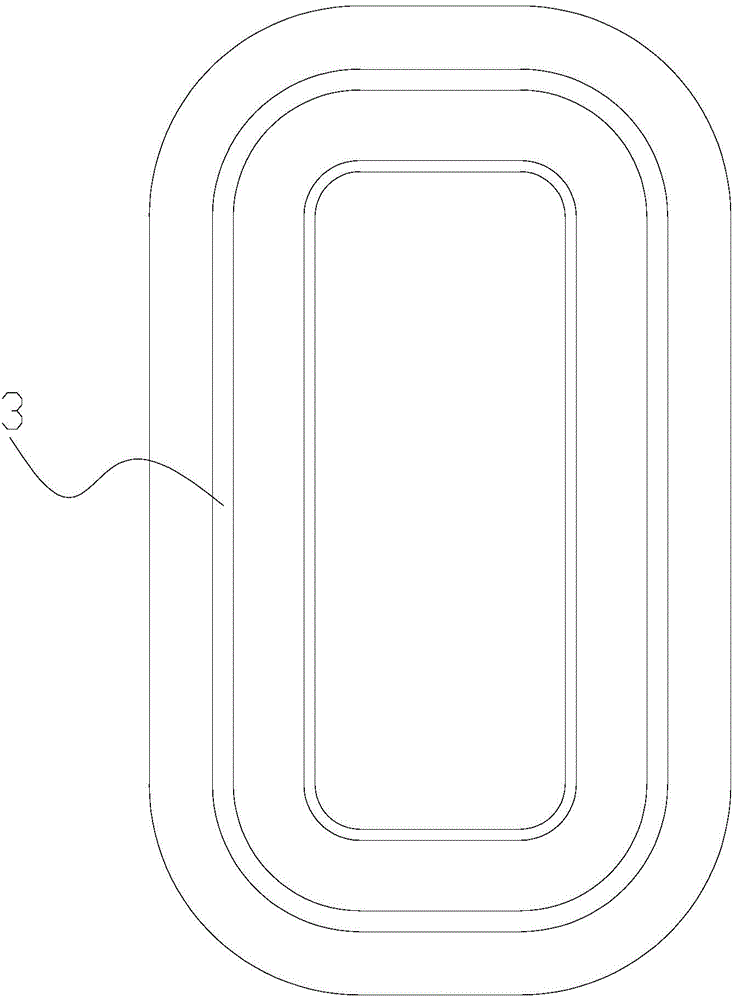

[0020] For the form of the hollow groove structure 3 on the side of the mullion and the horizontal frame, the present invention does not make specific requirements. In this embodiment, the hollow groove structure 3 on the side of the vertical frame and the horizontal frame is connected as a whole, It is in the shape of a rectangular ring.

[0021] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com