Concrete spraying and painting integration tunnel construction device

A technology for concrete spraying and tunnel construction, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as insufficient automation, time-consuming and labor-intensive, and achieve the effect of reducing labor costs, reducing construction time, and eliminating deviations in construction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

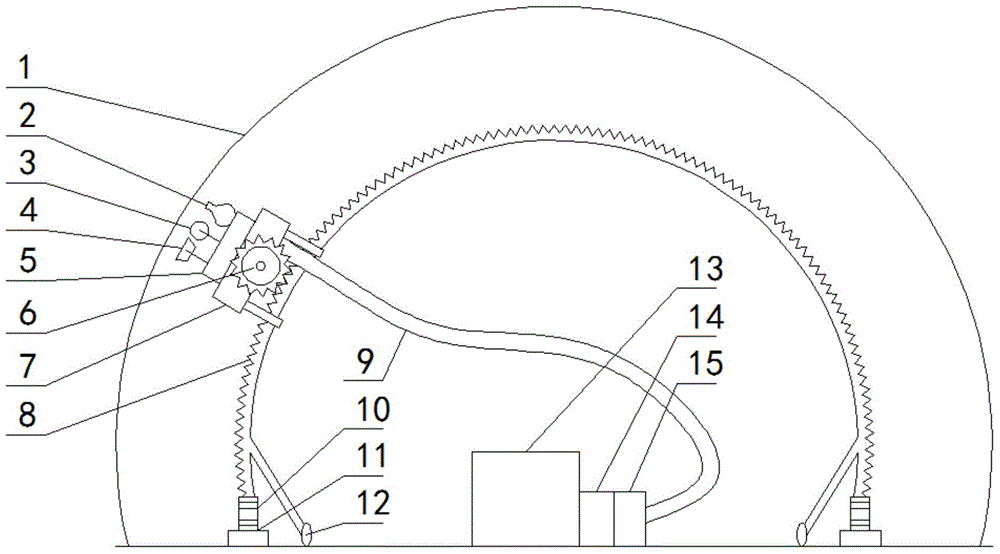

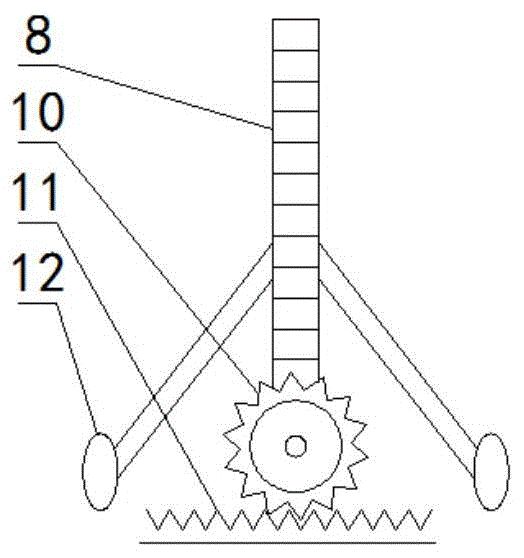

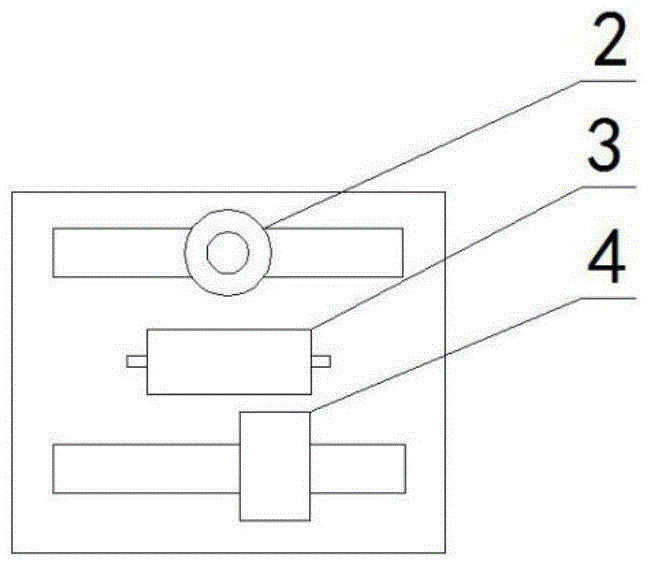

[0028] Such as Figure 1-6 As shown, an integrated tunnel construction device for concrete spraying and smearing according to the present invention includes a spray gun head 2, a smoothing roller 3, a smoothing brush 4, a rotating platform 5, two platform gears 6, a mobile platform 7, and two arc-shaped Track 8, transmission pipe 9, four track gears 10, two ground tracks 11, inclined support frame 12, mixer 13, screw propeller 14 and air pump 15; Wherein, described two ground tracks 11 are parallel to each other, by straight line The segment components are constructed and arranged along the direction of the tunnel, and the upper surface of the ground track 11 is a toothed structure.

[0029] The two arc-shaped tracks 8 are parallel to each other. The two arc-shaped tracks 8 are firmly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com