Feature extraction multi-objective optimization method for wear condition of milling tool

A multi-objective optimization, wear state technology, applied in manufacturing tools, metalworking mechanical parts, measuring/indicating equipment, etc., to avoid the effect of low prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail below in conjunction with accompanying drawing:

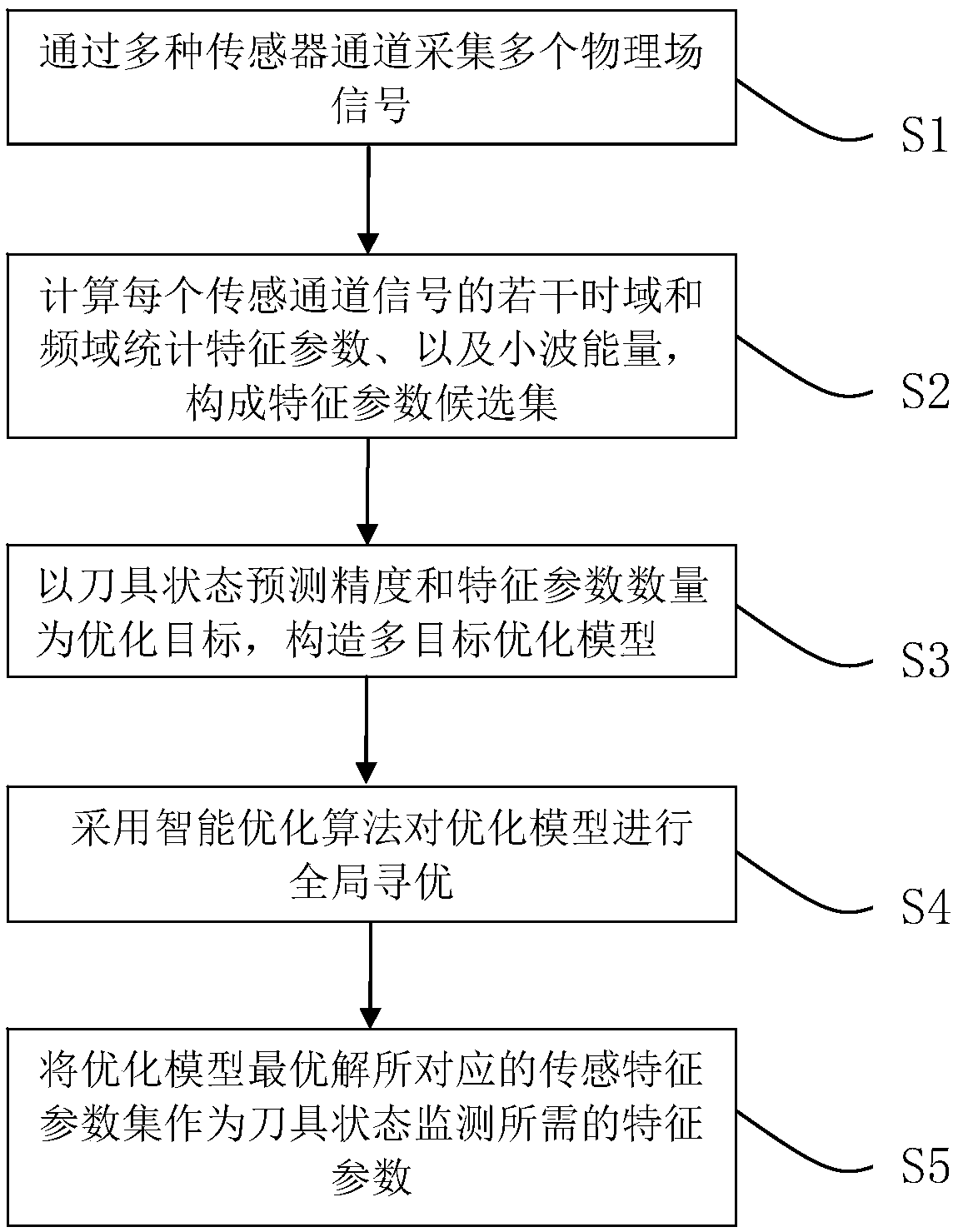

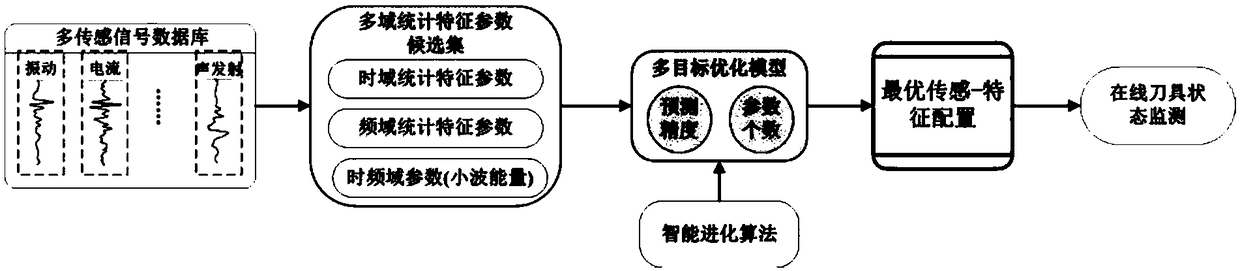

[0041] Such as figure 1 with figure 2 As shown, in the embodiment of the present invention, a multi-objective optimization method for feature extraction of milling tool wear state is proposed, which includes the following steps:

[0042] S1. Collect multiple physical field signals through multiple sensor channels. It mainly includes:

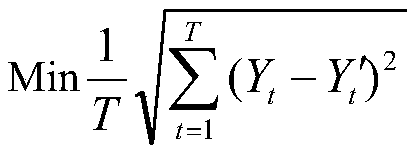

[0043] For new cutting tools, periodically collect the time-domain signals of sensing channels of S physical fields (such as vibration, current, acoustic emission, cutting force, sound, etc.) and the corresponding tool wear under the tool running state, and collect T times to form a training sample set (X, Y)={(X t ,Y t )}, X t ∈ R N×T , Y t ∈R,t=1,2,...,T,X t =(x 1t ,...,x St ) represents the signals of all S sensing channels when the signal is collected for the tth time, Y t Indicates the corresponding tool wear amount whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com