Three-dimensional printing device and three-dimensional printing method

A technology of 3D printing and equipment, applied in metal processing equipment, additive manufacturing, 3D object support structure, etc., can solve the problems of complex structure and high equipment cost, and achieve the effect of simple 3D printing, simplified structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

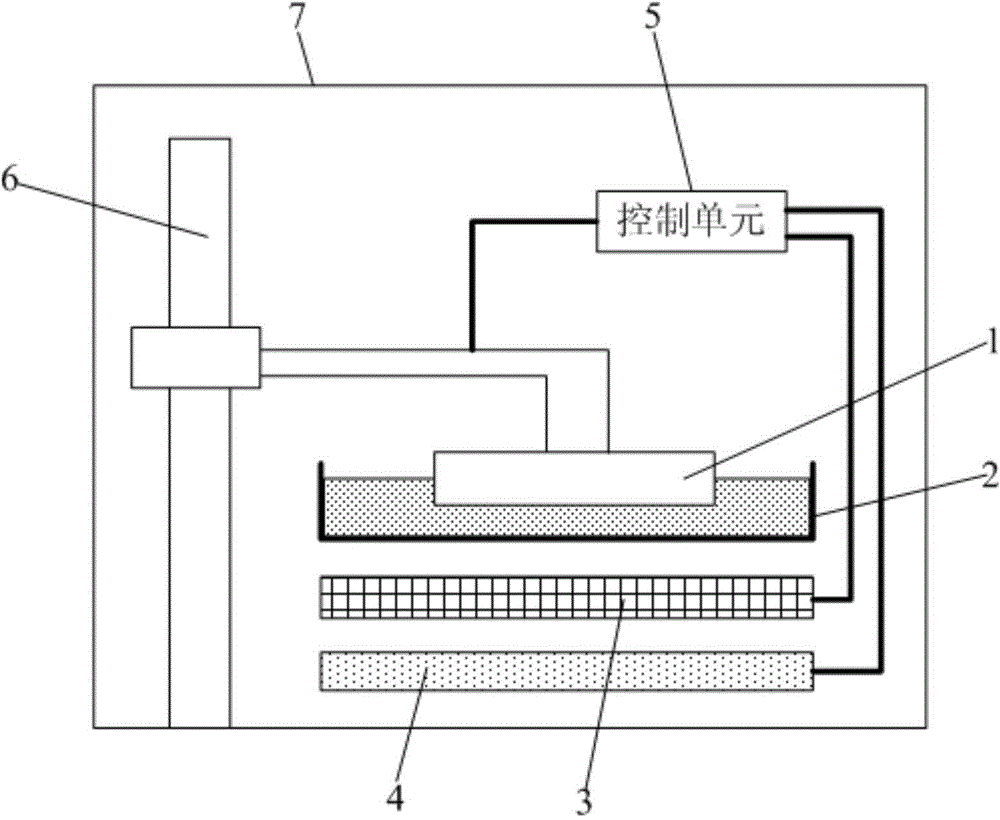

[0040] This embodiment provides a three-dimensional printing device, such as figure 2 As shown, it includes a printing table 1 and a printing tank 2. The printing tank 2 is used to accommodate materials for forming three-dimensional products. The printing table 1 is placed in the printing tank 2 to carry the three-dimensional products formed after exposure. It also includes a switch layer 3, The exposure light source 4 and the control unit 5, the switch layer 3 are set corresponding to the groove bottom of the printing tank 2; The exposure light passes or does not pass, so that the material in the printing tank 2 is exposed to form an exposure pattern.

[0041]By setting the switch layer 3, the exposure light source 4 and the control unit 5, the three-dimensional printing device can realize the exposure of the material in the printing tank 2 through a simpler structure and principle, so that the three-dimensional printing of the three-dimensional printing device is simpler an...

Embodiment 2

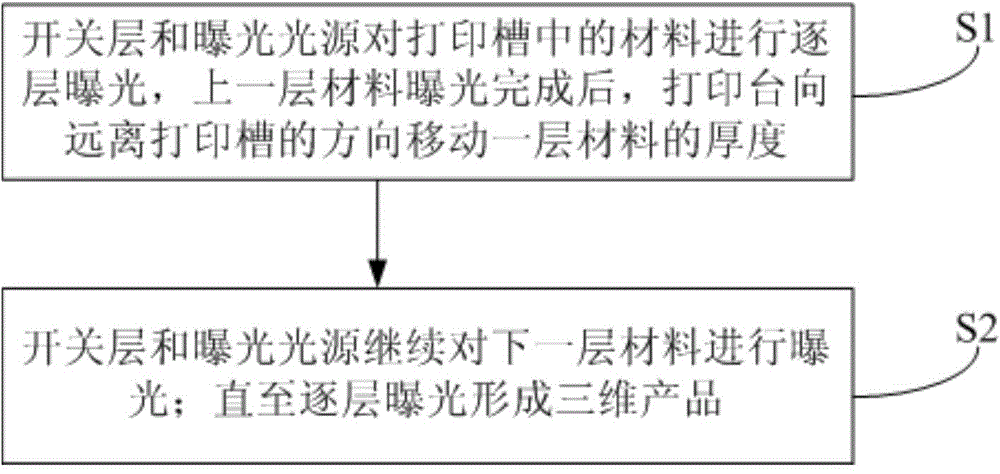

[0060] This embodiment provides a three-dimensional printing device. The difference from Embodiment 1 is that the control unit is used to control the switch element to be turned on or off frame by frame, so that the material is exposed layer by layer to form an exposure pattern. That is, the switching elements are controlled by frame-by-frame scanning to form the exposure pattern of each layer of material.

[0061] In this embodiment, the control unit is used to control the exposure light source to be turned off after the exposure of the previous layer of material is completed; and to control the exposure light source to be turned on after the printing platform moves the thickness of one layer of material to expose the next layer of material . Such setting can not only shorten the exposure time of each layer of material relatively, and prevent false exposure during the time period from the end of the exposure of the previous layer of material to the start of the exposure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com