Brightness enhancement film, preparation method therefor, and optical composite film

A technology of brightness enhancement film and optical film, applied in the field of optical film, can solve the problem of insufficient brightness gain of the brightness enhancement film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

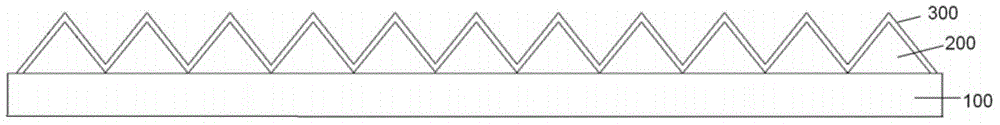

[0036] In addition, the present invention also provides a method for preparing a brightness enhancement film, which includes the following steps: forming a light concentrating layer 200 composed of a plurality of light concentrating structures on the upper surface of the substrate 100, the light concentrating structures having The upper surface of the 100 is in contact with the bottom surface, and the upper surface of the light-gathering layer 200 has a concave-convex structure; the refraction layer 300 is formed on the upper surface of the light-gathering layer 200, and the refraction layer 300 has the same surface as the light-gathering layer 200. A concave-convex structure that matches the concave-convex structure.

[0037] In the above preparation method provided by the present invention, a refraction layer 300 with a relatively high refractive index is attached on the upper surface of the light concentrating layer 200 . Since the light-gathering structure in the light-gat...

Embodiment 1

[0045] Substrate:

[0046] Using polyethylene terephthalate (PET) film as the substrate;

[0047] Production of light-concentrating layer:

[0048] A 9-inch self-made metal mother board is placed on a hot plate and heated to 60°C. The metal mother board is composed of linear arrangements of 90-degree isosceles triangular prisms with a nominal pitch interval of 50 microns. The UV-curable resin composition (refractive index: 1.6, see the table below for the composition) was applied to the master tool using a disposable pipette. Orient the PET film so that the orientation of the linear prisms is roughly perpendicular (90 ± 20°) to the high-gain axis of the film. The master tool, photocurable resin composition and PET film were then passed through a heated nip roll at 60° C., which applied sufficient pressure to completely fill the master tool with the resin while removing entrapped air. The filled master tool was then exposed twice to UV radiation from a "D-tube" at a line spe...

Embodiment 2

[0053] Substrate:

[0054] Using polyethylene terephthalate (PET) film as the substrate;

[0055] Production of light-concentrating layer:

[0056] A 9-inch self-made metal mother board is placed on a hot plate and heated to 60°C. The metal mother board is composed of linear arrangements of 90-degree isosceles triangular prisms with a nominal pitch interval of 50 microns. The UV-curable resin composition (refractive index: 1.52, see the table below for the composition) was applied to the master tool respectively using a disposable pipette. Orient the PET film so that the orientation of the linear prisms is roughly perpendicular (90 ± 20°) to the high-gain axis of the film. The master tool, photocurable resin composition and PET film were then passed through a heated nip roll at 60° C., which applied sufficient pressure to completely fill the master tool with the resin while removing entrapped air. The filled master tool was then exposed twice to UV radiation from a "D-tube"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com