A kind of slow-setting adhesive for slow-bonding prestressed tendons and preparation method thereof

A slow-bonding prestressing and adhesive technology, which is applied in the field of building materials, can solve problems such as inability to stretch, insufficient retarding adhesive, high viscosity of retarding adhesive, etc., and achieve the effect of guaranteeing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the slow-bonding prestressed tendon provided by the embodiment comprises the following steps:

[0048] Step 1: kneading and stirring epoxy resin, organic oil, and dibutyl phthalate evenly under vacuum conditions to obtain the first mixture, and the kneading and stirring time is not less than 30 minutes;

[0049] Step 2: kneading and stirring the polyamide resin and N,N-dimethylethanolamine under vacuum conditions to obtain a second mixture;

[0050] Step 3: Knead and stir acetone, slag fine powder, the first mixture and the second mixture evenly under vacuum conditions to obtain a mixed material, and the kneading and stirring time is not less than 30 minutes;

[0051] Step 4: Use a three-roll machine to classify and grind the mixed material for three times, with the roller distances of each grinding being 1 mm, 0.5 mm, and 0.1 mm in turn, to obtain a slow-setting adhesive for slow-bonding prestressed tendons.

[0052] The preparation of the sl...

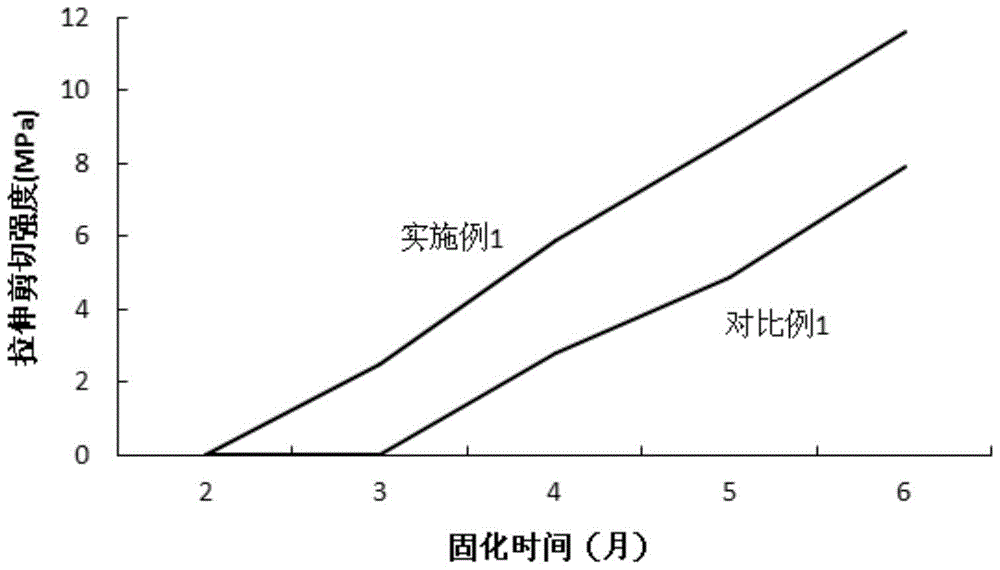

Embodiment 1

[0054] The present embodiment provides a retarding adhesive, which comprises the following compositions in parts by weight:

[0055] 30 parts by weight of epoxy resin (viscosity 8Pa·s), 2 parts by weight of organic oil, 2 parts by weight of polyamide resin (viscosity 15Pa·s), 1 part by weight of N,N-dimethylethanolamine, dibutyl phthalate 8 parts by weight of ester, 2 parts by weight of acetone and 58 parts by weight of slag fine powder.

[0056] The organic oil in this embodiment is at -10 ℃ and 10S -1 Under the condition of similar viscosity is the semi-fluid lithium grease of 80Pa · s, and the organic grease in the following examples and comparative examples is all identical with this.

[0057] The curing time of the retarding adhesive is 6 months, which is suitable for the production temperature below 25°C.

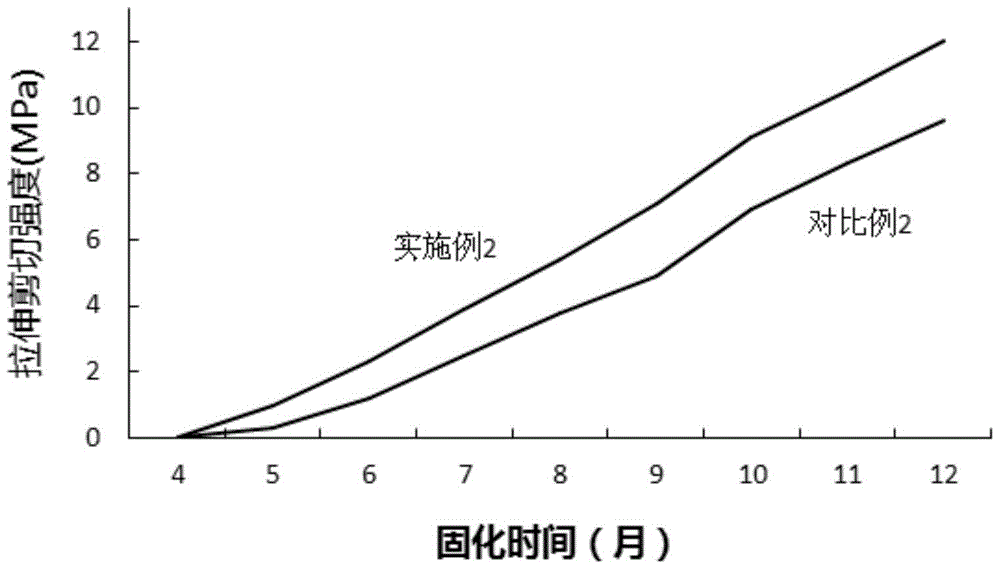

Embodiment 2

[0065] The present embodiment provides a retarding adhesive, which comprises the following compositions in parts by weight:

[0066] 35 parts by weight of epoxy resin (viscosity 10Pa·s), 4 parts by weight of organic oil, 1 part by weight of polyamide resin (viscosity 20Pa·s), 0.5 part by weight of N,N-dimethylethanolamine, dibutyl phthalate 4 parts by weight, 4 parts by weight of acetone and 60 parts by weight of slag fine powder.

[0067] The curing time of the retarding adhesive is 12 months, which is suitable for the production temperature below 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com