Adjustable nozzle ring structure of marine mixed-flow turbocharger

A turbocharger and mixed-flow technology, applied in the field of ships, can solve the problems of small operation range of the supercharger, inconvenient work adaptability and maintenance of the supercharger, difficult working range of the supercharger, etc. Compact, cleverly designed and effective in improving the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

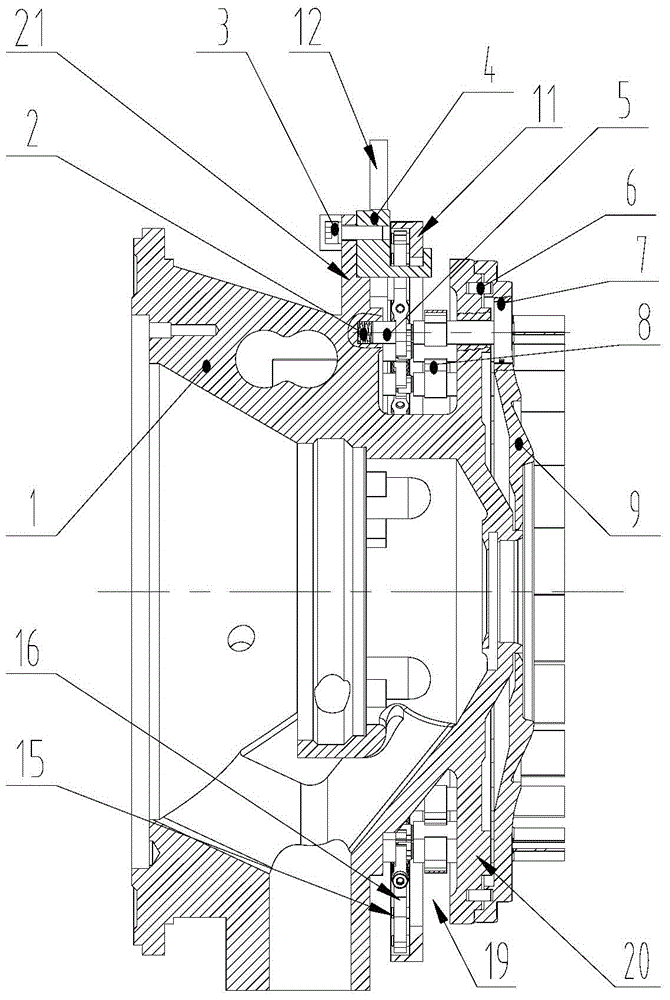

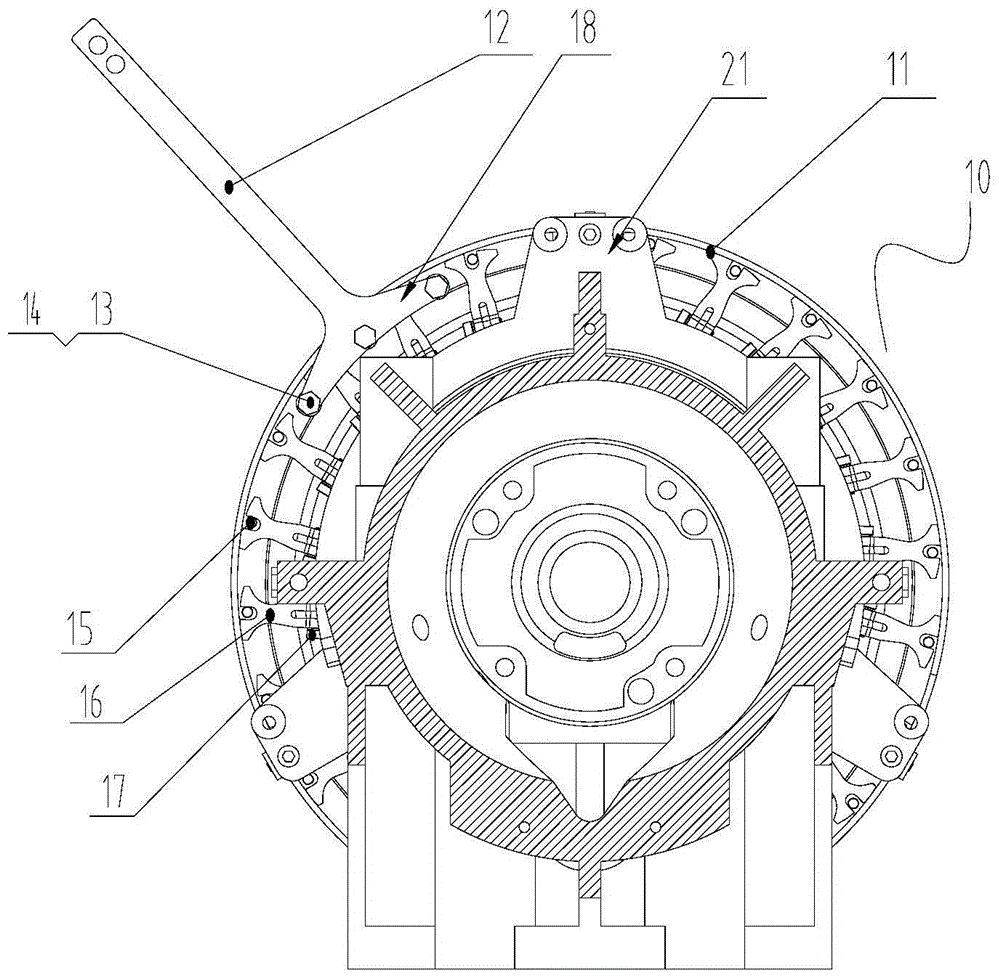

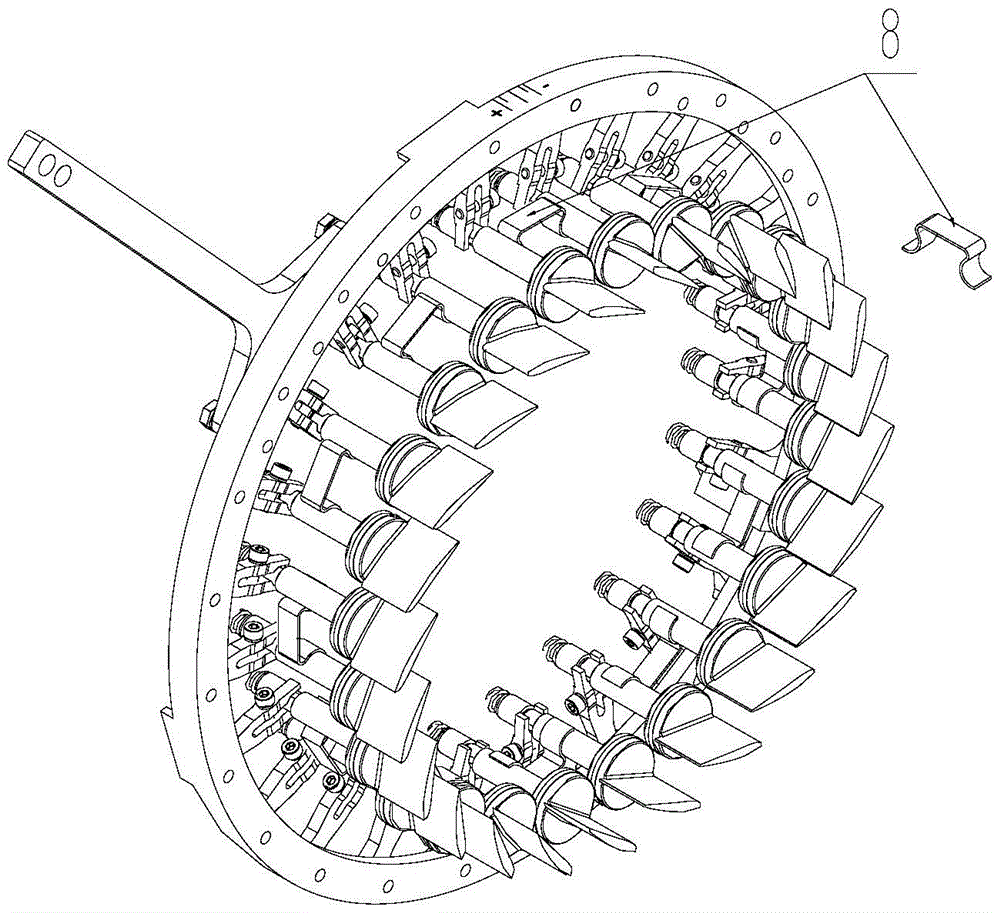

[0022] see Figure 1 to Figure 3 , is a preferred embodiment of the adjustable nozzle ring structure of the marine mixed-flow turbocharger, including a bearing shell 1, on which several nozzle ring vanes 5 are evenly arranged along the circumferential direction, and the The blade 5 includes a blade rotating shaft and a blade blade body fixed together. The axes of the rotating shafts of the blades 5 are all parallel to the axis of the bearing shell 1 , and the blades 5 are rotatably supported on the bearing shell 1 . In this embodiment, the connecting end of the bearing shell 1 is provided with an annular groove 19 along the circumference, so that an annular flange 20 is formed outside the annular groove 19 of the bearing shell 1, and the rotating shafts of the blades 5 pass through the annular flange respectively. 20. The annular groove 19 is in clearance fit with the mounting holes respectively provided on the bearing shell 1, and at the same time is in clearance fit with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com