A kind of preparation method of bio-organic fertilizer with chitin

A bio-organic fertilizer and chitin technology, which is applied to the treatment of bio-organic parts, organic fertilizers, inorganic fertilizers, etc., can solve the problems of odorous shrimp shells, affecting transportation, and high recycling costs, so as to increase cavity and drought resistance, ensure production, and improve production efficiency. The effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of bio-organic fertilizer with chitin, the preparation method is applicable to the above-mentioned bio-organic fertilizer with chitin, comprising the following preparation steps:

[0036] S1: First, pour the remaining shrimp shells into the shell processing machine, rinse, stir, crush, filter and dry in the shell processing machine to obtain shrimp shell fragments;

[0037] S2: Then soak the shredded shrimp shells in acid solution and alkali solution successively, and perform decalcification and deproteinization treatment to obtain chitin, and combine the obtained chitin with crop straw, livestock and poultry manure, vermicompost, organic carbon, quicklime , humic acid and plant ash are fully mixed evenly to obtain a mixture;

[0038] S3: Add the compound microbial bacterial agent to the mixture obtained in S2, fully stir again, then add the mixture obtained after stirring into the fermentation device, and carry out fermentation. After the fermentat...

Embodiment 1

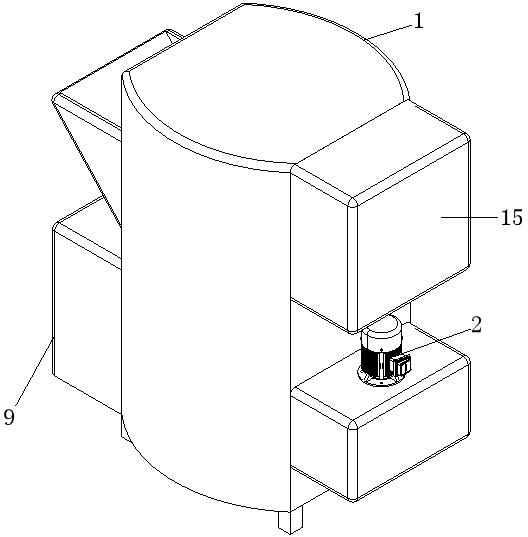

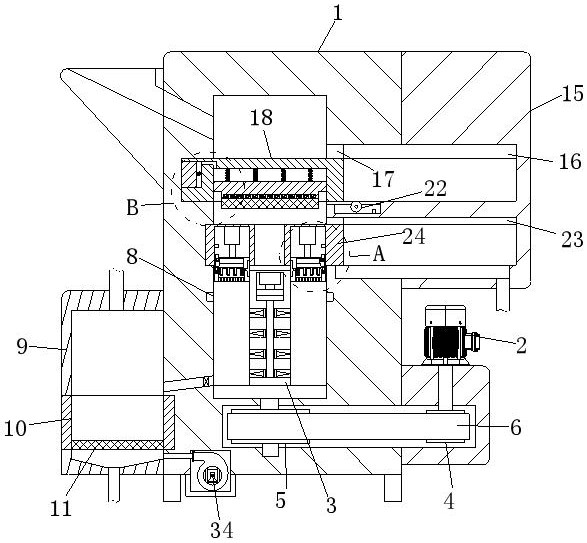

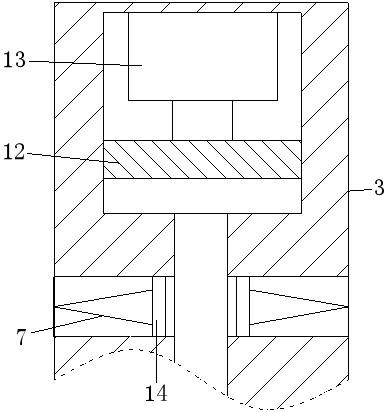

[0040] see Figure 1-5 As shown, the shell processing machine used in S1 includes a casing 1, a motor 2 and an agitating column 3; the outside of the casing 1 is fixedly connected with a motor 2; the output shaft of the motor 2 has a first turntable 4; the inside of the casing 1 is rotatably connected to a second turntable 5 near the bottom of the casing 1; a transmission belt 6 is connected between the first turntable 4 and the second turntable 5; the top of the second turntable 5 A stirring column 3 is fixedly connected; the surface of the stirring column 3 is provided with uniformly arranged cutters 7; the inside of the casing 1 is fixedly connected with a nozzle 8; the side of the casing 1 is fixedly connected with a fixed block 9; The inside of the fixed block 9 is provided with a storage box 10; the bottom of the storage box 10 is fixedly connected with a filter plate 11; a guide hole is provided between the inside of the casing 1 and the inside of the fixed block 9; Th...

Embodiment 2

[0049] see Figure 6 As shown, the inner side of the casing 1 is provided with a return hole near the bottom surface of the connection block 18; the bottom surface of the connection block 18 is provided with a rotary slot near the backflow hole; the internal rotation of the rotary slot is connected with a rotary plate 35; When working, by setting the return hole, since the liquid surface where the cleaned shrimp shell is located will float a lot of light impurities, these light impurities should not be absorbed by the absorbent cotton 21, and will also hinder the oil absorption effect of the absorbent cotton 21. When connected When the block 18 is exported, the connecting block 18 will drive the rotating plate 35 to move, the liquid surface of the shrimp shell can be cleaned by the rotating plate 35, and the light impurities on the liquid surface of the shrimp shell can be promoted to be exported through the return hole, and the rotating plate 35 in the rotating state will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com