Automatic online washing device and automatic online washing method of water cooling water chilling unit tube-shell heat exchanger rubber ball

A kind of technology of shell-and-tube heat exchanger and chiller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

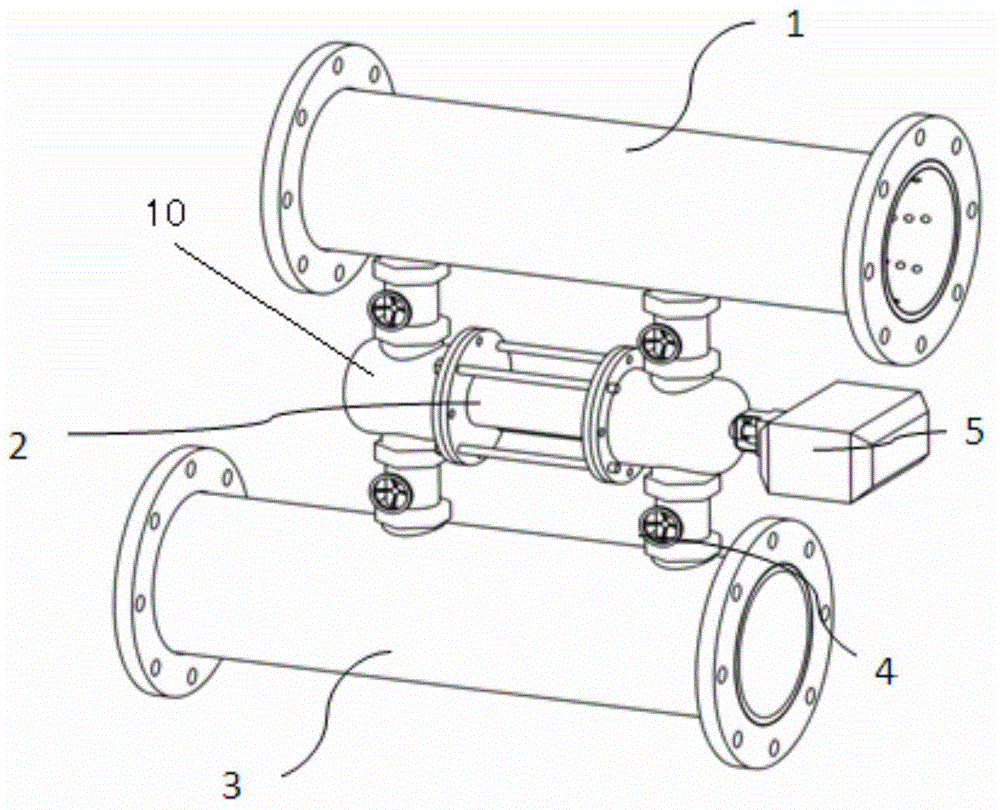

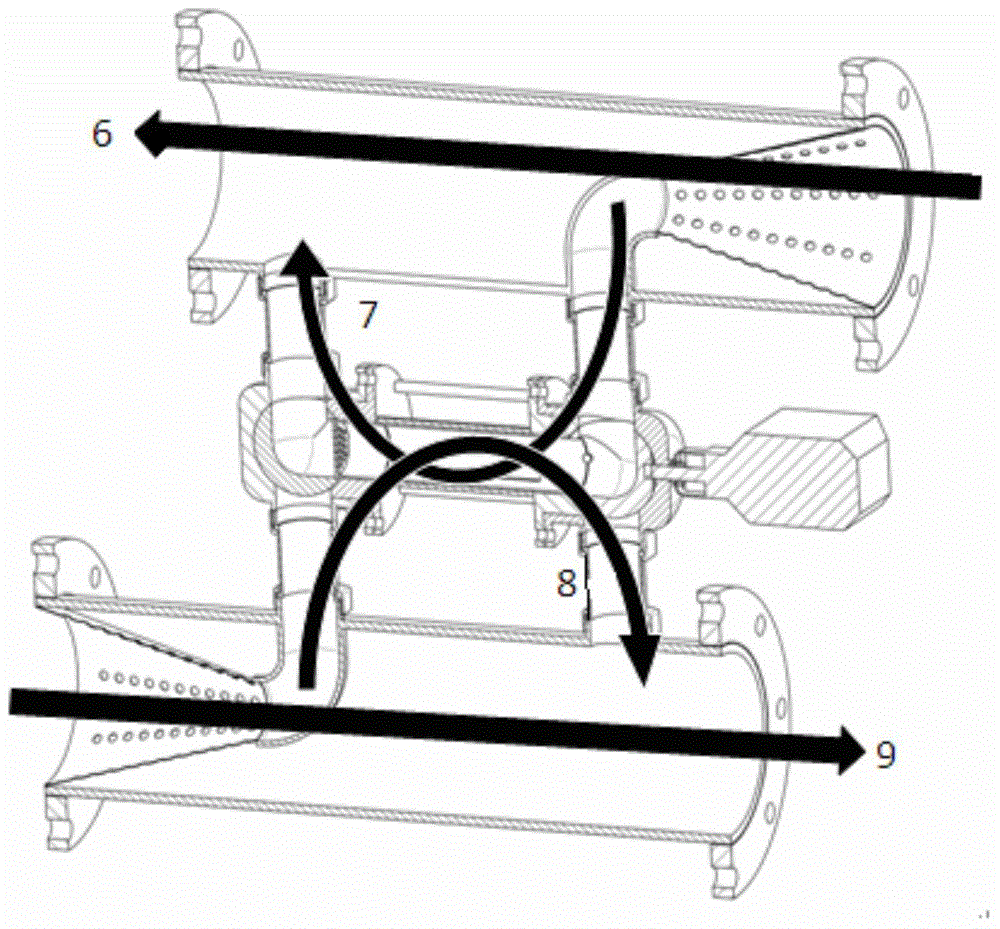

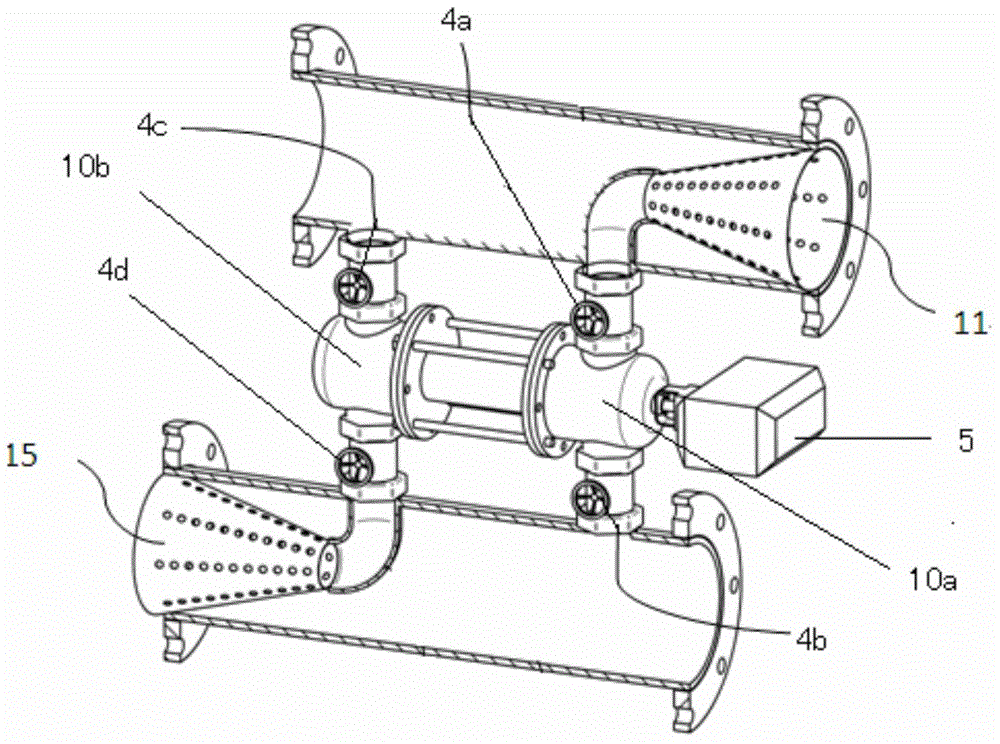

[0022] see Figure 1 to Figure 4 , an automatic online cleaning device for rubber balls of shell-and-tube heat exchangers of water-cooled chillers, including a ball receiving cylinder 1, a ball storage cylinder 2, a ball injection cylinder 3, a manual ball valve 4, an electric ball valve actuator 5 and a three-way ball valve 10; The three-way ball valve 10 is an L-shaped three-way ball valve, including a three-way ball valve one 10a and a three-way ball valve two 10b; The incoming end of described receiving ball tube 1 is provided with collecting ball filter screen 11, and the incoming end of described injection tube 3 is provided with water intake anti-ball filter screen 15; Collecting ball filter screen 11 and water intake anti-ball filter screen 15 are provided with a number of filter holes; the two ends of the ball storage tube 2 are respectively provided with three-way ball valves 10a, 10b, and the two ends of the ball storage tube 2 are respectively connected with the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap