Motor with Thrust Bearing

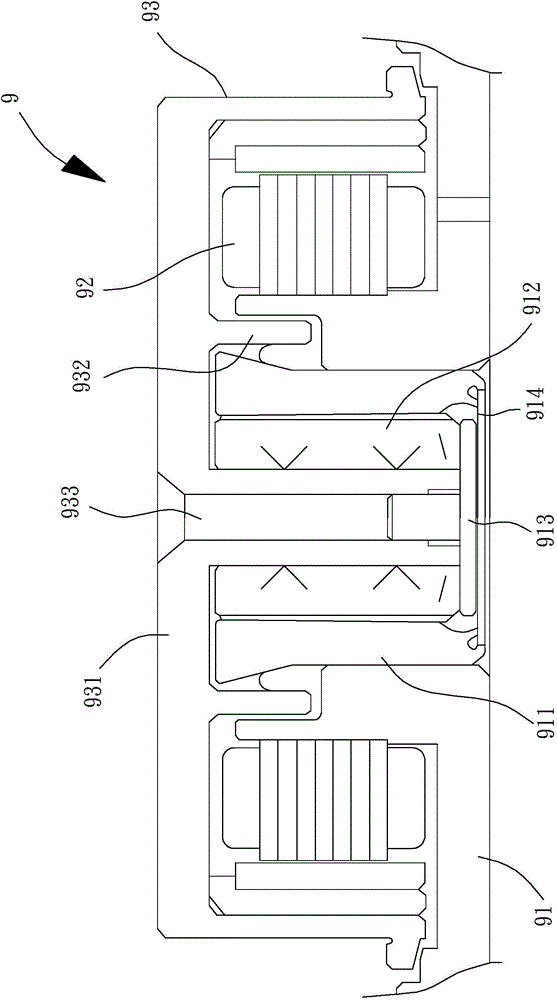

A technology for thrust bearings and motors, which is applied in the field of motors with thrust bearings, and can solve problems such as loosening or falling off of the rotor 93, lack of anti-oil leakage design, and inability of the thrust bearing 912 to effectively limit the position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

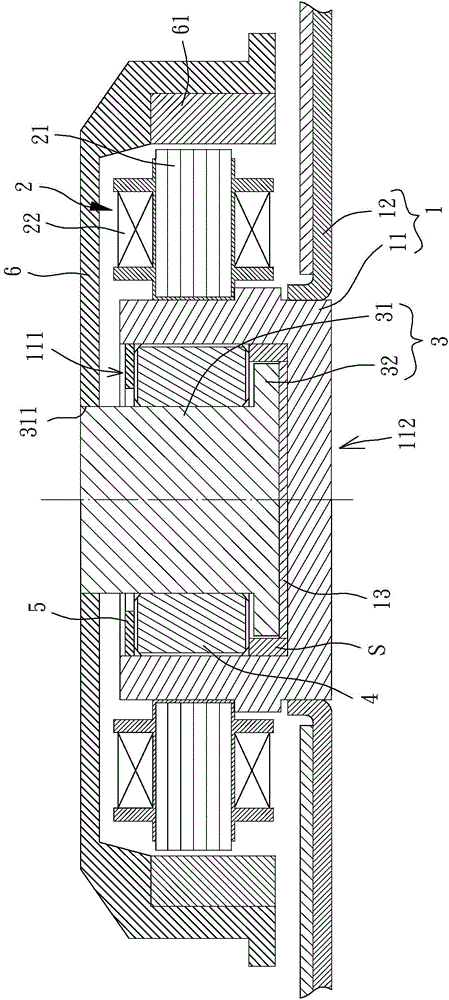

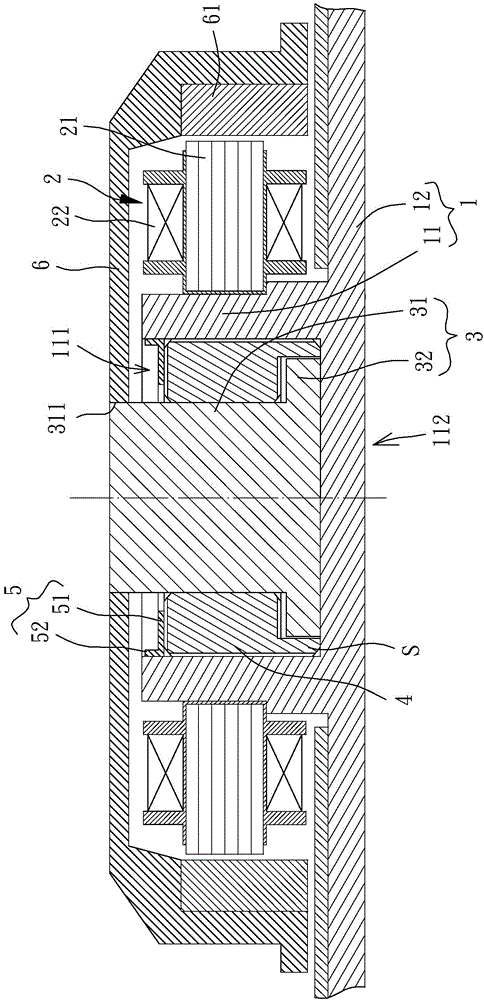

[0046] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0047] Please refer to figure 2 As shown, the motor with thrust bearing of the present invention at least includes a base 1 , a stator 2 , a rotating member 3 , a thrust bearing 4 , a pressing member 5 and a hub 6 . The stator 2 is combined with the base 1, the rotating member 3 is rotatably combined with the base 1 through the thrust bearing 4, the pressing member 5 is used to press and position the thrust bearing 4, and the hub 6 is combined on the rotating member 3.

[0048] The above-mentioned base 1 is provided with at least one bearing sleeve 11; in this embodiment, the base 1 includes the bearing sleeve 11 and a base plate portion 12, the bearing sleeve 11 and the base plate portion 12 are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com