Manufacturing device and method of a bearing cap core

A technology for making devices and bearing caps, which is applied to cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of long completion cycle of finished cores, failure to meet quality requirements, and complex manufacturing processes, and achieve strong market promotion value. The effect of reducing production costs and simplifying the core making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

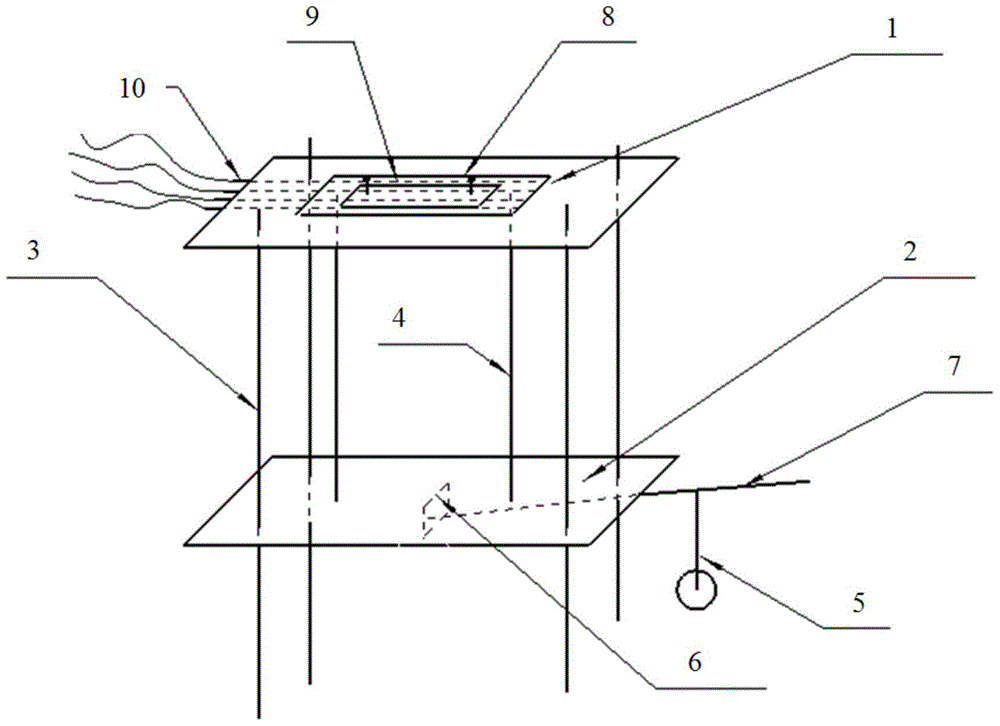

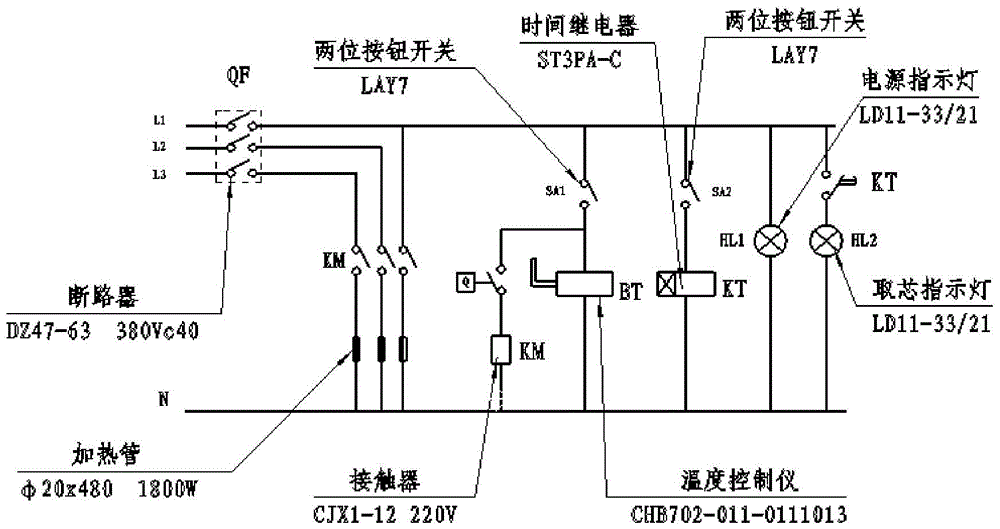

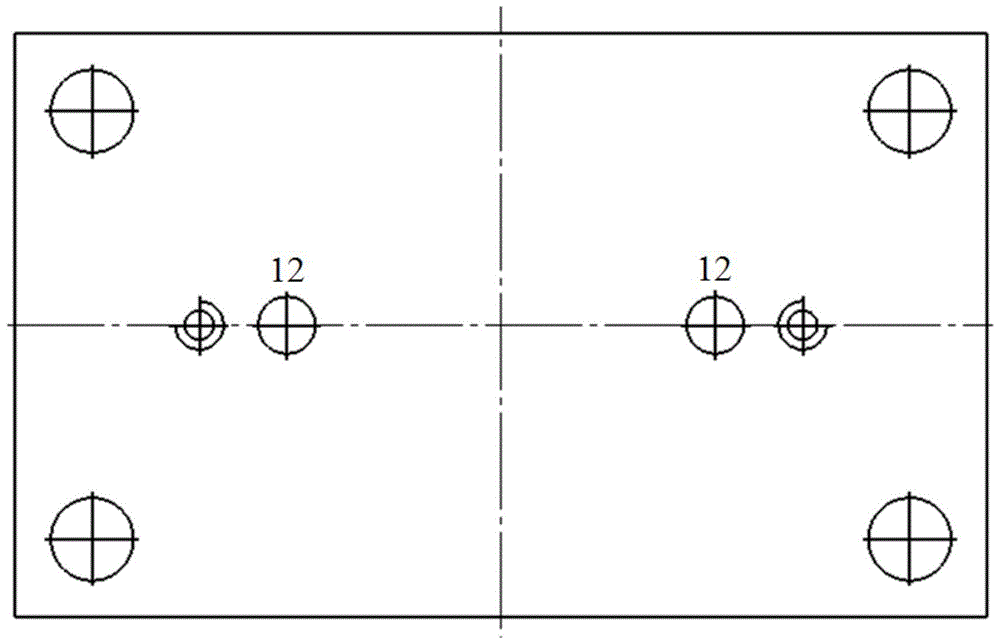

[0038] as attached figure 1 As shown, the bearing cover core manufacturing device of the present invention includes a core plate 1, a guide plate 2, a guide rod 3, a core rod 4, a support 5, a jacking seat 6, a lever 7, a core box 8, a cover board 9 and electrical control unit 10. There are preferably four guide rods 3, and the guide plate 2 is as attached image 3 As shown, it is preferably a rectangular plate, and a through hole is provided at the four corners of the plate, and the guide rod 3 passes through the through hole, so that the guide plate 2 can move up and down along the guide rod 3, and through the guide rod The moving direction of the guide plate is accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com