A kind of high-concentration organic carbonic acid fermented liquid and its preparation method and application

A fermented liquid and high-concentration technology, applied in the field of fermented liquid, can solve the problems of high glucose and fructose content of enzyme foliage fertilizer, fast effect decline speed, large effect drop, etc., achieve high antioxidant capacity, prolong storage time, Mild and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

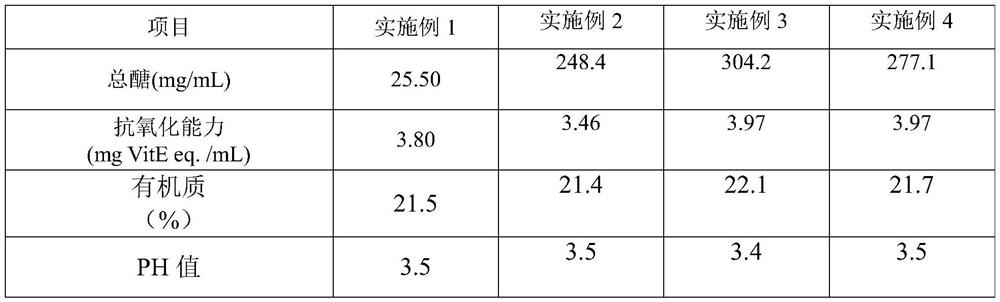

Examples

Embodiment 1

[0027] In the fermentation tank, a tap water passed through the active carbon filtration, a glucogene, a sugar and 67 kg of sugar, stirred to sugar, completely dissolved to form sugar water, and add soybeans 5 kilograms of soybean water to dissolve the solution, put it into The first comprehensive fermentation bacterium is 2 kg, stir well; from the first day of the fermentation day, stirring the next day, stir, once a day, each mixing time is 5-10 minutes. Under the environment of temperature at 30 ° C, the fermentation period is thrown during the 5th day, and the fermentation liquid exhibits boiling, and stirring can be stopped after entering the mandatory period. After 2 kg of the second fermenting bacteria was put into a second fermentation bacterium on the 10th day; the third fermentation bacteria was put into the third fermentation bacteria. After the fermentation was completed, the fermentation liquid was filtered into a clean storage barrel, and the gas was allowed to be se...

Embodiment 2

[0029] In the fermentation tank, a tap water passed through the active carbon filtration, 77 kilograms of sugar, and 77 kg, stir to sugar to completely dissolve the formation of sugar water, and add the soybean 10 kg of yellow beans to the dissolved sugar water, invest The first comprehensive fermentation bacteria, stir well; at the first day of the fermentation day, stirring the next day, stir, once a day, each mixing time is not less than five minutes. Under the environment where 25 ° C is 25 ° C, the fermentation period is thrown during day 7, the fermentation liquid exhibits boiling, and stirring can be stopped after entering the prosperous period. After 2 kg of the second fermenting bacteria was put into a second fermentation bacterium on the 10th day; the third fermentation bacteria was put into the third fermentation bacteria. After the fermentation was completed, the fermentation liquid was filtered into a clean storage barrel, and the gas was allowed to be sealed. It is r...

Embodiment 3

[0031] In the fermentation tank, a tap water passed through the active carbon filtration, 71 kg of sugar, and 71 kg, stir to sugar, completely dissolved to form sugar water, and add soy 8 kilograms of yellow beans to dissolve the dissolved sugar water, invest The first comprehensive fermentation bacteria, stir well; at the first day of the fermentation day, stirring the next day, stir, once a day, each mixing time is not less than five minutes. Under the 20 ° C temperature of the temperature, approximately 6th days, the fermentation is boiling, and the fermentation liquid can be stopped after entering the mandatory period. After 2 kg of the second fermenting bacteria was put into a second fermentation bacterium on the 10th day; the third fermentation bacteria was put into the third fermentation bacteria. After the fermentation was completed, the fermentation liquid was filtered into a clean storage barrel, and the gas was allowed to be sealed. It is riched into fermented, room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com