A centrifugal compressor thrust bearing

A centrifugal compressor, thrust bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of complicated structure design and lubricating oil system, no self-adaptive ability, inconvenient installation and disassembly, etc. Production and maintenance, simple and compact structure, stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the solution.

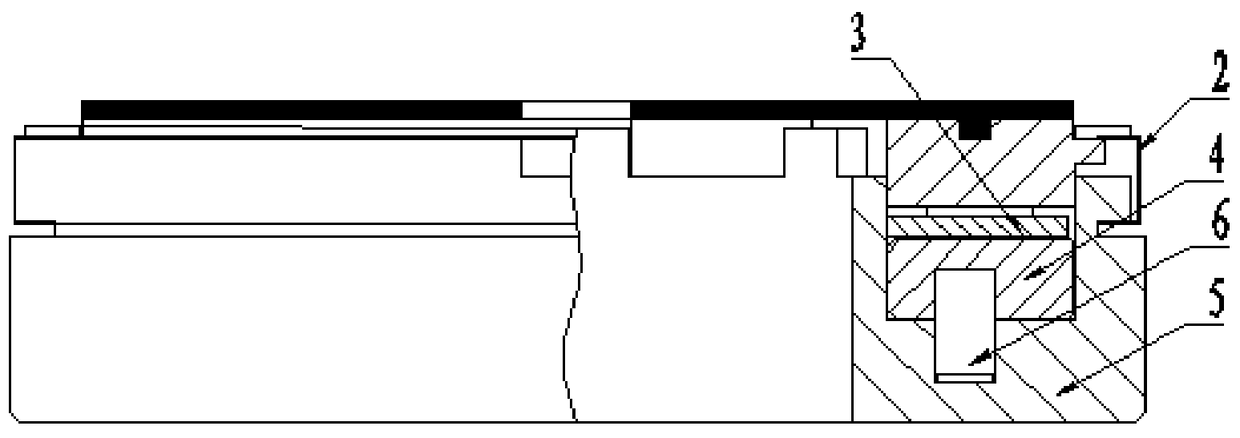

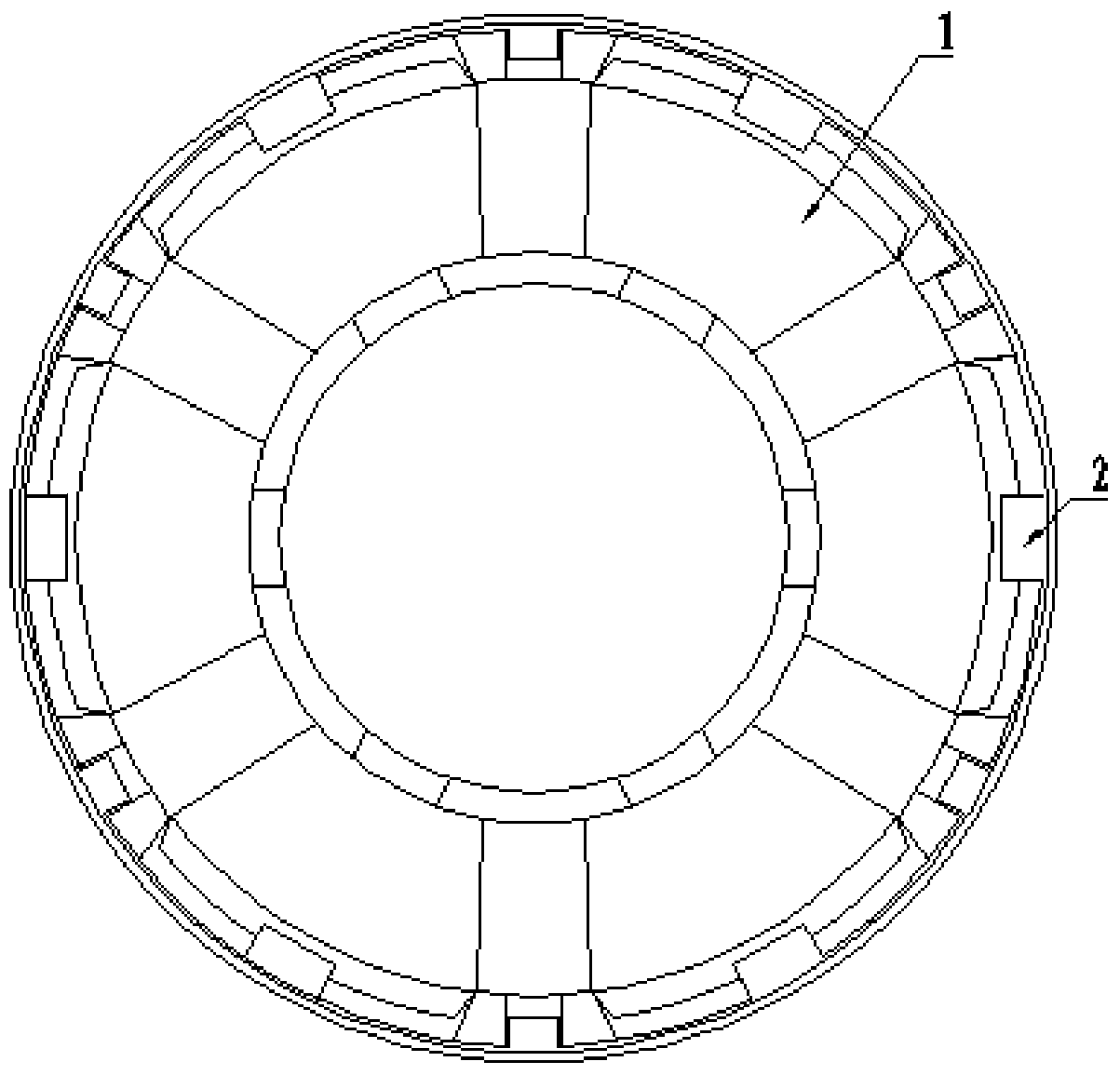

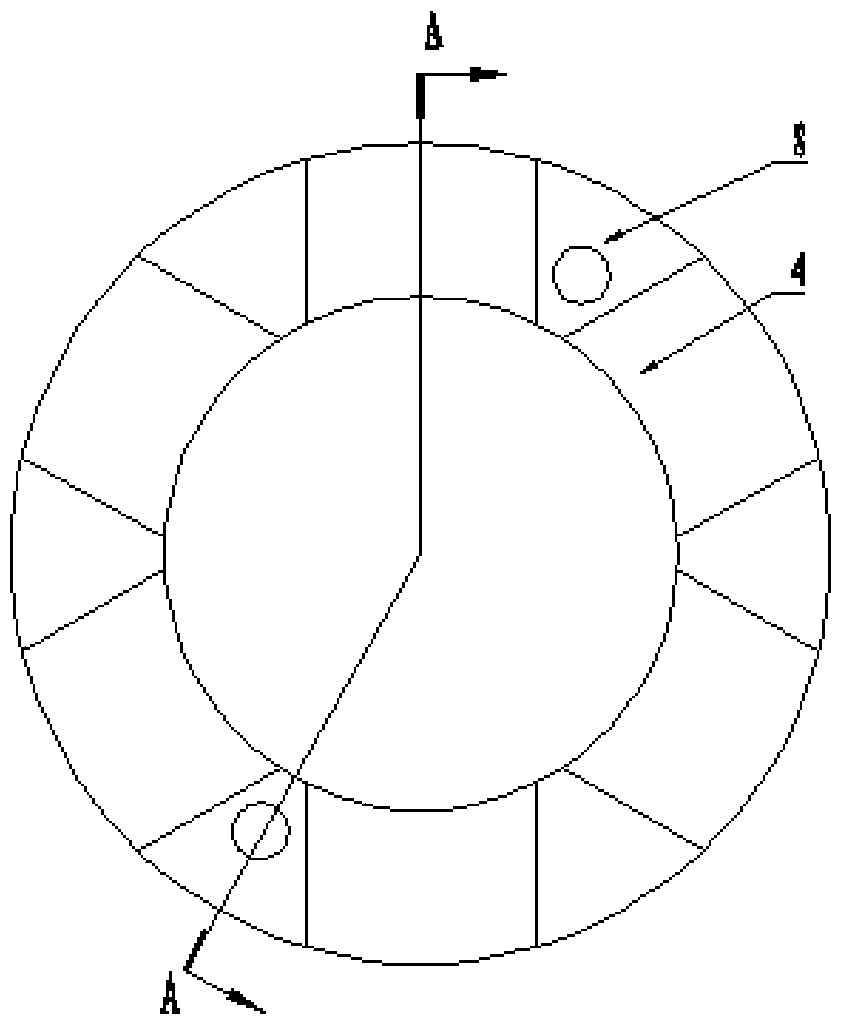

[0020] as attached figure 1 , attached figure 2 As shown, the centrifugal compressor thrust bearing includes a thrust block 1, a clamp 2, an elastic pad 3, an adjusting gasket 4, a bearing housing 5, and a positioning pin 6. The adjusting gasket 4 is connected to the bearing housing 5, and the elastic force The pad 3 is connected with the adjusting gasket 4 and the thrust block 1 respectively, and a positioning pin 6 is also connected between the adjusting gasket 4 and the bearing housing 5. function, the clamp 2 is respectively connected with the bearing housing 5 and the thrust block 1; more specifically, the thrust surface of the thrust block 1 is poured with a babbitt alloy layer with a thickness of 1 mm to 2 mm, and the babbitt alloy layer The thickness is 1.5mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com