Top rubber sulfuration die

A vulcanization mold and top glue technology, which is applied in the field of top glue vulcanization molds, can solve the problems of manual removal troubles, thick top glue burrs, etc., and achieve the effects of increasing work efficiency, reducing strength, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

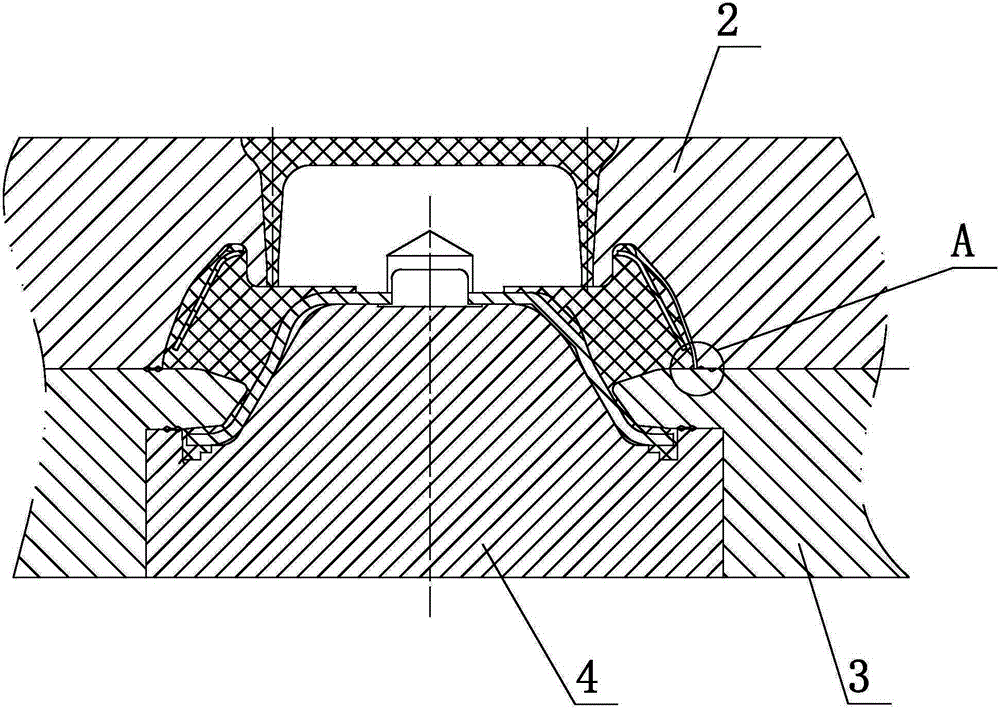

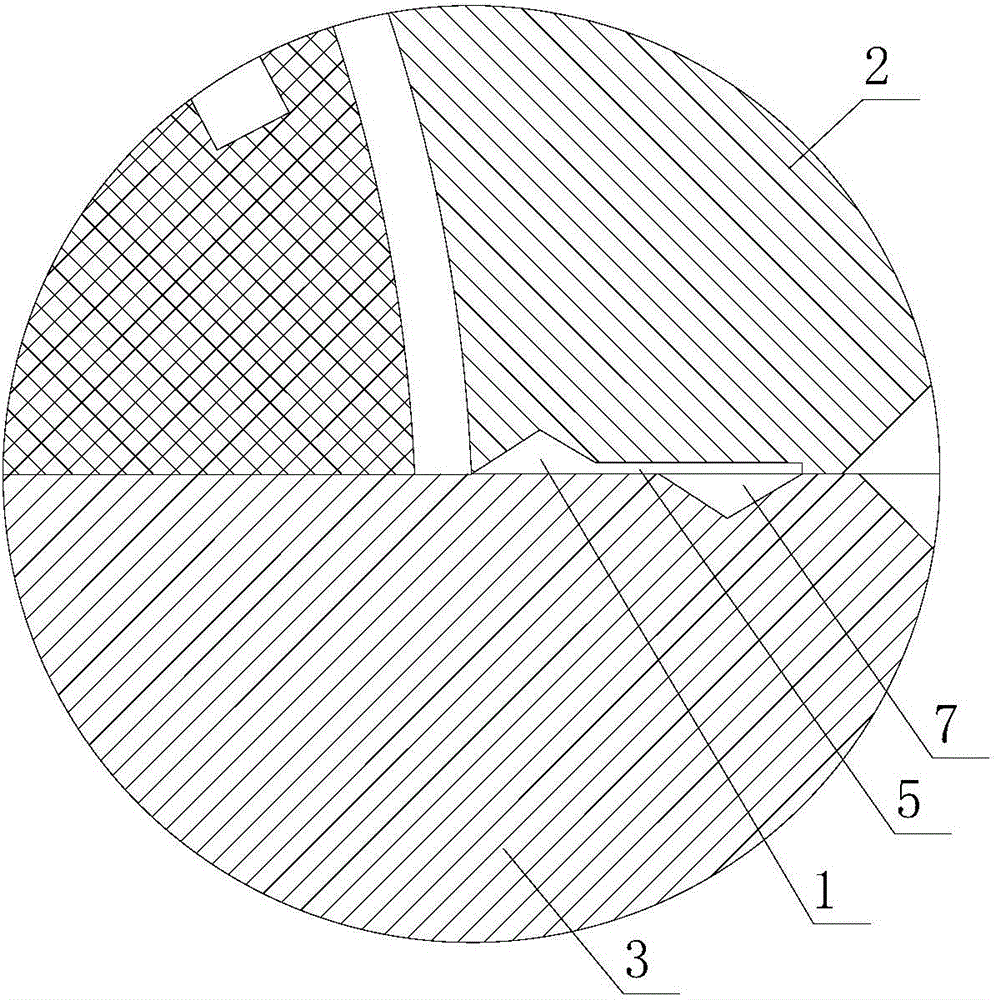

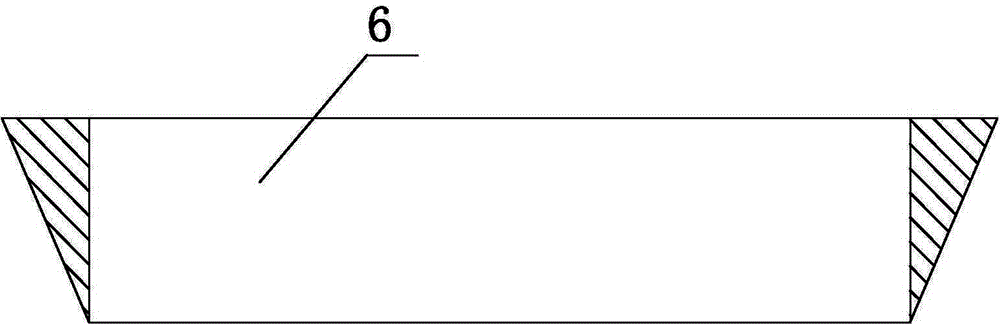

[0016] refer to figure 1 , figure 2 and image 3 , a top rubber vulcanization mold, comprising an upper mold 2, a lower mold 3, a mold core 4 pierced on the lower mold 3, the parting surface of the upper mold 2 and the lower mold 3 is provided with an annular overflow rubber groove 1 and the overflow glue groove 7, an annular passage 5 is arranged between the inner overflow glue groove 1 and the overflow glue groove 7. It also includes a cutting ring 6 for cutting burrs. The lower end of the cutting ring 6 is provided with a blade, and the longitudinal section of the cutting ring 6 is wedge-shaped. The inner overflow glue groove 1 is arranged on the upper mold 2, and the longitudinal section of the inner overflow glue groove 1 is a triangle with a small top and a large bottom. The overflow glue groove 7 is arranged on the lower mold 3, and the longitudinal section of the overflow glue groove 7 is a triangle with a large upper part and a smaller lower part.

[0017] When i...

Embodiment 2

[0019] refer to Figure 4 , the difference from Embodiment 1 is that the inner overflow glue groove 1 is composed of an upper annular groove arranged on the upper mold 2 and a lower annular groove arranged on the lower mold 3, and the longitudinal section of the upper annular groove is A triangle with a small top and a large bottom, the longitudinal section of the lower annular groove is a triangle with a large top and a small bottom; the structure of the overflow glue groove 7 is the same as that of the inner overflow glue groove 1 . , the excess rubber material enters the overflow glue groove 1, the annular channel 5 and the overflow glue groove 7 in sequence on the parting surface of the upper mold 2 and the lower mold 3. After the product is formed, take out the product and tear off the burrs by hand; Raw edges are thinner for easy tear-off.

[0020] The present invention adopts a double overflow groove structure. During the vulcanization injection process, the excess rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com