Movable patch board based on sliding mechanism

A sliding mechanism and movable technology, which is applied to the parts, electrical components, coupling devices and other directions of the connecting device, can solve the problem of jack movement, etc., and achieve the effect of full utilization, simple structure, intelligent and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

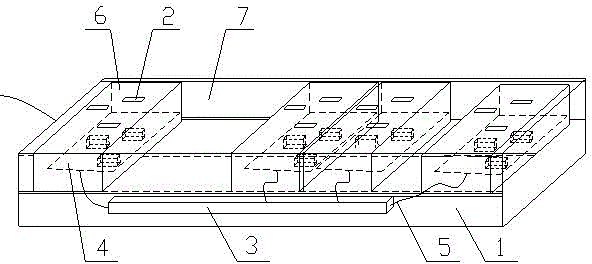

[0025] The socket board of this implementation includes a housing 1, a jack 2 and a control circuit board 3 connecting the jack 2, and also includes a sliding mechanism, the sliding mechanism is as follows: figure 1 As shown, it includes two slide rails 7, four jack shells 6, and 4 sets of interface circuits 4 for connecting the electric pieces inserted from the jack shells 6, wherein the jacks 2 are arranged in each jack shell 6 surface; the interface circuit 4 is fixedly arranged in each jack shell 6, and the interface circuit 4 is connected with the control circuit board 3 through the wire 5; the slide rail 7 is fixedly arranged on the inner wall of the housing 1, and each The jack shell 6 is slidably engaged on the slide rail 7 .

[0026] In this example, if figure 1 As shown, there are two slide rails 7, which are arranged on the inner wall of the housing 1 in parallel. There can be two slide rails 7 in the sliding mechanism, so that the two ends of the socket housing 6...

Embodiment 2

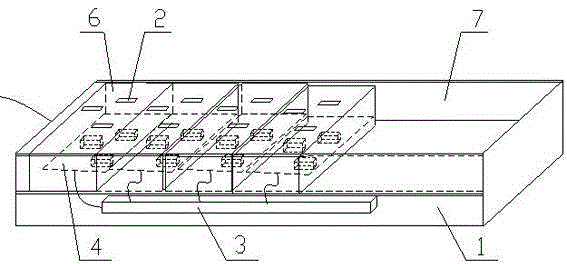

[0028] The socket board of this implementation includes a housing 1, a jack 2 and a control circuit board 3 connecting the jack 2, and also includes a sliding mechanism, which includes a slide rail 7, four jack shells 6 and a Connect 4 groups of interface circuits 4 that are inserted into electric sheets from the jack shell 6, wherein the jack 2 is arranged on the surface of each jack shell 6; the interface circuit 4 is fixedly set in each jack shell 6, and the The interface circuit 4 is connected to the control circuit board 3 through wires 5 ; the slide rail 7 is fixedly arranged on the inner wall of the housing 1 , and each jack shell 6 is slidably clamped on the slide rail 7 . Different from the above-mentioned embodiments, the surface of the jack shell 6 is arranged with three-pin jacks and two-pin jacks, and the number is not limited to the number in the figure. Users can feel that the surface of the jack shell 6 covers Number and orientation of jacks. Therefore, the sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap