Cutting equipment for unmanned aerial vehicle shell plate

A technology for cutting equipment and shell panels, which is applied in the field of drones and can solve problems such as single functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

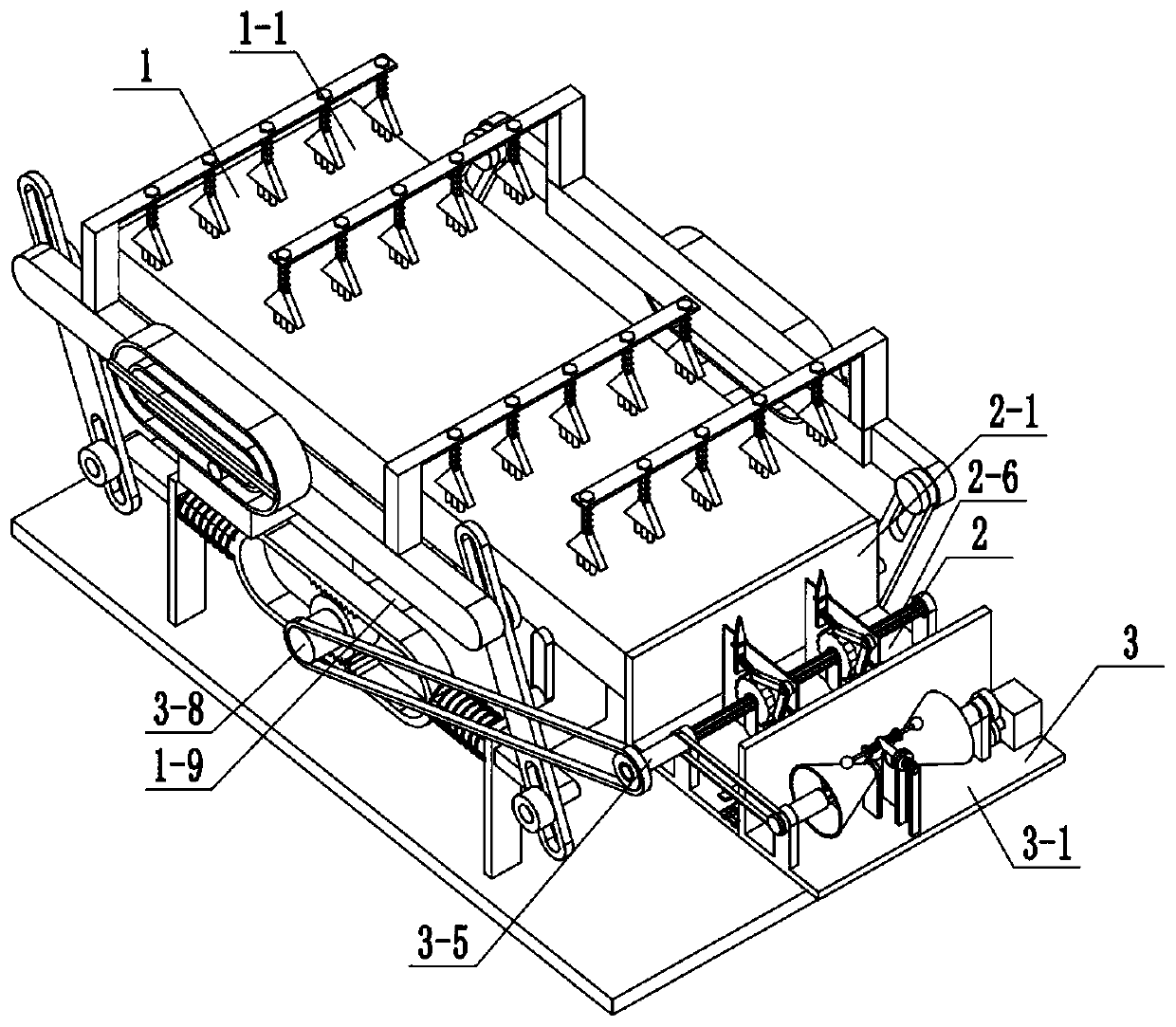

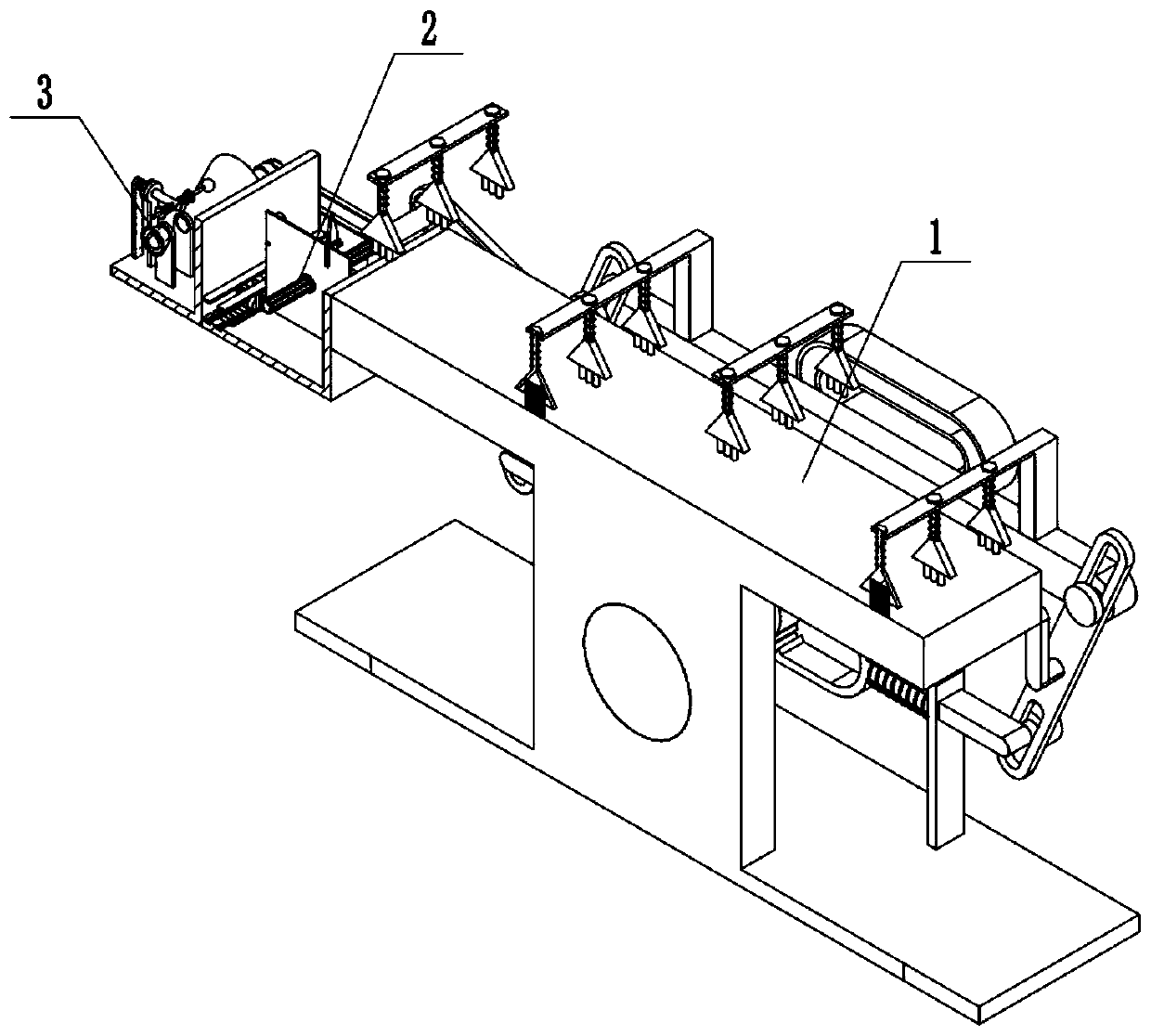

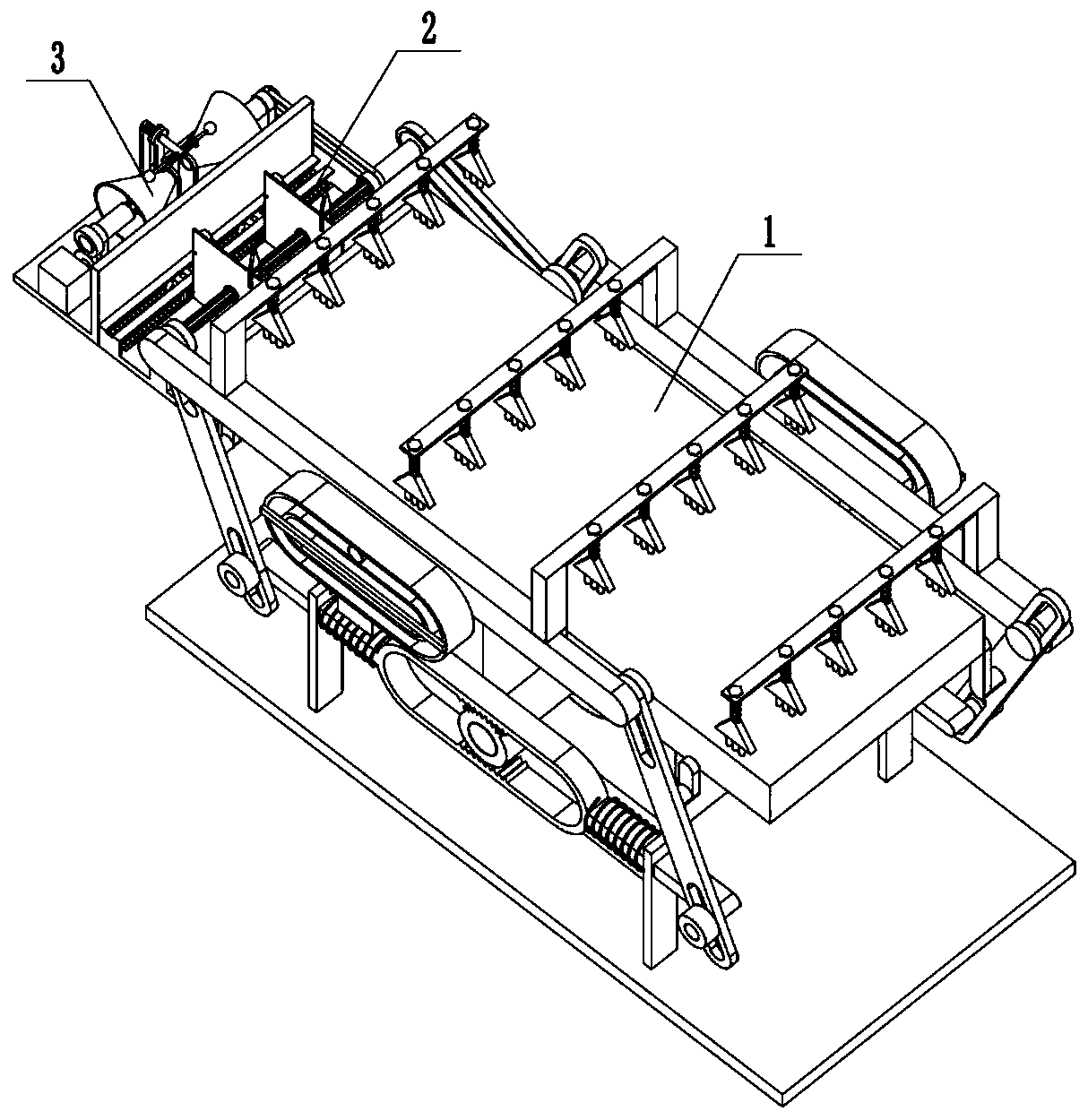

[0031] Combine below Figure 1-15 Describe this embodiment, a kind of cutting equipment of unmanned aerial vehicle shell plate, comprise stepping transportation assembly 1, cutting assembly 2, power source assembly 3, it is characterized in that: described stepping transportation assembly 1 and cutting assembly The body 2 is connected, the cutting assembly 2 is connected with the power source assembly 3, and the stepping transport assembly 1 is connected with the power source assembly 3.

specific Embodiment approach 2

[0033] Combine below Figure 1-15 This embodiment will be described. This embodiment will further explain the first embodiment. The stepping transport assembly 1 includes an upper end plate surface 1-1, a bottom plate 1-2, an auxiliary bracket one 1-3, an auxiliary bracket two 1-4, Auxiliary hinge rod 1-5, auxiliary hinge rod 2 1-6, bracket 1-7, bracket spring 1-8, auxiliary rotating rod 1-9, half gear 1 1-10, half gear 2 1-11, auxiliary cross Rod one 1-12, drive hinge rod one 1-13, transverse carriage one 1-14, drive hinge rod two 1-15, limit frame one 1-16, limit groove one 1-17, auxiliary cross bar two 1-18, driving hinge rod three 1-19, horizontal carriage two 1-20, driving hinge rod four 1-21, limit frame two 1-22, limit slot two 1-23, push rod 1-24 , push the push rod 1-25, press the terminal 1-26, the middle end push spring one 1-27, the middle end push spring two 1-28, the inner terminal 1-29, the upper end plate surface 1-1 and the bottom plate 1- 2 Fixed connection...

specific Embodiment approach 3

[0036] Combine below Figure 1-15Describe this embodiment, this embodiment will further explain the first embodiment, the cutting assembly 2 includes a cutting bottom plate 2-1, a bracket 2-2, a side wall slot 2-3, and a side wall rectangular slot 2-4 , limit bracket 2-5, drive shaft 2-6, cutting bracket 2-7, flower wheel 2-8, flower wheel bracket 2-9, matching sleeve 2-10, cutting blade 2-11, driving hinge rod 2 -12, matching roller 1 2-13, matching roller 2 2-14, middle end slider 2-15, middle end sliding column 2-16, middle end sleeve spring 2-17, matching hinge rod 2-18, matching rotor 2-19, with push spring 2-20, with rotating column 2-21, side wall sliding column 2-22, side wall sliding column push spring 2-23, rectangular boss 2-24, N-shaped frame 2-25, Roller 2-26, mid-end clamping rod 2-27, mid-end push spring 2-28, bracket 1 2-2 is fixedly connected with cutting base plate 2-1, side wall slot 2-3, side wall rectangular slot 2- 4 Set on the cutting base plate 2-1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com