Bio-organic fertilizer with chitin and preparation method of bio-organic fertilizer

A bio-organic fertilizer and chitin technology, which is applied in the treatment of bio-organic parts, organic fertilizers, inorganic fertilizers, etc., can solve the problems of stinky shrimp shells, affecting transportation, and high recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method of preparing a biological organic fertilizer having a chin, which is suitable for use in the above-described biological organic fertilizer, including the following preparation steps:

[0036] S1: First, pour the shrimp shell after the edible shrimp shell into the shell processor, by flushing, stirring, pulverizing, filtration, and drying, after drying;

[0037] S2: The shrimp shell is then submerged, the acid solution and the alkali treatment are subjected to decalcination and deprotein treatment to obtain a matrix, and the resulting chin and crop straw, livestock feces, 蚓 dung, organic carbon, raw lime , Humic acid and grass ash are mixed well, resulting in mixing;

[0038] S3: Add a composite microbacterial agent to the mixture obtained in S2, and thoroughly stirred again, then the mixture obtained after stirring is added to the fermentation apparatus, and fermentation is carried out. After the fermentation is completed, the fermentation product is post-treatment...

Embodiment 1

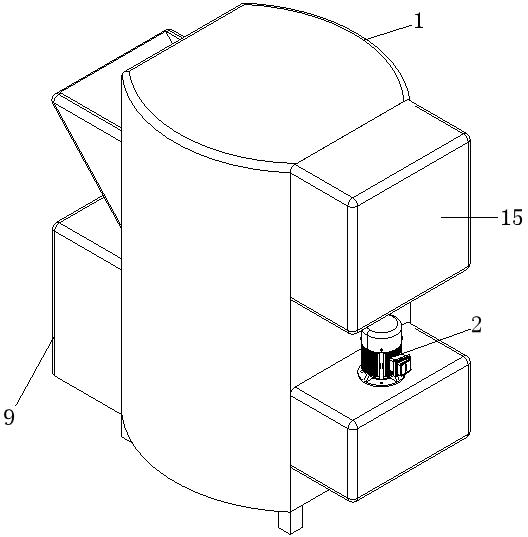

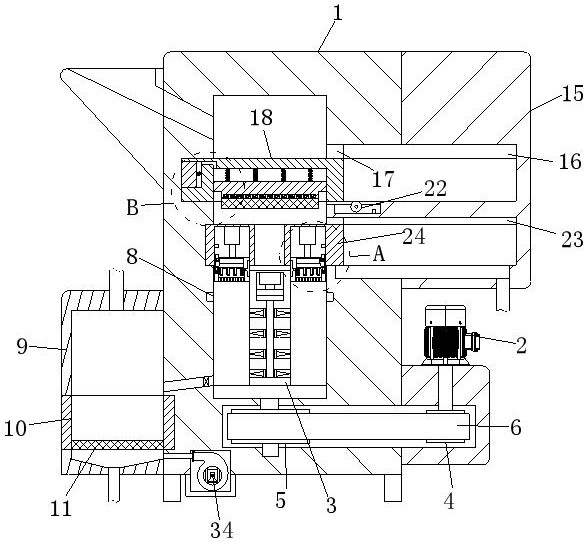

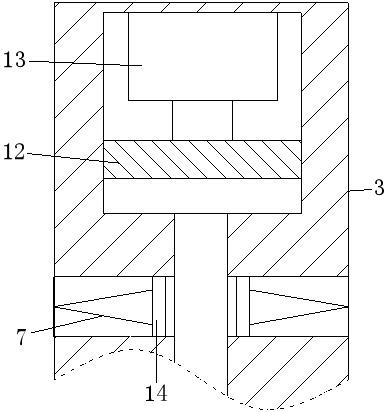

[0040] See Figure 1-5 As shown in, the shell type processor used in S1 includes a casing 1, a motor 2, and a stirrup post; the outer portion of the housing 1 has a motor 2; the output shaft of the motor 2 has a first turntable 4; the inside of the casing 1 is rotated to the bottom position of the casing 1 is connected to the second turntable 5; the first turntable 4 and the second turntable 5 are connected between the transmission belt 6; the top of the second turntable 5 Stirring column 3; the surface of the agitating column 3 is provided with a uniformly arranged cutter 7; the inside of the housing 1 has a spray head 8; the side solid connection of the casing 1 has a fixed block 9; The inside of the fixing block 9 is provided with a cassette 10; the bottom of the box 10 has a filter plate 11; there is a conductor hole between the inside of the casing 1 and the inside of the fixed block 9; The inside of the conductor is provided with a control valve; when operating, the main ingr...

Embodiment 2

[0049] See Image 6 Design, the inner side surface of the casing 1 is adjacent to the bottom surface of the connecting block 18, there is a turning hole in the bottom surface of the connecting block 18, and a groove is opened in the back of the reflow hole; the internal rotation of the groove is rotatable. 35; When working, by setting a reflow hole, the liquid surface of the shrimp shell is floated due to the cleaning, these light impurities should not be adsorbed by the cotton 21, and it will also hinder the oil absorption effect of cotton 21, when connected When the block 18 is exported, the connecting block 18 can move the transfer plate 35, and the shrimp housing can be cleaned by the transfer plate 35, promoting the light impurities of the shrimp section to be derived by reflow holes, and the rotating plate 35 of the rotation is not An interference is generated between the pressure plate 22, and the excess shrimp shell can also be derived by the backflow hole, and it is especi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com