Method for operating a drive unit for a hybrid vehicle

A technology of hybrid electric vehicles and drive units, which is applied to the layout of multiple different prime movers of hybrid electric vehicles and general power plants, motor vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

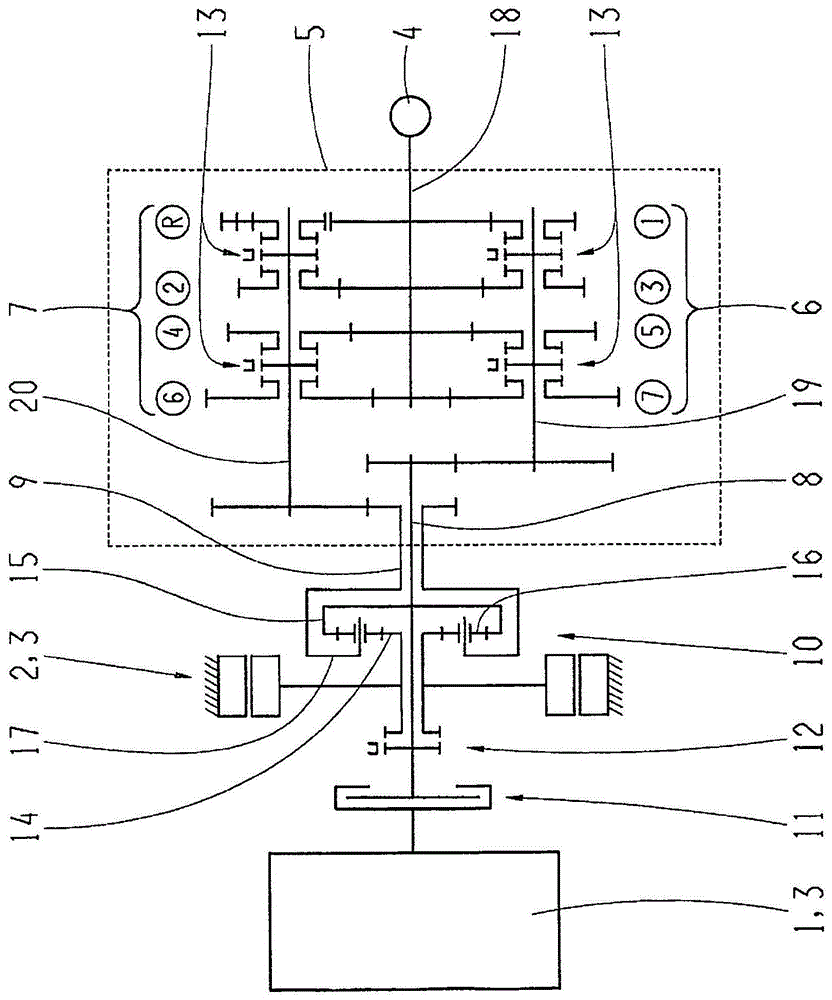

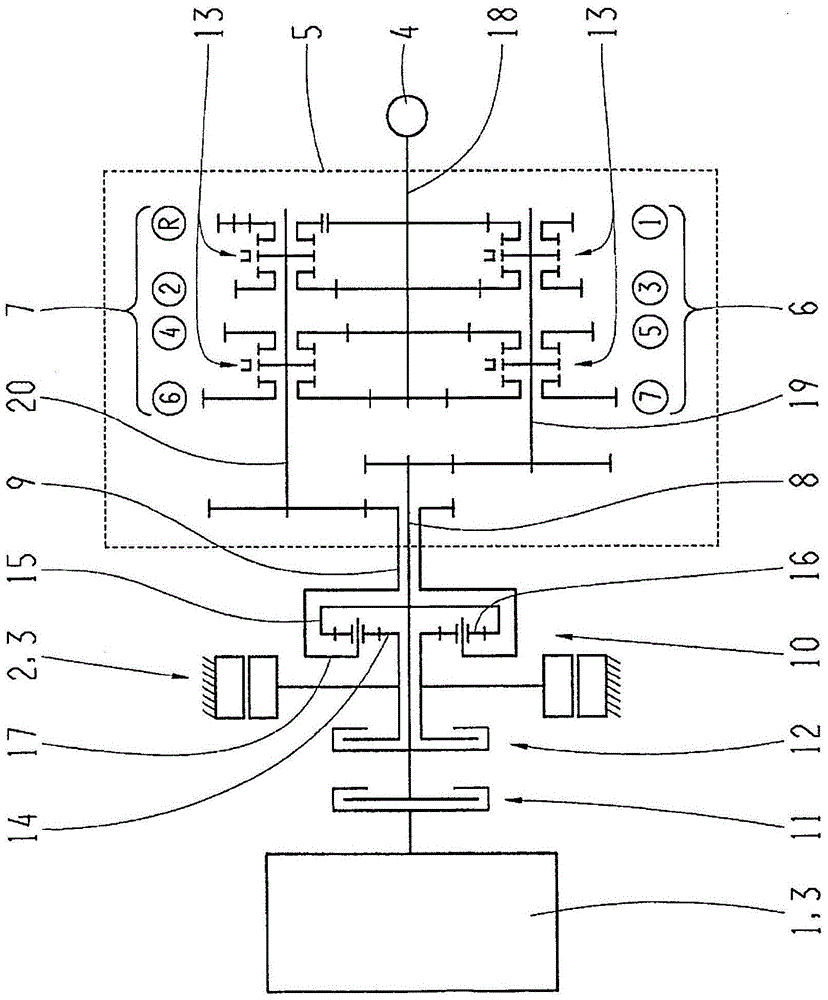

[0022] figure 1 A schematic diagram showing a drive unit for a hybrid vehicle. figure 1 The drive unit comprises a drive unit 3 formed by an internal combustion engine 1 and an electric machine 2 , wherein a transmission 5 is connected between the drive unit 3 and an output 4 . The transmission 5 comprises two sub-transmissions 6 and 7, which are so to speak parallel to each other, wherein, in the embodiment shown, the first sub-transmission 6 provides the forward gears "1", "3", "5" and "7", while the second sub-transmission 7 provides forward gears "2", "4", "6" and reverse gear "R". sub-transmissions 6 and 7 in the figure 1 The gear sets shown in and the shown assignment of the gears to the two subtransmissions are exemplary properties.

[0023] To provide forward and reverse gears, the subtransmissions 6 and 7 of the transmission 5 include form-fitting shifting elements 13 , also called shifting elements. The construction and arrangement of the subtransmissions 6 and 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com