Novel LED chip mounting head applied to LED chip mounter

A technology of LED placement machine and placement head, which is applied in the direction of assembling printed circuits with electrical components, electrical components, printed circuit manufacturing, etc., can solve the problems of complex adjustment process, etc., and achieve the effects of convenient adjustment, reasonable structure and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described below in conjunction with specific embodiments.

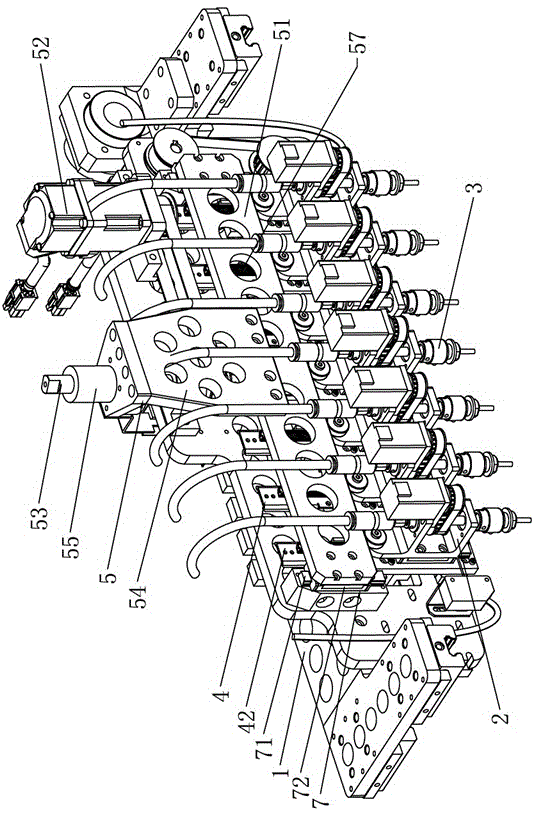

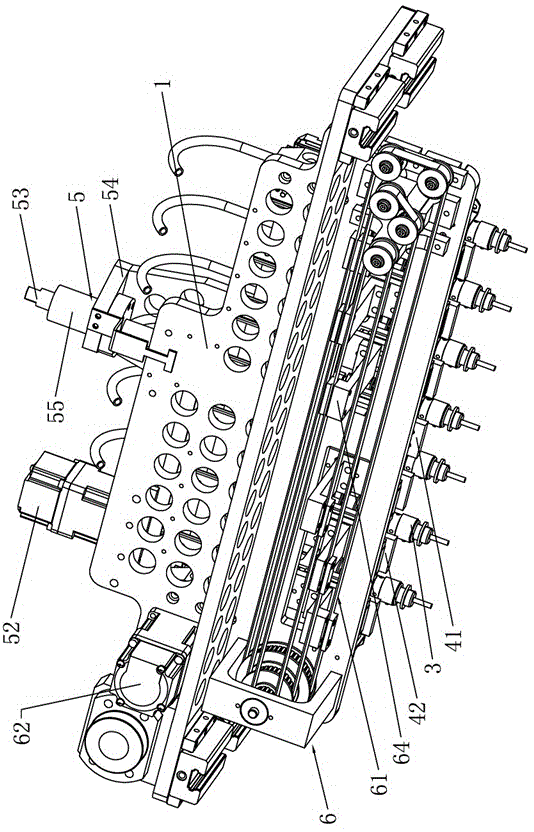

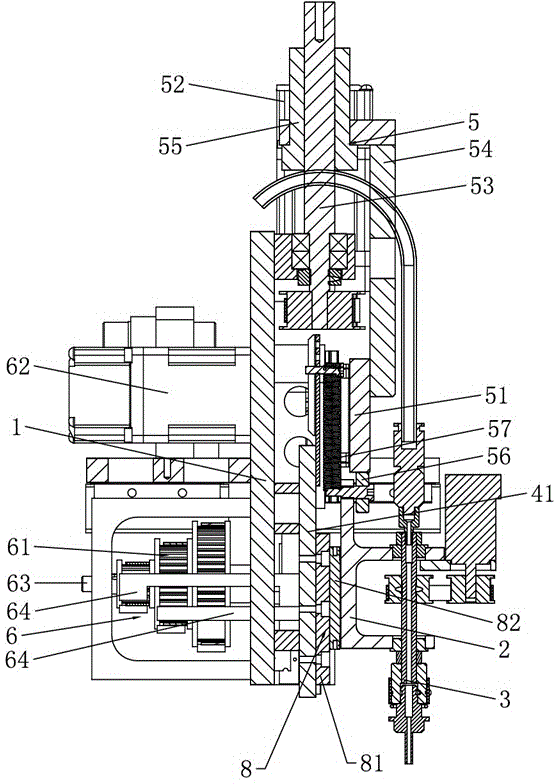

[0038] Such as Figure 1 to Figure 4 As shown, a new type of lamp chip mounting head applied to LED placement machines includes a mounting head movable mounting frame 1. Arranged suction head mounting base 2, each suction head mounting base 2 is respectively equipped with a lamp particle suction head 3, and the mounting head movable mounting frame 1 is respectively equipped with a vertically arranged mounting head corresponding to each suction head mounting base 2 The vertical plate 4 is installed, and each suction head mounting seat 2 can be installed on the mounting head mounting vertical plate 4 relatively up and down, and the mounting head movable mounting frame 1 is equipped with a lift that drives each suction head mounting seat 2 to move up and down synchronously. The driving mechanism 5 and the lifting driving mechanism 5 are respectively drivingly connected with each suct...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap