Fixing system of cargo transporting carriage and cargo transporting carriage

A technology for fixing systems and carriages, applied in cargo support/fastening parts, transportation and packaging, railway car body parts, etc., to reduce costs and improve transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

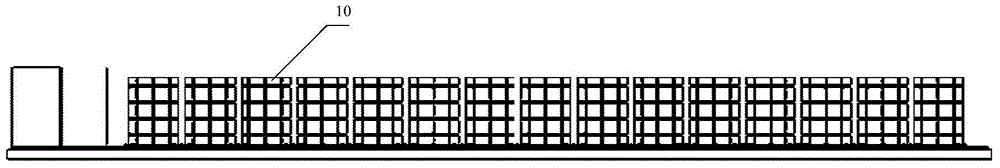

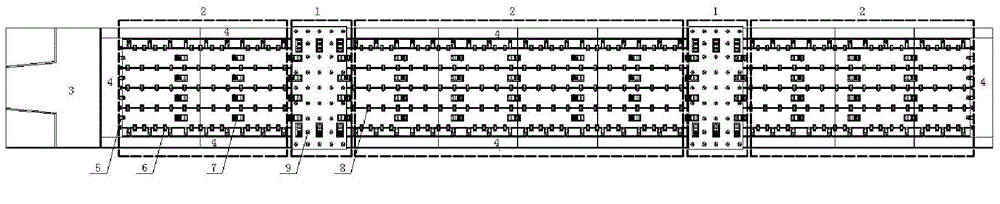

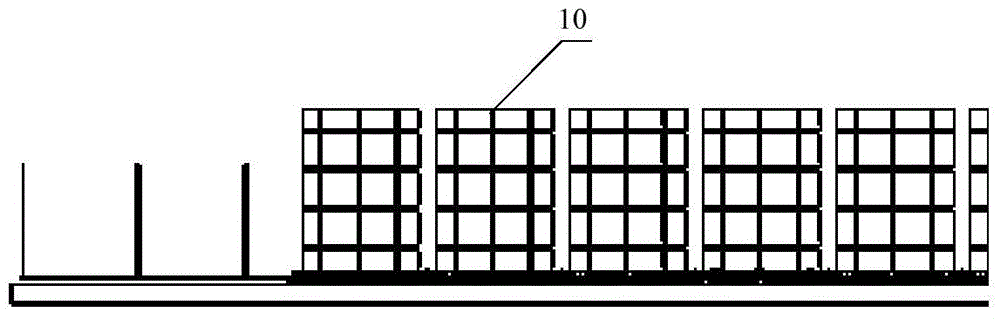

Image

Examples

Embodiment Construction

[0043] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0044] In order to solve the problems existing in the prior art, the present invention provides a fixing system for a freight car, the fixing system includes a doorway area floor and a non-doorway area floor in the freight car, and the doorway area floor is set There are a plurality of first rolling mechanisms for allowing lateral and longitudinal movement of cargo on the floor of the doorway area along the cargo compartment, and a plurality of overturning limiting mechanisms. It can be switched between a limiting state and a non-limiting state, and is used to allow the goods to pass over it in the non-limiting state, and limit the goods in the limiting state; the non-doorway A plurality of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com