Quality detection and evaluation method for light color lignite wax

An evaluation method and montan wax technology, applied in the field of coal chemical industry analysis, can solve the problems of inability to digitally manage and evaluate colors, lagging behind the actual demand of production, and not rising to establishment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

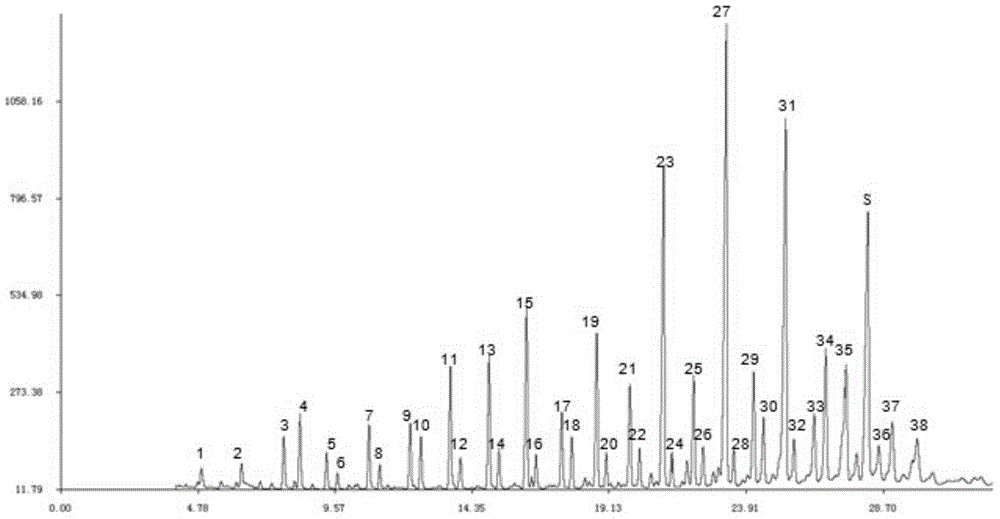

Embodiment 1

[0205] Quality control of light-colored montan wax (Taking Eshan light-colored montan wax and deresinized montan wax as an example, other origins are similar):

[0206] The gas chromatography fingerprint detection method of this light-colored montan wax and deresinized montan wax, its concrete steps comprise as follows:

[0207] (1) Gas chromatographic fingerprints of light-colored montan wax and deresinized montan wax to be measured:

[0208] (1) Preparation of the reference solution: Accurately weigh the n-hexadecane GC analysis standard with a content ≥ 99% and add toluene to prepare a solution with a concentration of 0.4 mg / mL, which is the reference solution;

[0209] (2) Preparation of the test solution: Precisely weigh 5 mg of the same batch of Asan deresinized montan wax and its light-colored montan wax samples into two 5mL vials with caps, and accurately add 2mL of toluene and 500μL of the reference substance solution were then capped, heated in each capped vial unti...

Embodiment 2

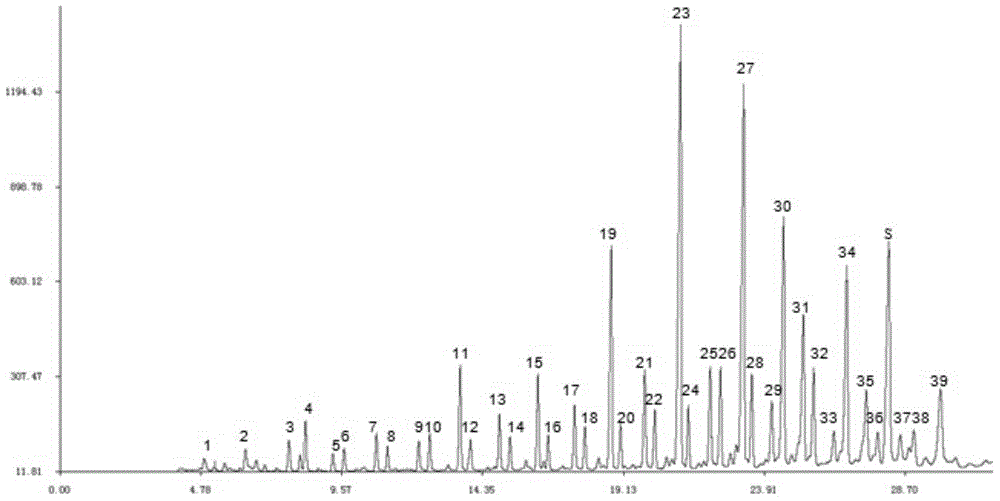

[0218] Identification of adulteration of light-colored montan wax (taking Xundian light-colored montan wax as an example, other places of origin are similar):

[0219] The gas chromatography fingerprint detection method of this light-colored montan wax, its concrete steps comprise as follows:

[0220] (1) Establishment of gas chromatographic standard fingerprints:

[0221] (1) Preparation of the reference solution: Accurately weigh the n-hexadecane GC analysis standard with a content ≥ 99% and add toluene to prepare a solution with a concentration of 0.4 mg / mL, which is the reference solution;

[0222] (2) Preparation of the test solution: Accurately weigh 5 mg of powdered light-colored montan wax sample and put it into a 5 mL vial with a cap, add 2 mL of toluene and 500 μL of the reference solution accurately in turn, and then cover it, and heat until the light-colored montan wax is completely After dissolving, carry out derivatization reaction for 45 minutes, then adjust to...

Embodiment 3

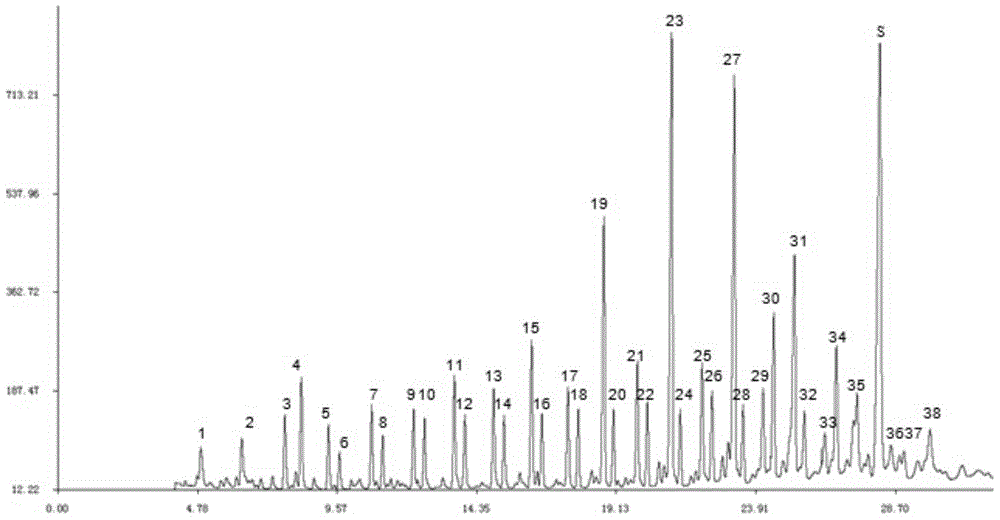

[0231] Origin of light-colored montan wax (Take light-colored montan wax from Zhaotong and Xundian as examples, other origins are similar):

[0232] The gas chromatography fingerprint detection method of this light-colored montan wax, its concrete steps comprise as follows:

[0233] (1) Establishment of gas chromatographic standard fingerprints:

[0234] (1) Preparation of the reference solution: Accurately weigh the n-hexadecane GC analysis standard with a content ≥ 99% and add toluene to prepare a solution with a concentration of 0.4 mg / mL, which is the reference solution;

[0235] (2) Preparation of the test solution: Accurately weigh 5 mg of powdered light-colored montan wax sample and put it into a 5 mL vial with a cap, add 2 mL of toluene and 500 μL of the reference solution accurately in turn, and then cover it, and heat until the light-colored montan wax is completely After dissolving, carry out derivatization reaction for 45 minutes, then adjust to the original 2mL l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com