Electric flocculation device with inclined plate electrodes

A technology of inclined plate electrode and electrocoagulation, which is applied in the direction of flotation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

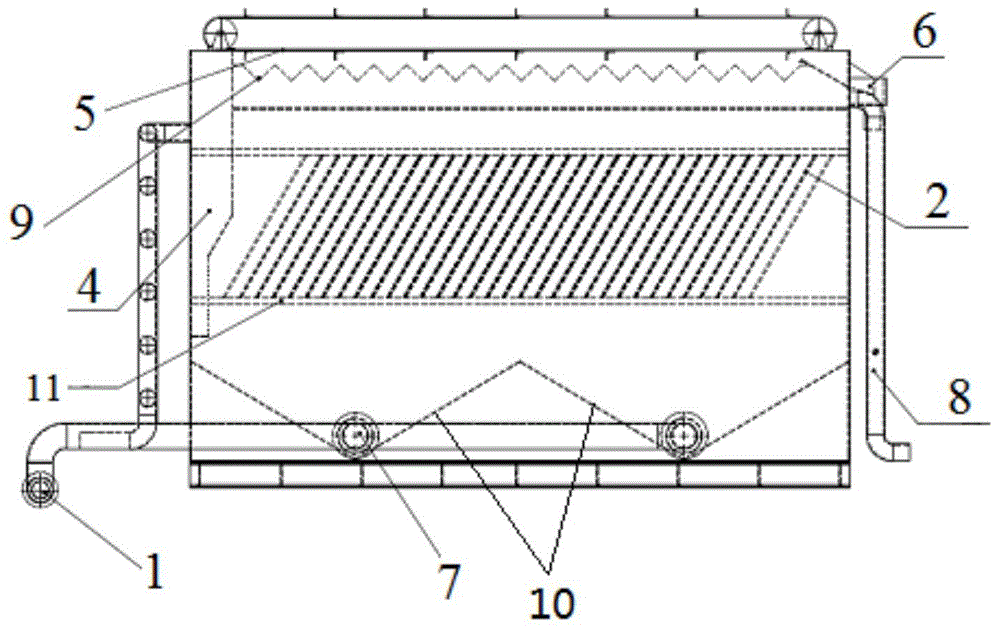

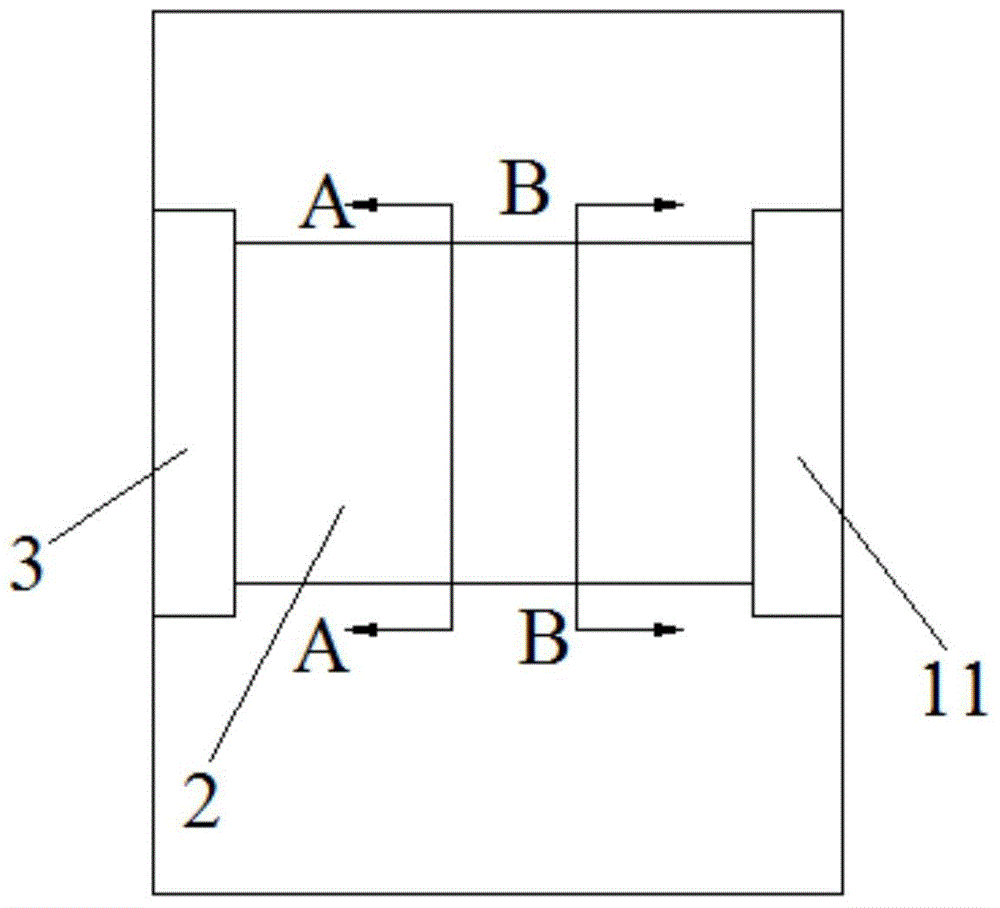

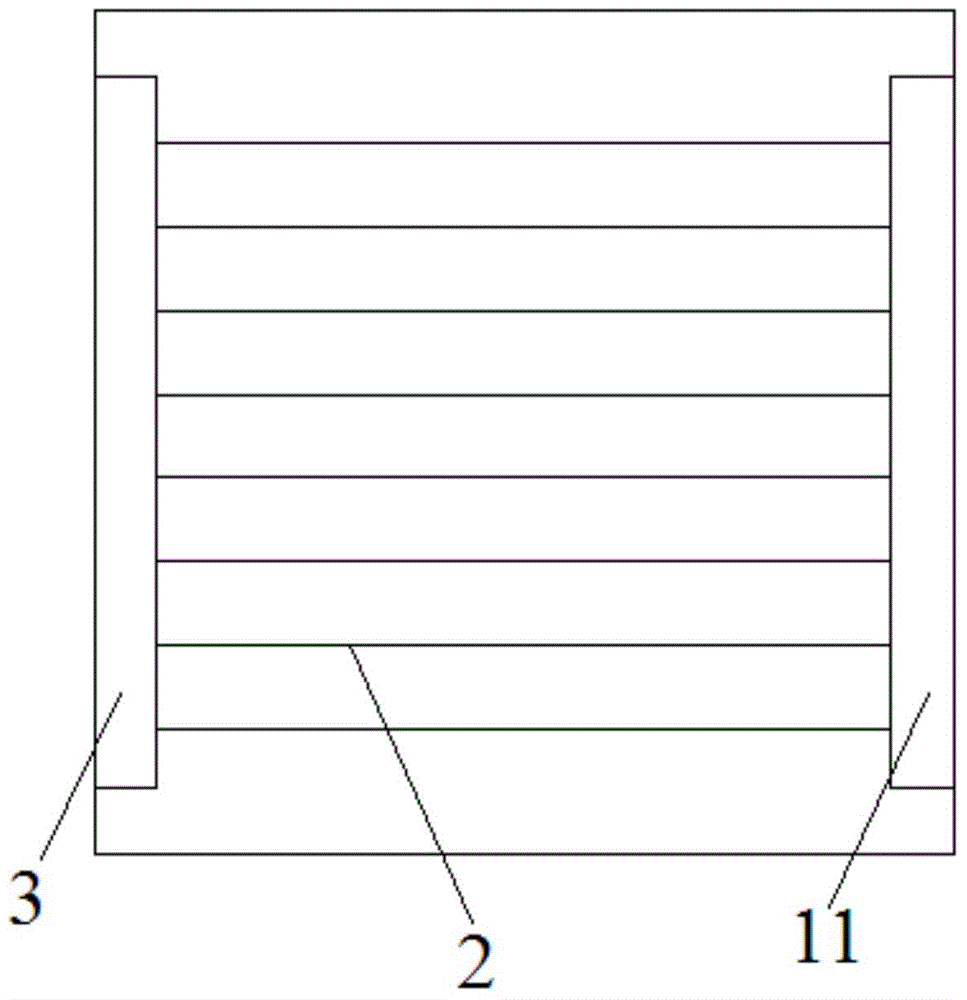

[0025] A kind of electric flocculation equipment with inclined plate electrode of the present invention, as figure 1 As shown, it includes a shell, an air flotation slag scraper 5 is arranged on the outside of the top of the shell, and a water inlet pipe 1 and an outlet pipe 8 are respectively installed on the left and right sides of the outer shell, the water inlet pipe 1 is a serpentine pipe, and the water outlet pipe 8 An oil slick recovery tank 6 is arranged above the top of the tank, and the oil slick recovery tank 6 is a metal plate welding tank. Weld a pipe through which the slick oil flows into a collection container. A water distribution distribution tank 4 is arranged on the side where the water inlet pipe 1 is installed in the housing. A slant plate electrode 2 is arranged inside the housing, and the slant plate electrode 2 is two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com