Seamless stent and manufacturing method thereof

A manufacturing method and seamless technology, applied in the direction of the bracket, can solve the problems of uneven distribution of radial force and axial force at the free end of the bracket, affecting the service life of the bracket, affecting the aesthetics of the bracket, etc., and achieving radial force and axial force Uniform force distribution, convenient laser welding, and excellent aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

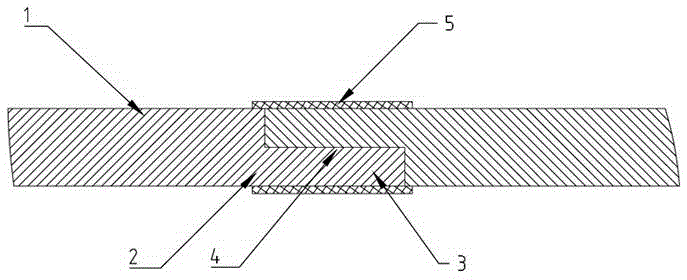

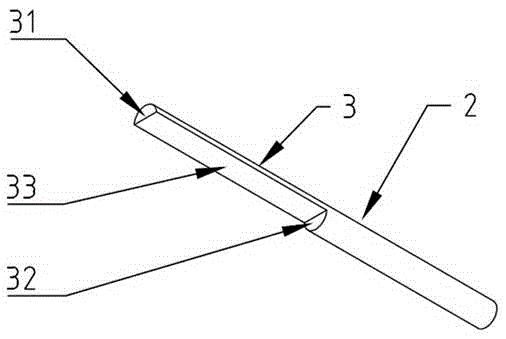

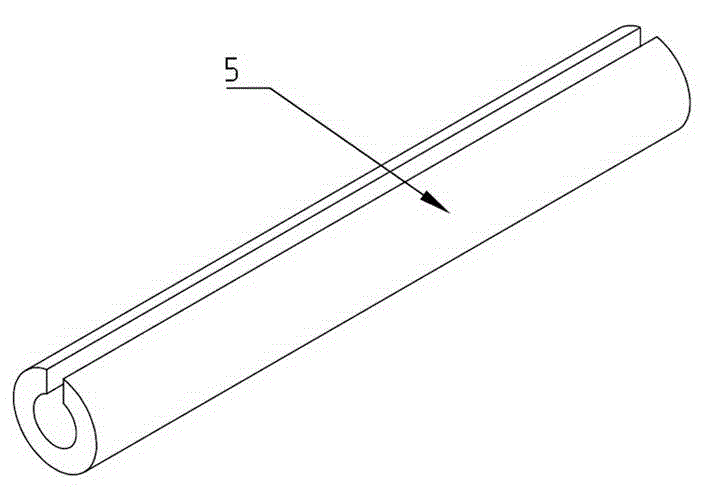

[0029] The present invention provides a seamless stent for intervening inside blood vessels, such as Figure 1 to Figure 3 As shown, the seamless support is made of at least one braided wire 1, and the braided wire 1 has an even number of free ends 2, and the free ends are the joints of the braided wires, and each braided wire has two free ends, namely the composition The plural braided wires of the seamless support have an even number of free ends, and the free ends 2 of the braided wires 1 are butted in pairs, and the butt joints are the joints mentioned below. The bracket wound by the braided wires 1 has a cylindrical structure. The free ends 2 of the wire 1 each have a cutting part 3, and the cutting parts 3 of the two opposite free ends 2 are seamlessly spliced into a splicing part 4 whose diameter is the same as that of the braided wire 1, and the splicing part 4 is covered with a connecting pipe 5 , the connecting pipe is a C-Clip pipe with an axial opening, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com