Structural part remaining life predicting method based on multi-factor fusion correction

A technology of life prediction and structural parts, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of narrow application range and the inability to guarantee the accuracy of fatigue life estimation, and achieve accurate and effective prediction and the accuracy of prediction results Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

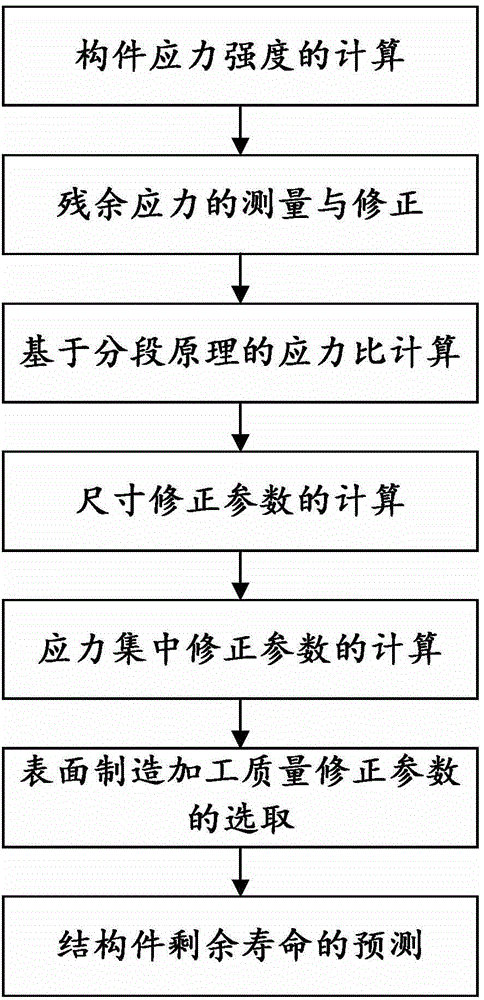

[0023] see figure 1 As shown, the present invention discloses a crack propagation prediction method for structural parts based on multi-factor fusion correction.

[0024] The method includes the following steps:

[0025] A method for predicting the remaining life of structural parts based on multi-factor fusion correction, characterized in that the method includes the following steps:

[0026] S1. Calculation of member stress intensity

[0027] Establish the 3D model of the analysis component according to the drawings, import the established 3D model into the finite element software, and complete the pre-processing of the finite element analysis of the component according to the steps of grid division, constraint setting, and load application. After the pre-processing is completed, the limited application Meta-analysis software analyzes its stress intensity to obtain its stress state distribution;

[0028] S2. Measurement and correction of residual stress

[0029] Measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com