Light distribution lens and system for uniform light direct-down LED backlighting and a TV

A backlighting and direct-lighting technology, which is applied in the field of backlighting to achieve the effects of increasing intensity, improving uniformity of light and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

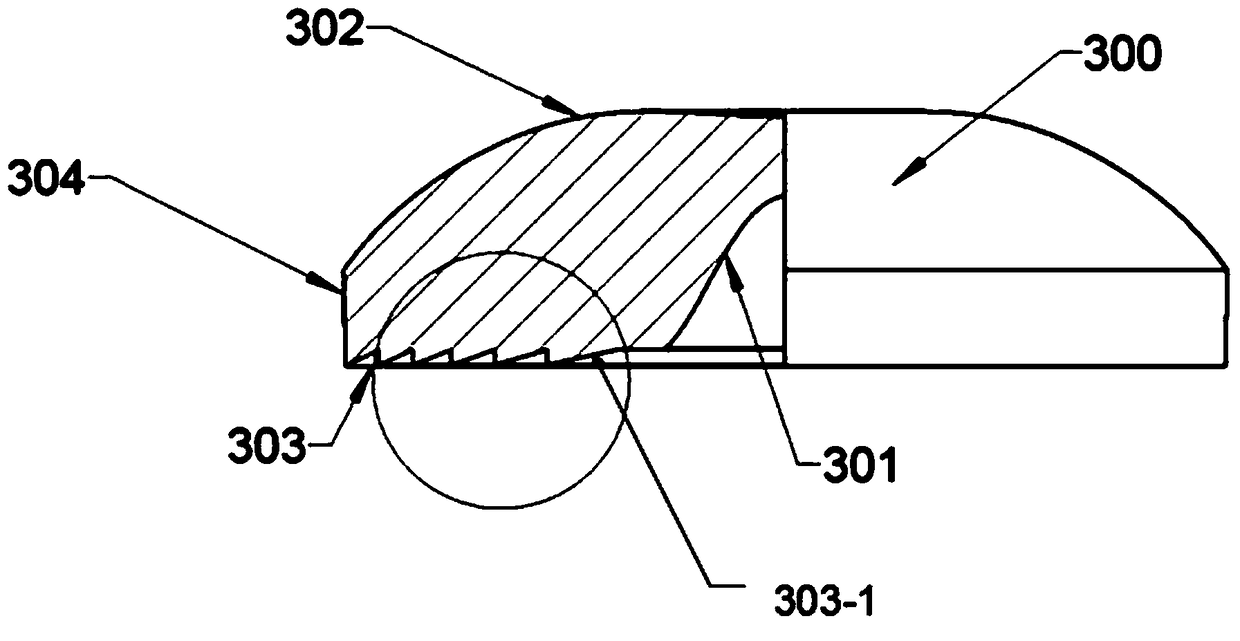

[0148] The bottom composite surface of the backlight lens in this embodiment includes a sub-composite surface, and the normal line of any point on the section of the sub-composite surface intersects with the central axis of the lens body below the lens body. In this embodiment, The lens structure in is simple and easy to mass-produce; such as Figure 6 , Figure 7 and Figure 8 shown (where Figure 6 is a schematic diagram of the three-dimensional structure of the present embodiment; Figure 7 is a schematic sectional view of the present embodiment; Figure 8 is the bottom view of the present embodiment). The rest of the structure and working principles of this embodiment are the same as those of the above-mentioned specific implementation, and will not be repeated here.

Embodiment 2

[0150] The bottom composite surface included in the backlight lens in this embodiment includes 6 sub-composite surfaces, the section line of the bottom composite surface is zigzag, and the zigzag root of the section line of the bottom composite surface is located on the same straight line, which is the same as this line. The central axis of the lens body described in the embodiment is vertical; and the section line of the sub-composite surface is a straight line structure, not only that, the arrangement of the sub-composite surfaces is denser as it gets closer to the edge of the lens body, such as Figure 9 , Figure 10 , Figure 11 shown (where Figure 9 is a schematic diagram of the three-dimensional structure of the present embodiment; Figure 10 is a schematic sectional view of the present embodiment; Figure 11 is the bottom view of this embodiment), and the rest of the structure and working principle of this embodiment are the same as those of the above-mentioned spec...

Embodiment 3

[0152] The bottom composite surface included in the backlight lens in this embodiment includes 6 sub-composite surfaces, the section line of the bottom composite surface is zigzag, and the zigzag root of the section line of the bottom composite surface is located on a curve, any point on the curve The closer to the central axis of the lens body, the greater the distance from the bottom surface of the lens; and the section line of the sub-composite surface is a straight line structure, and not only that, the arrangement of the sub-composite surfaces is denser the closer to the edge of the lens body, such as Figure 12 and Figure 13 shown (where Figure 12 is a schematic perspective view of this embodiment, Figure 13 is a schematic cross-sectional view of this embodiment), and the rest of the structure and working principle of this embodiment are the same as those of the above-mentioned specific implementation, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com