Patents

Literature

35results about How to "High brightness gain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

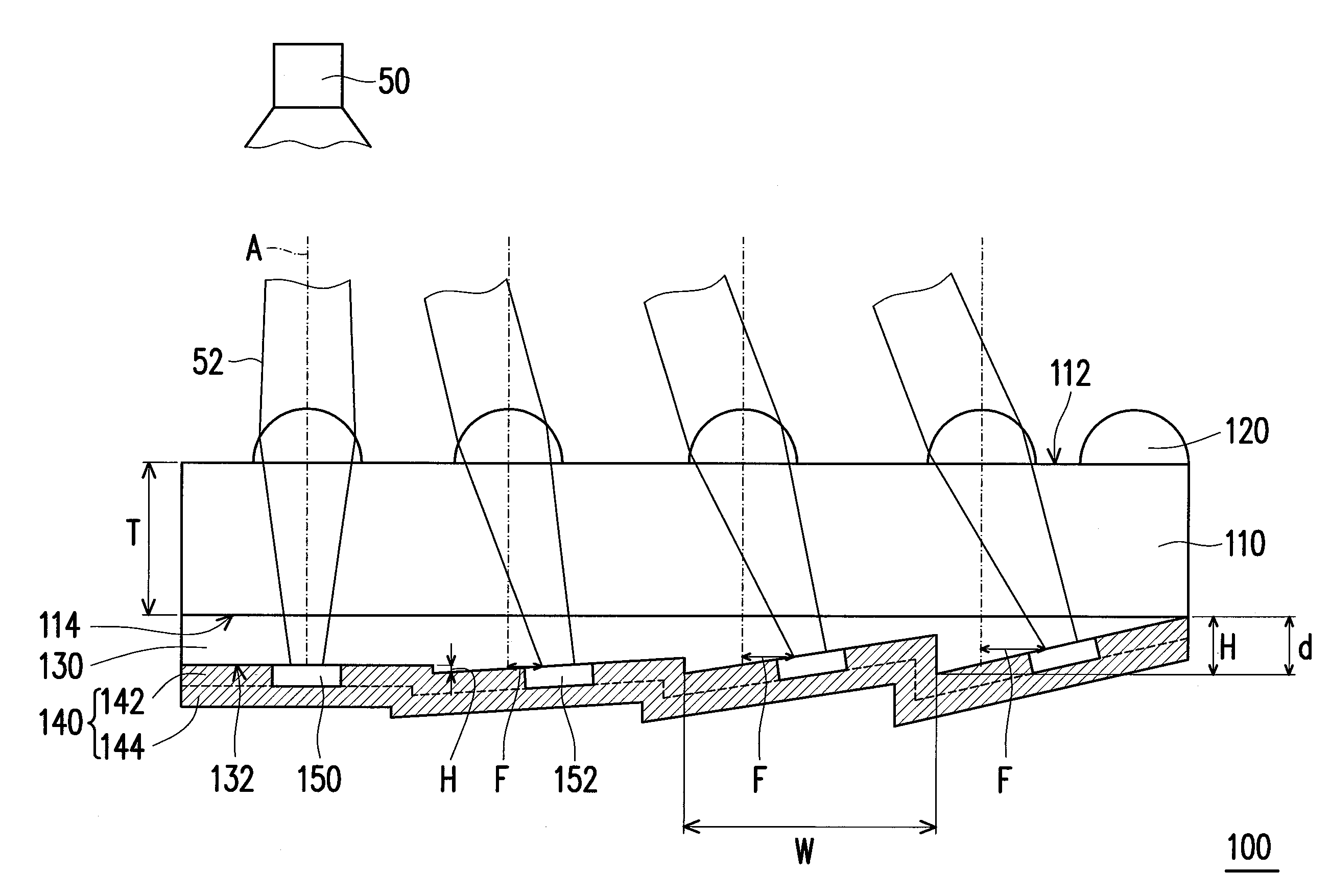

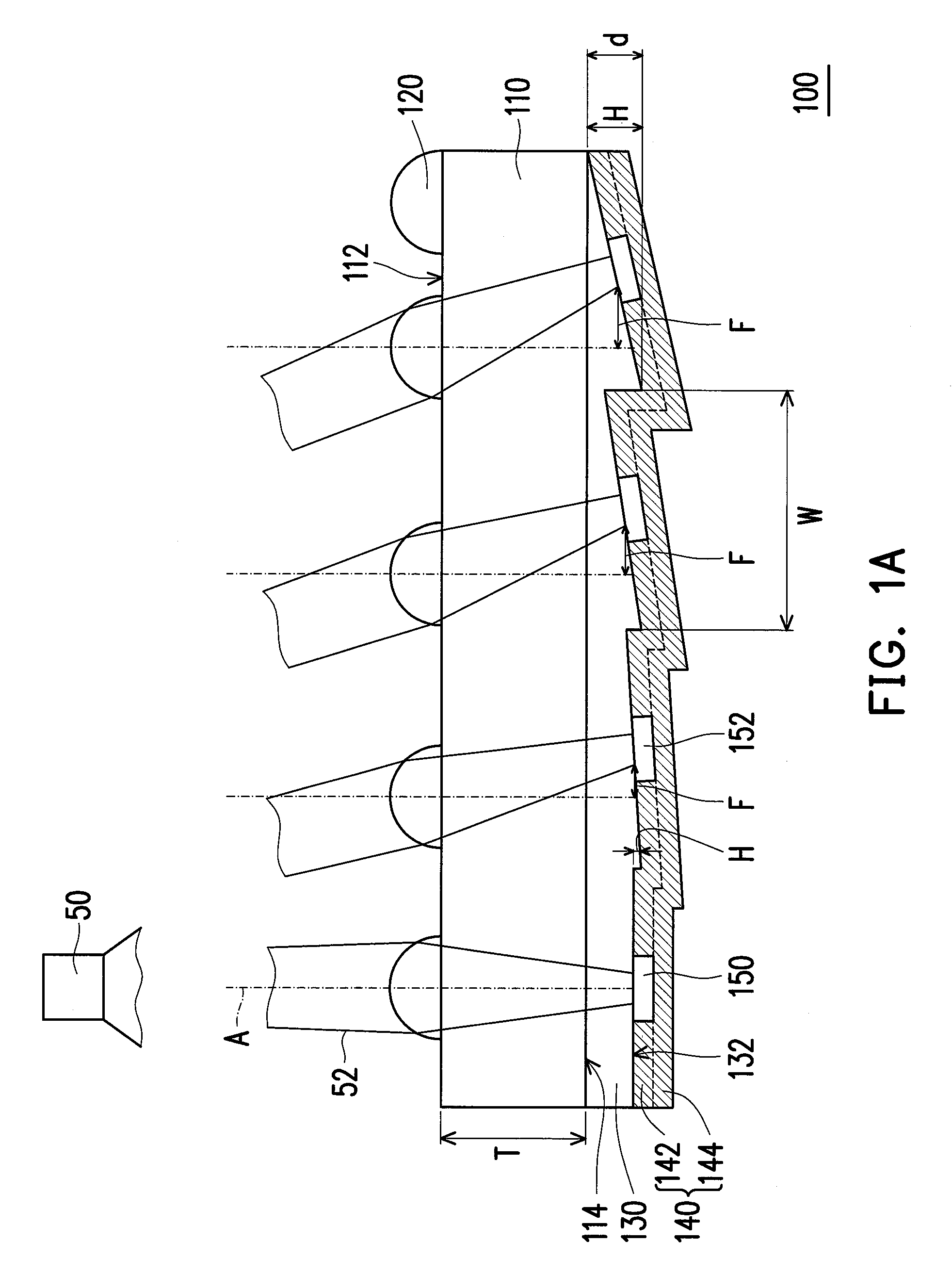

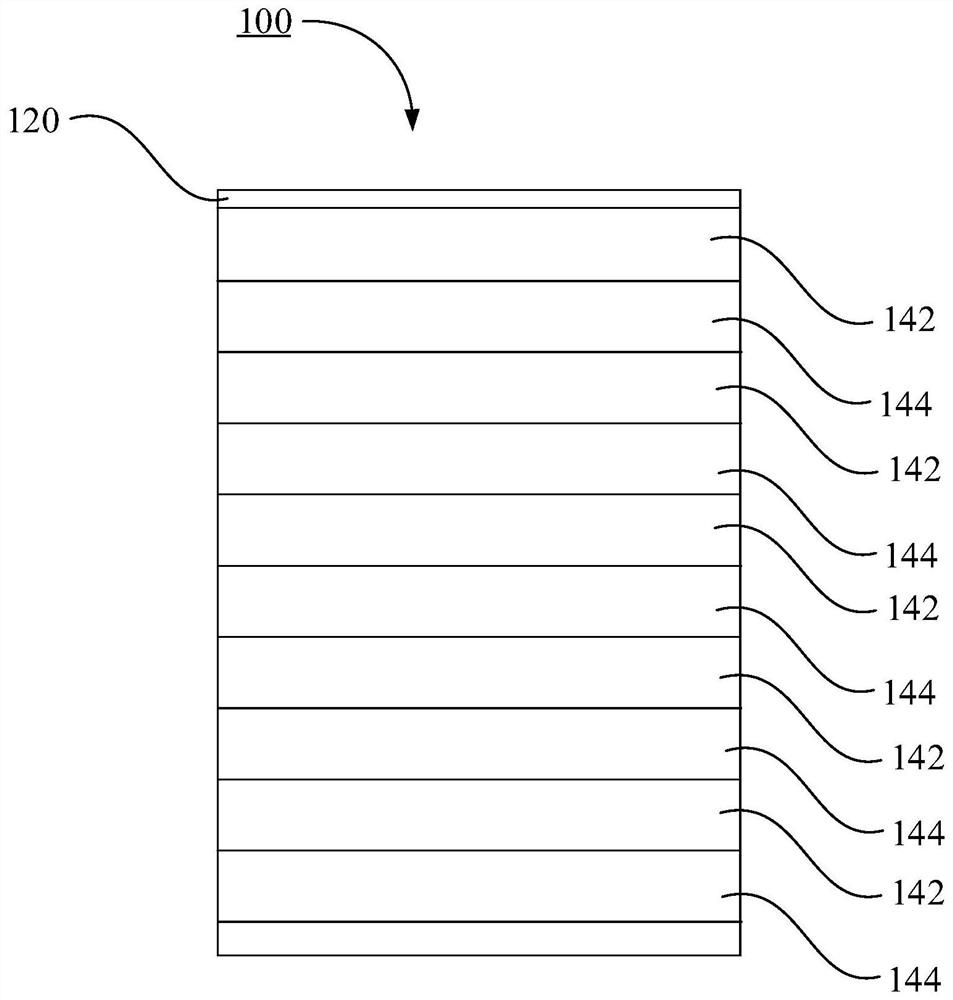

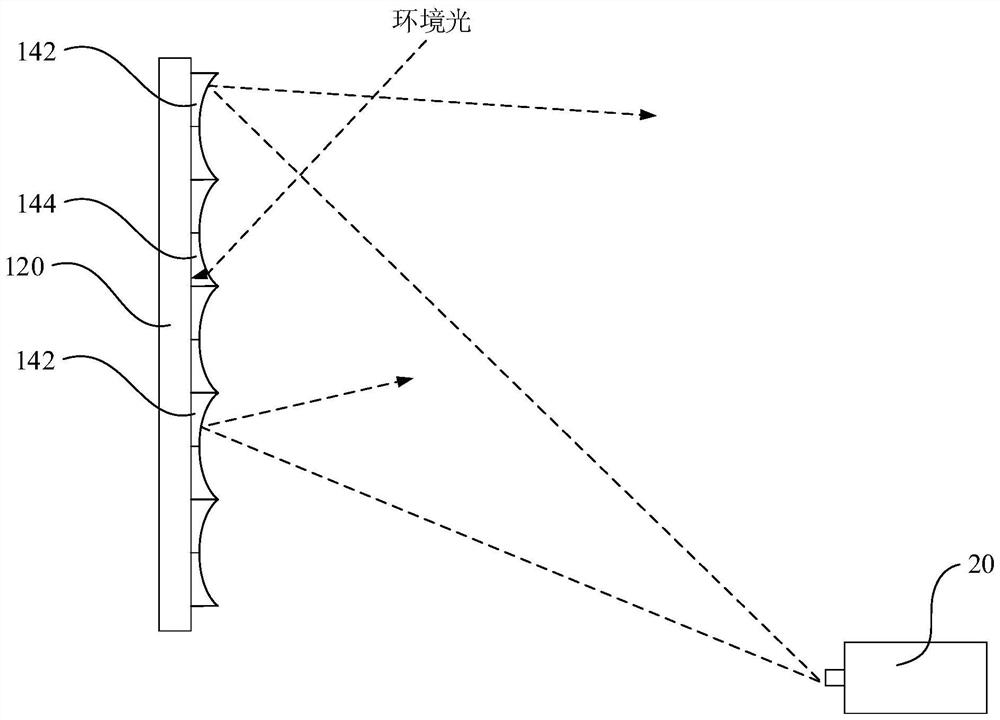

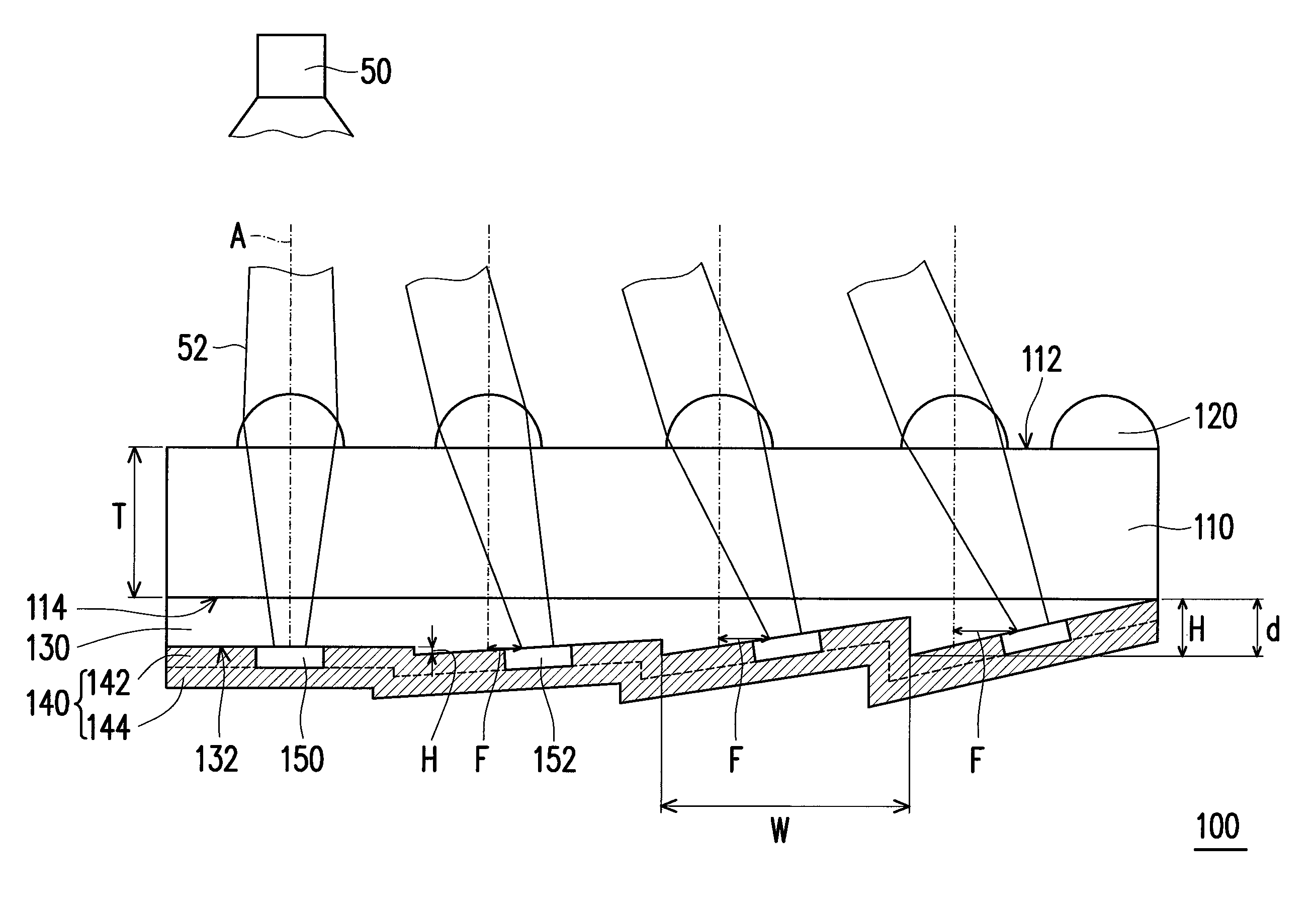

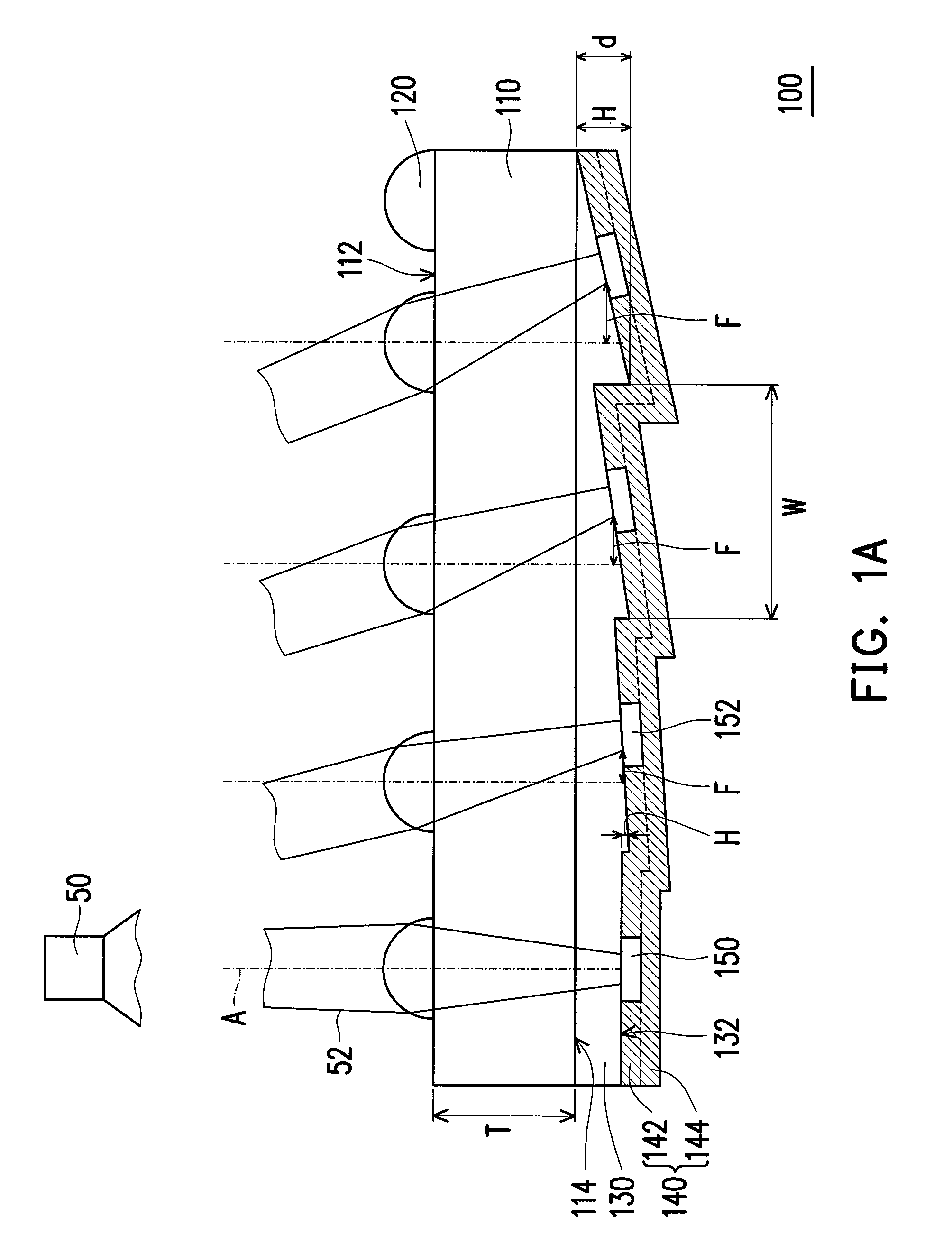

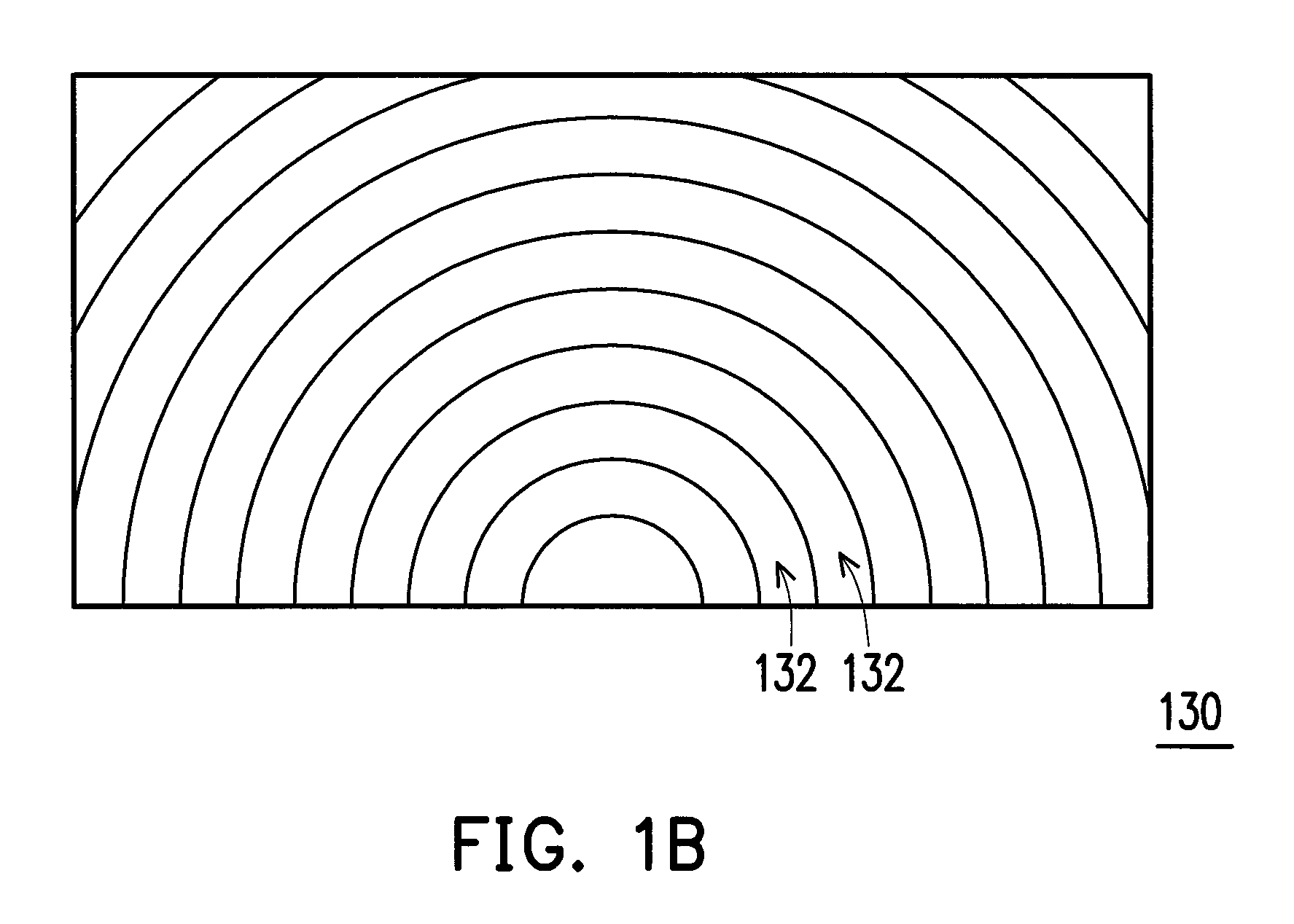

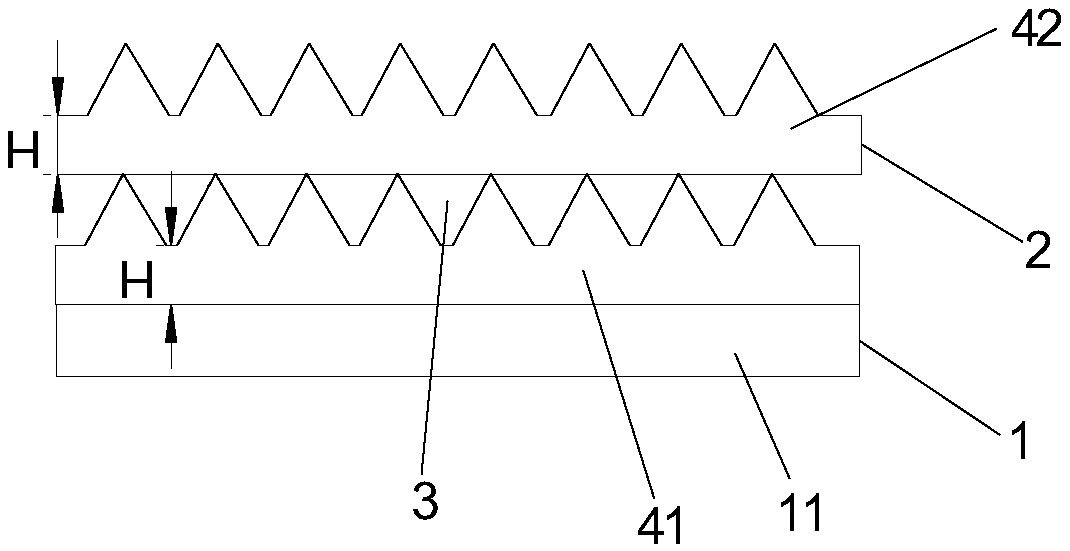

Projection screen and manufacturing method of projection screen

ActiveUS20150362832A1Improve image contrastHigh brightness gainMirrorsDiffusing elementsFresnel lensProjection screen

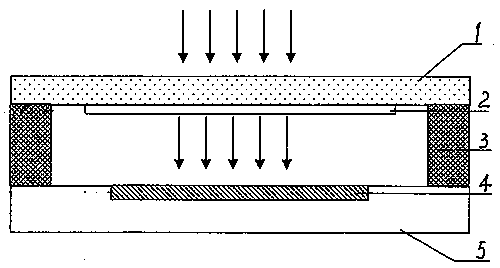

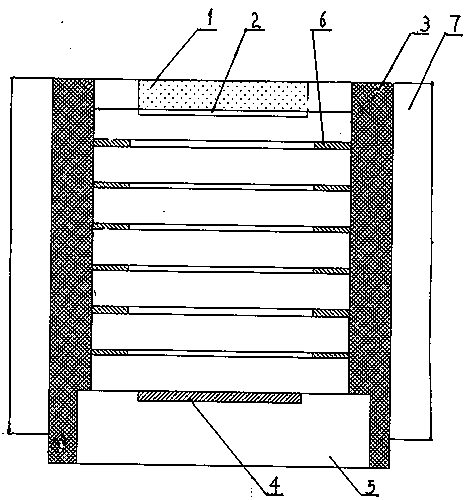

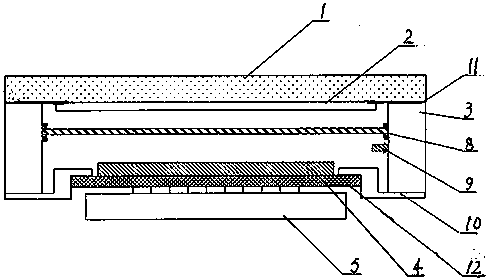

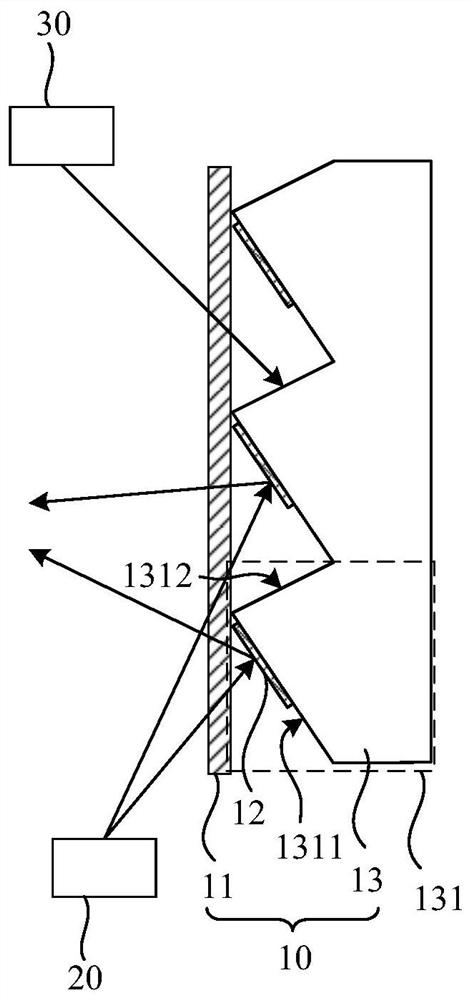

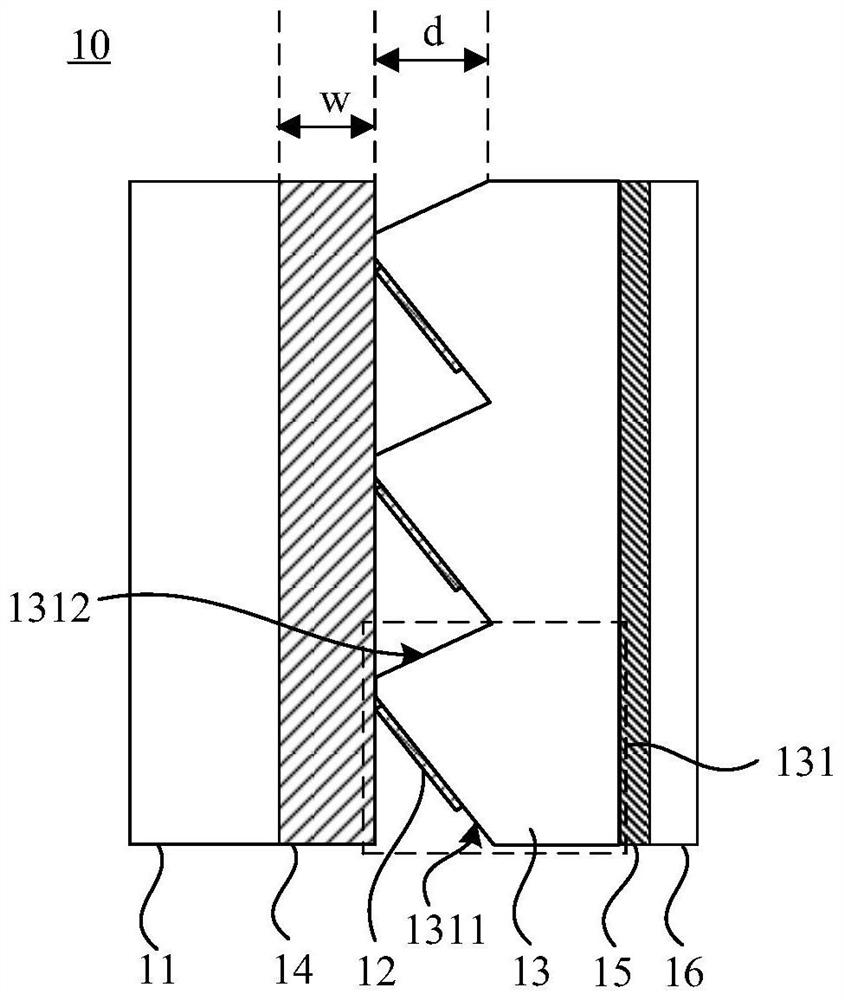

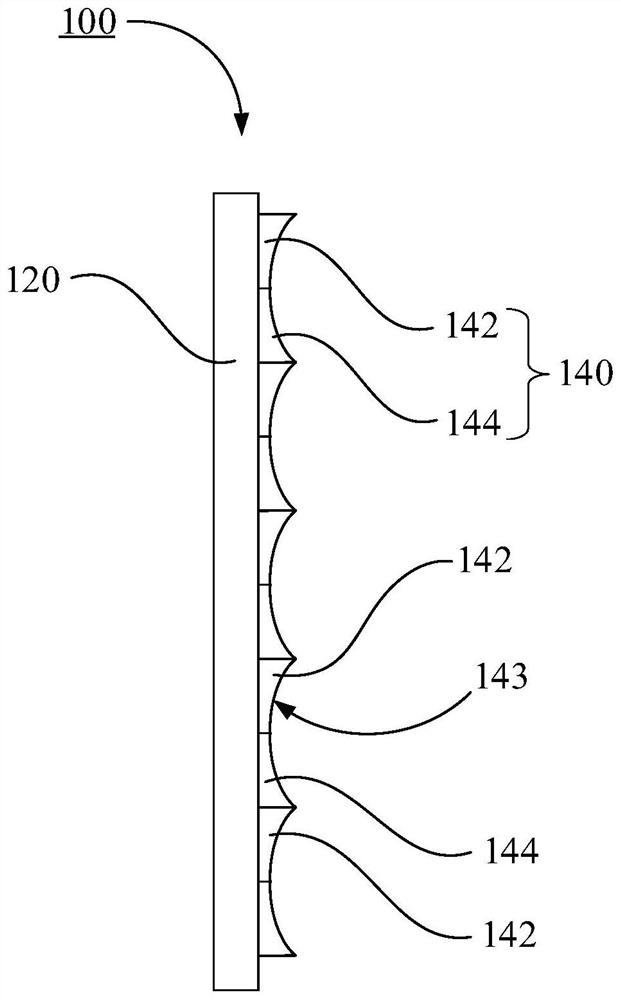

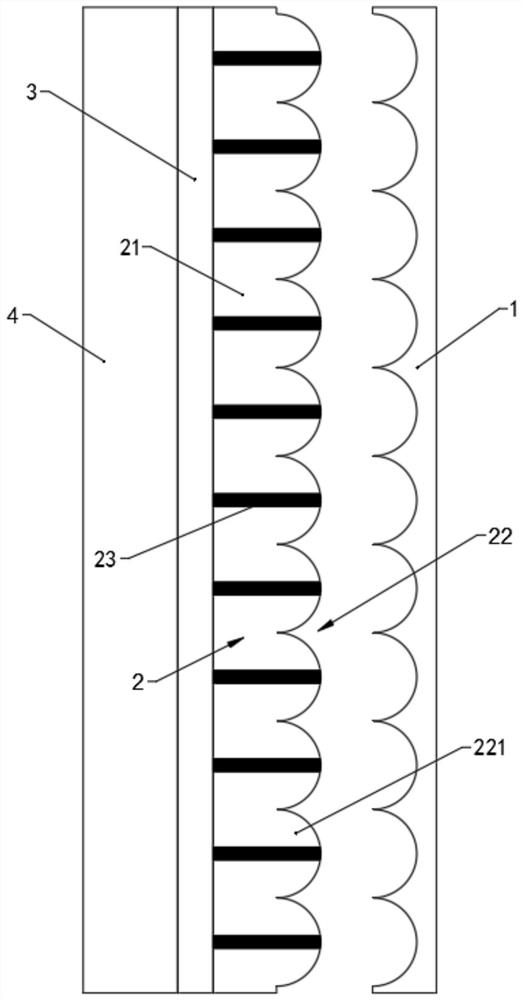

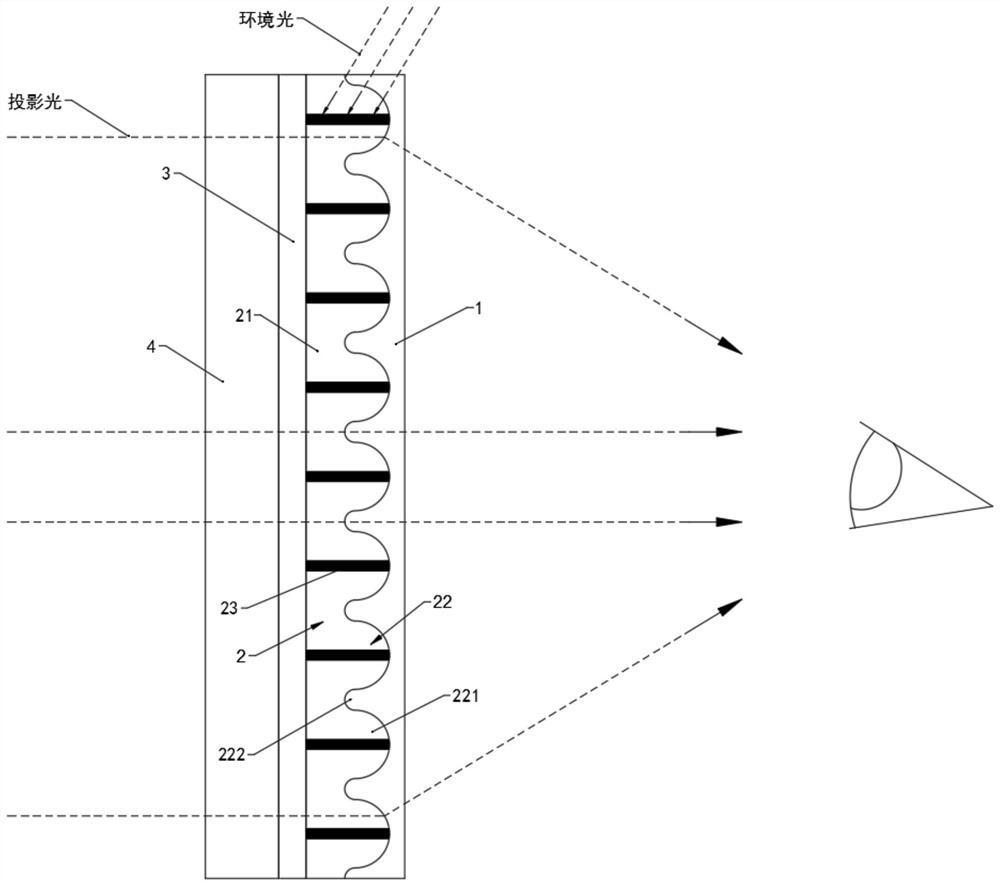

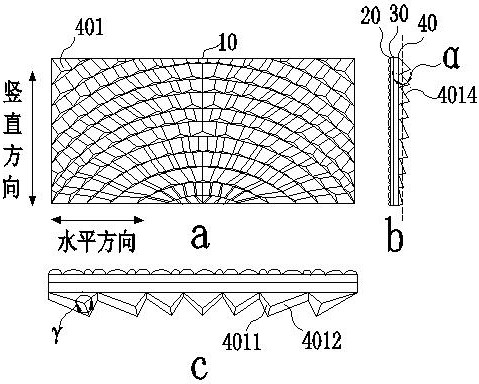

A projection screen that includes a transparent substrate, a plurality of micro-lens structures, a Fresnel lens structure, a light absorption layer, and a diffusive reflection layer is provided. The transparent substrate has a first surface and a second surface opposite to the first surface. The micro-lens structures are located at the first surface of the transparent substrate. The Fresnel lens structure is located at the second surface of the transparent substrate. The light absorption layer includes a light absorption portion. The diffusive reflection layer includes a plurality of dispersive diffusive reflection portions connected to the Fresnel lens structure. The deviation degrees of the diffusive reflection portions with respect to a plurality of optical axes of the corresponding micro-lens structures increase together with an increase in slopes of inclined surfaces of the Fresnel lens structure on the corresponding optical axes. A manufacturing method of the projection screen is also provided.

Owner:NANO PRECISION TAIWAN LTD

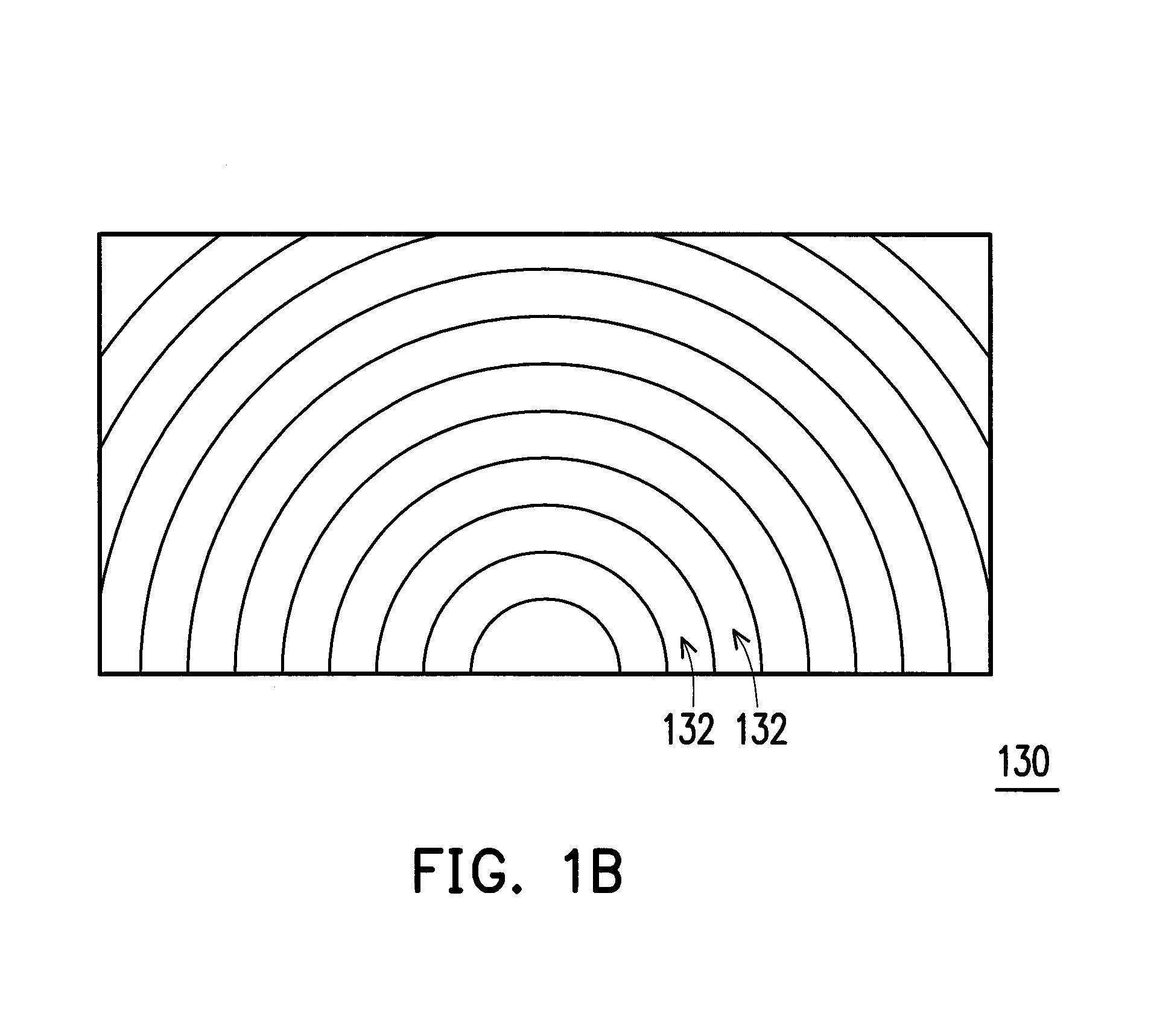

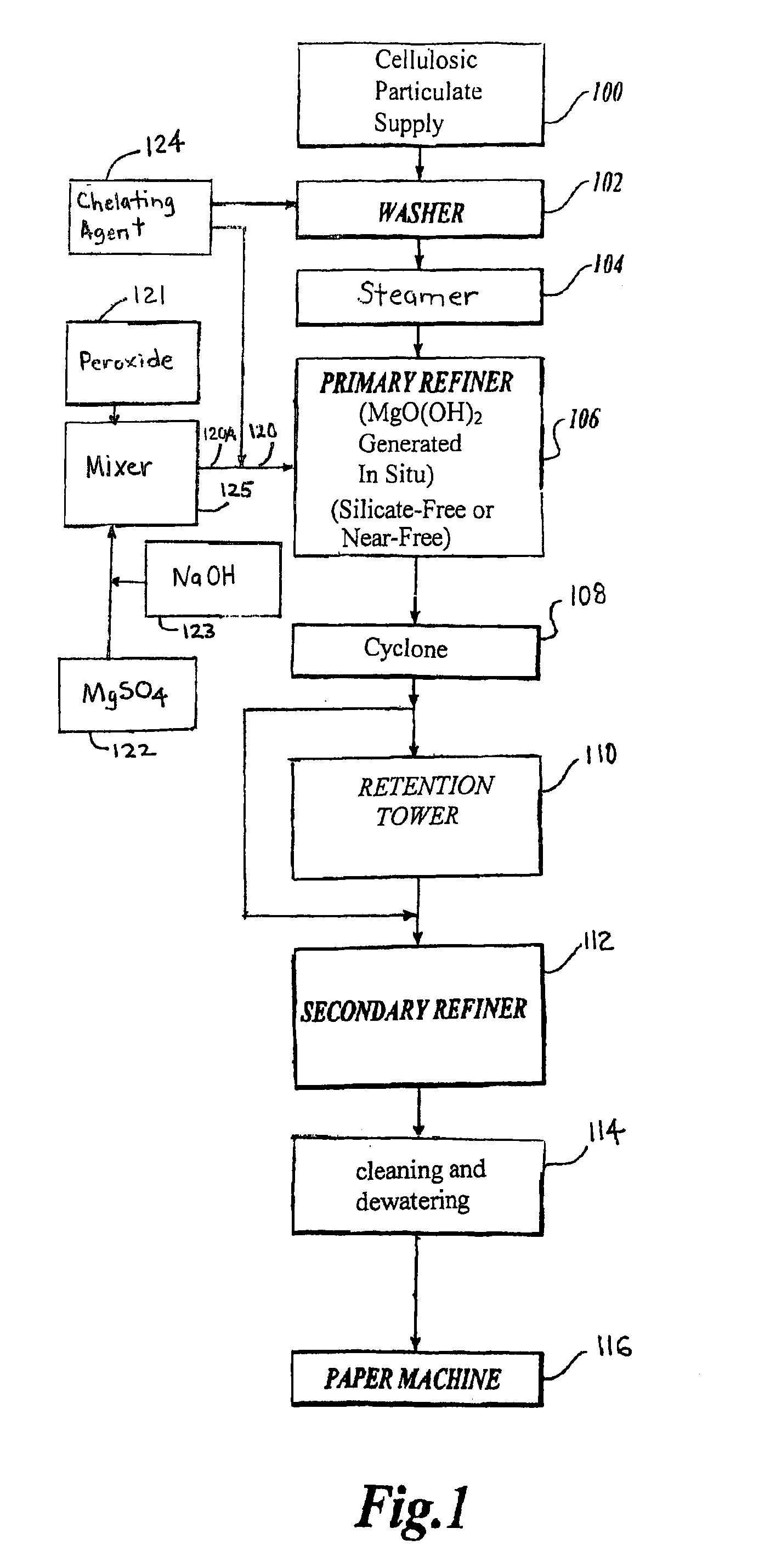

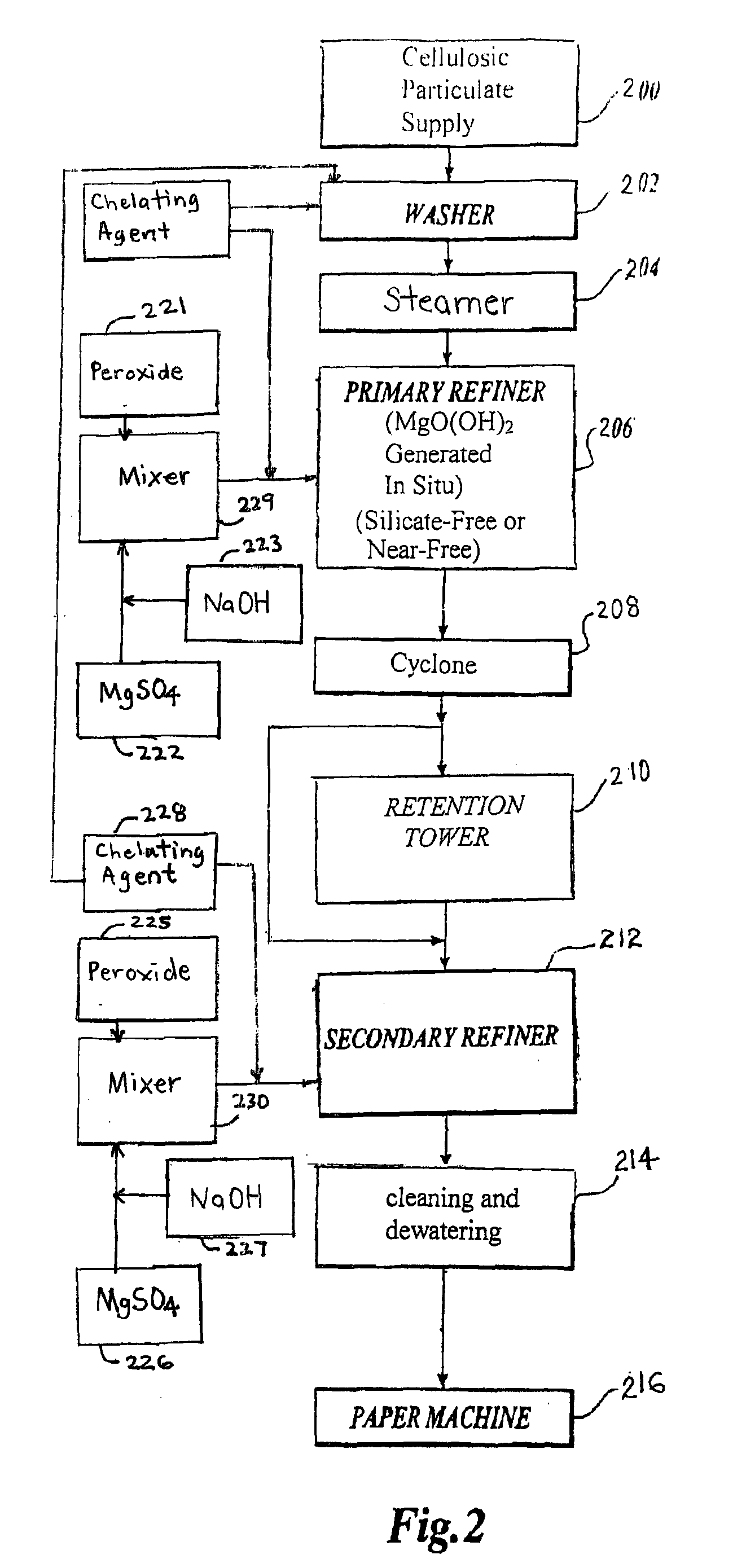

Silicate Free Refiner Bleaching

InactiveUS20130126109A1Prevent and reduce scale formationReduce scale formationPretreatment with water/steamOther chemical processesChemistryCellulose

A method for bleaching pulp includes introducing a bleaching liquor in at least one refiner to contact lignocellulosic particulates processed therein in the formation of pulp, wherein the bleaching liquor includes at least one peroxide, magnesium sulfate, caustic hydroxide, at least one chelating agent, and less than 0.1%, or less than 0.01%, or less than 0.001% by weight silicate based on dry weight of the lignocellulosic particulates. Magnesium perhydroxide is generated in situ in the refining system with bleaching of the particulates during refining and reduced scale occurs by use of the silicate or essentially silicate free conditions. A free or essentially silicate-free bleaching liquor which can provide highly brightened pulps also is described.

Owner:BUCKMAN LAB INT INC

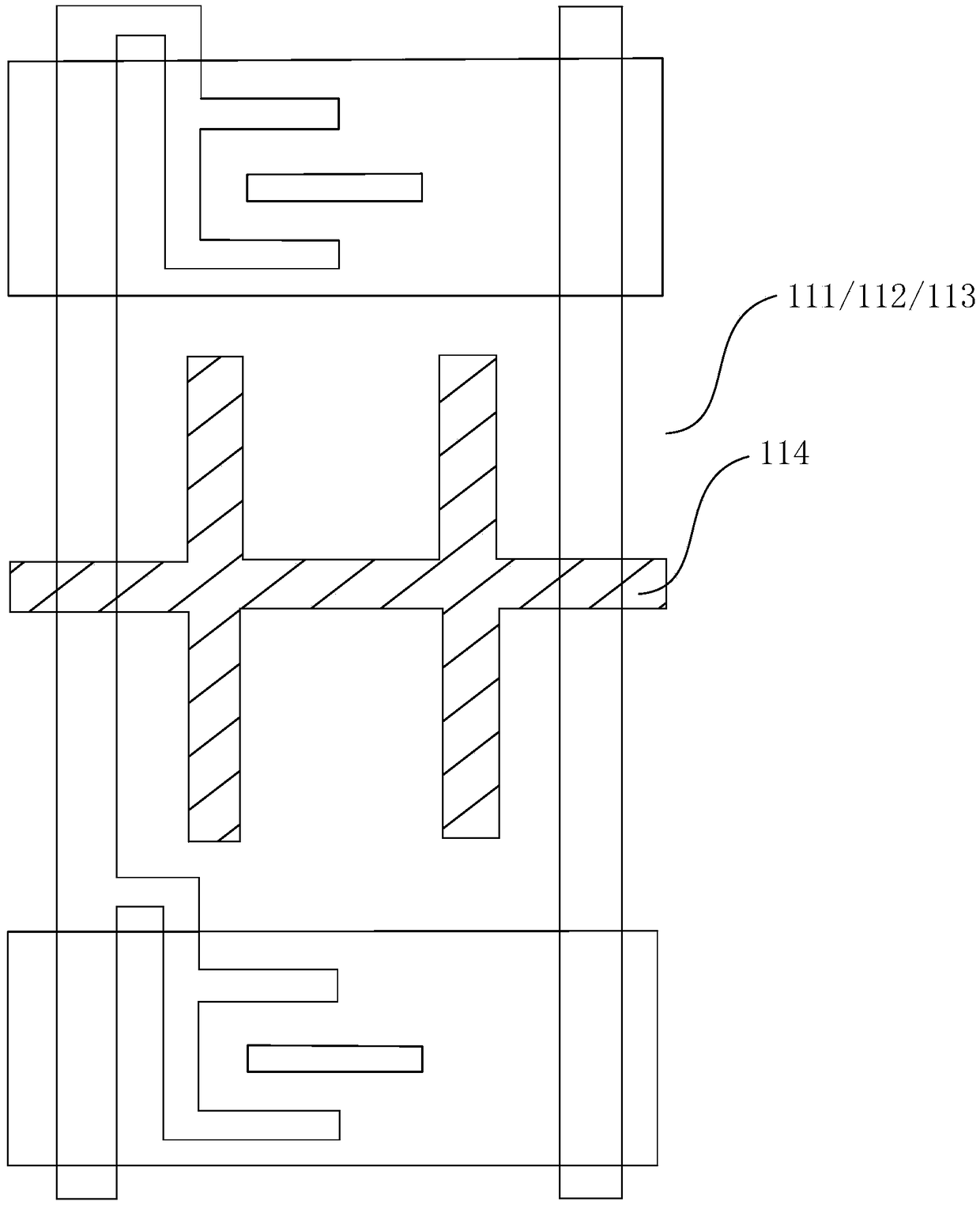

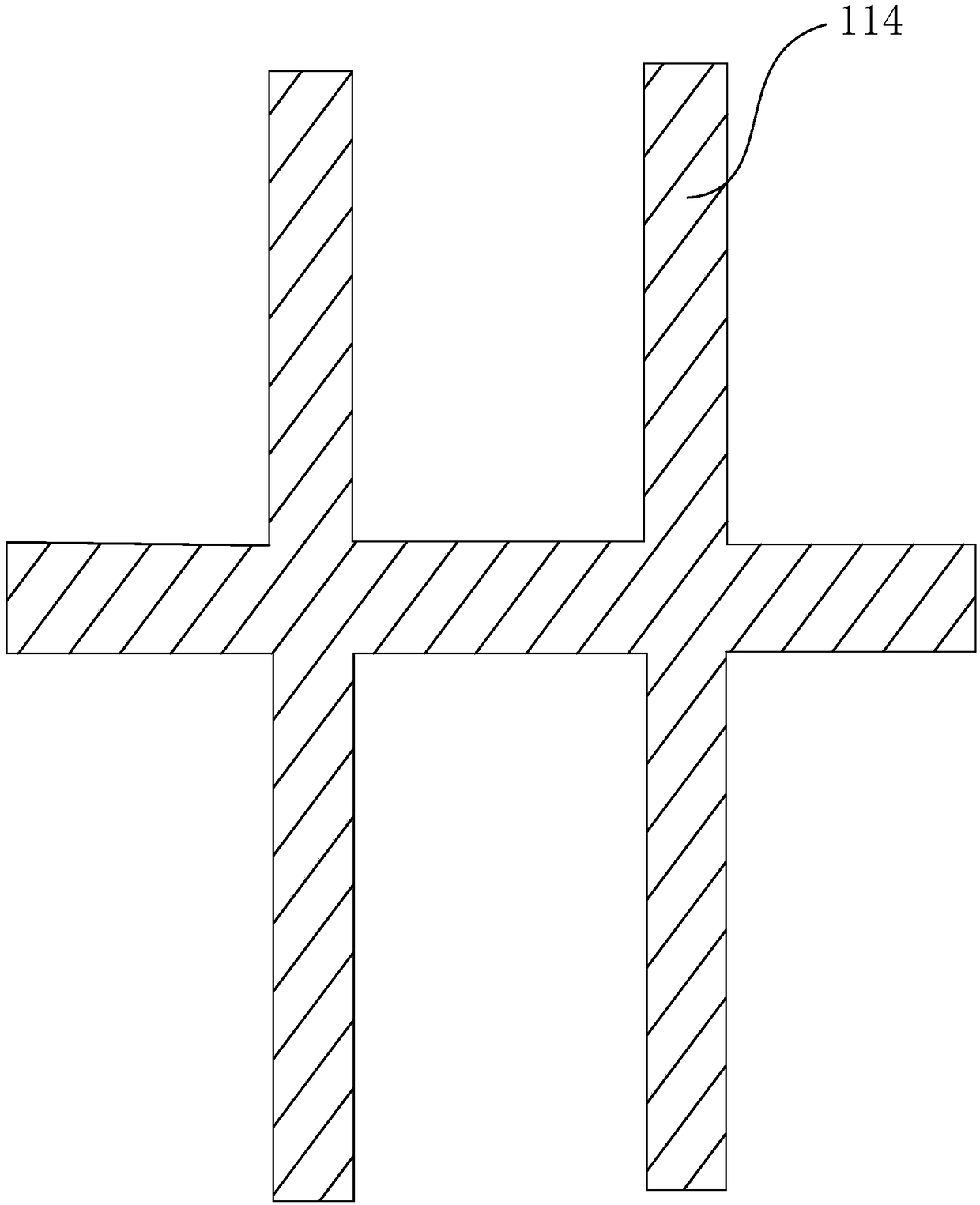

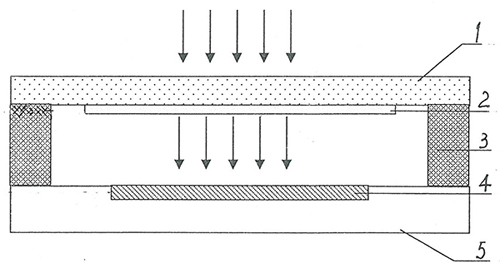

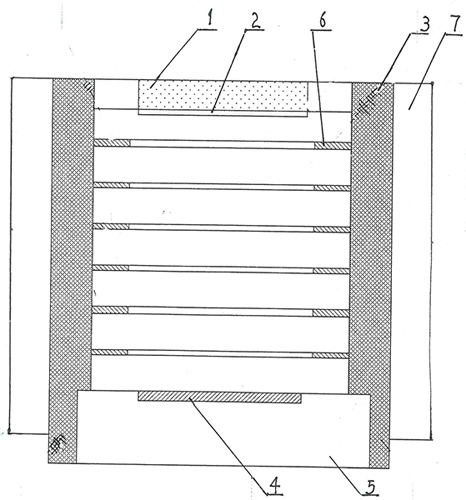

Display panel and display device

InactiveCN109491151AIncrease charging rateHigh brightness gainNon-linear opticsCapacitanceCharge rate

The invention discloses a display panel and a display device. The display panel comprises a first sub-pixel, a second sub-pixel and a third sub-pixel. Each of the first sub-pixel, the second sub-pixeland the third sub-pixel comprises a common line, a pixel electrode and a storage capacitor, wherein the pixel electrode is formed above the common line, and the storage capacitor is formed by an overlapped portion of the pixel electrode and the common line. The storage capacitor of the third sub-pixel is smaller than that of the first sub-pixel and the second sub-pixel, and the third sub-pixel corresponds to blue. The smaller the storage capacitor, the larger the corresponding sub-pixel charging rate. Since the storage capacitor of the third sub-pixel is smaller than that of the first sub-pixel and the second sub-pixel, the charging rate of the third sub-pixel is higher than that of the first sub-pixel and the second sub-pixel, luminance gain of the third sub-pixel is increased, and the problem of yellowish white light of the display panel is solved.

Owner:HKC CORP LTD

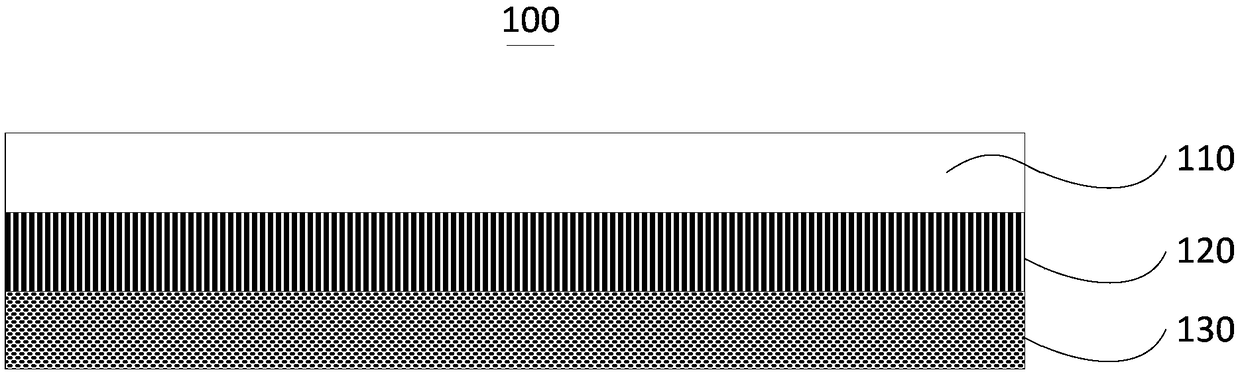

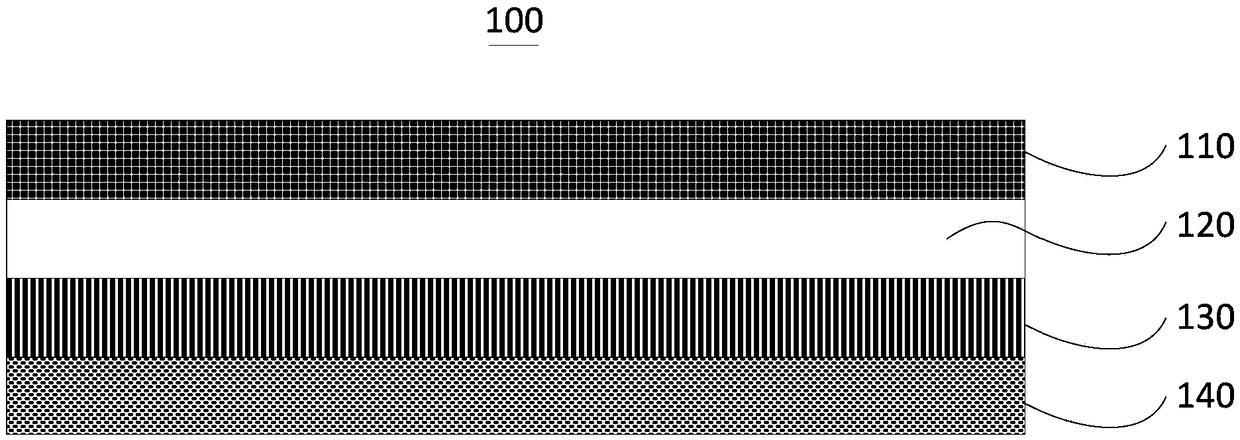

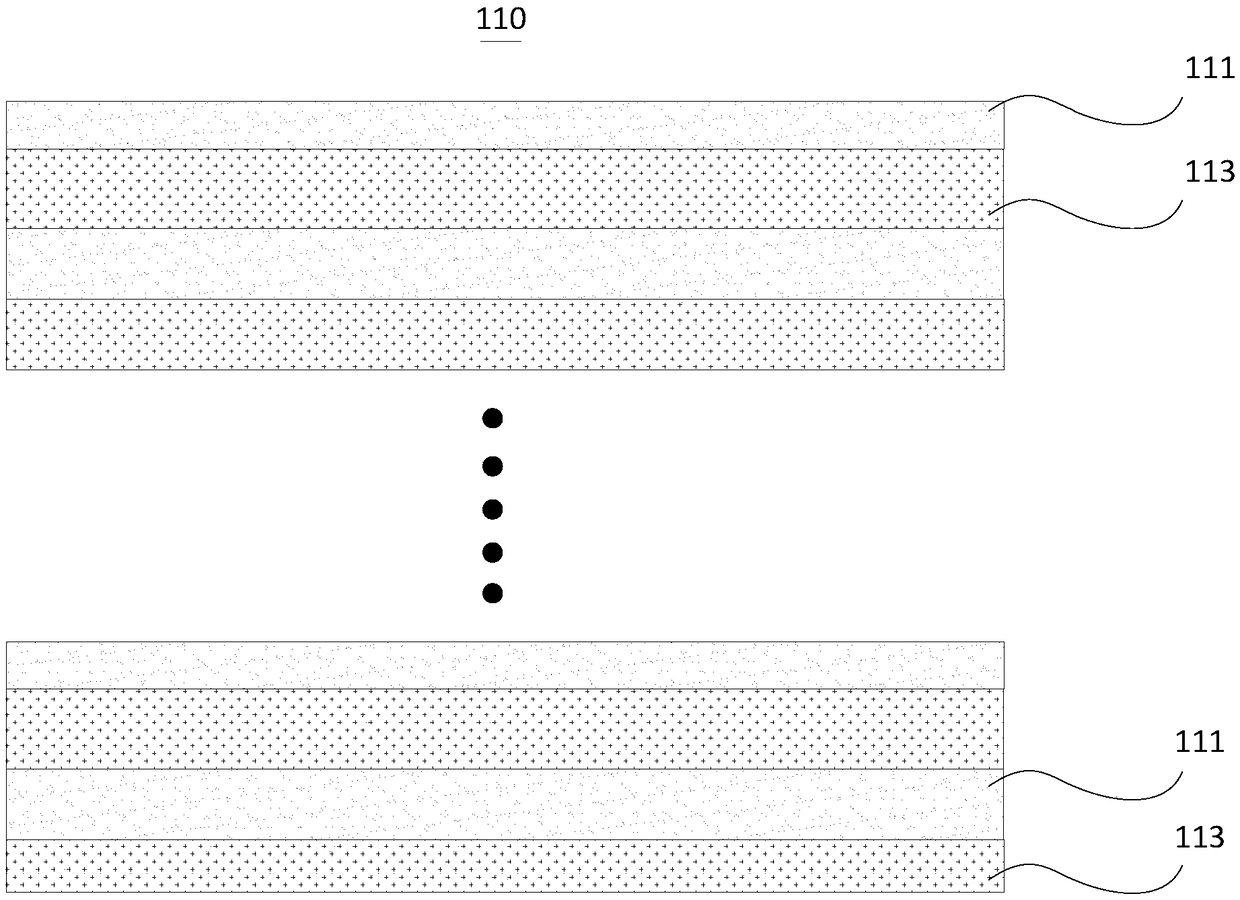

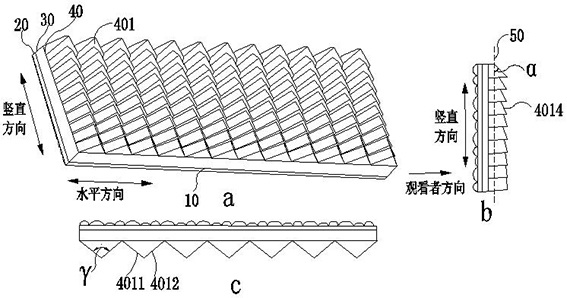

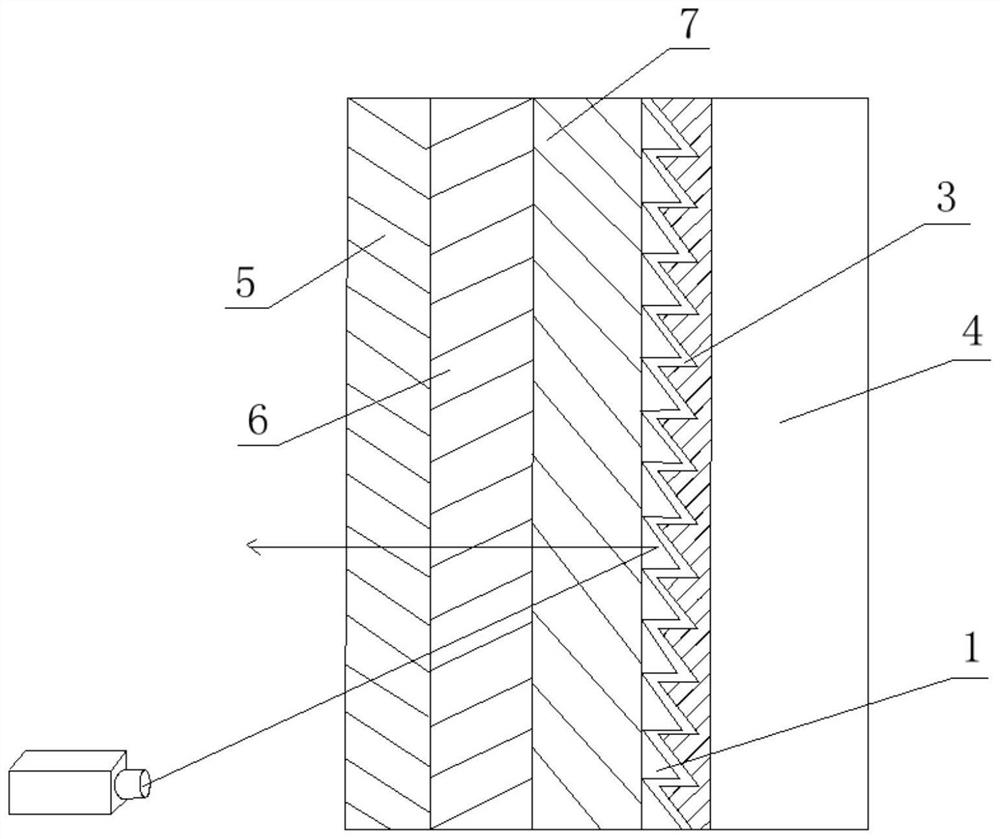

Optical thin film and preparation method thereof

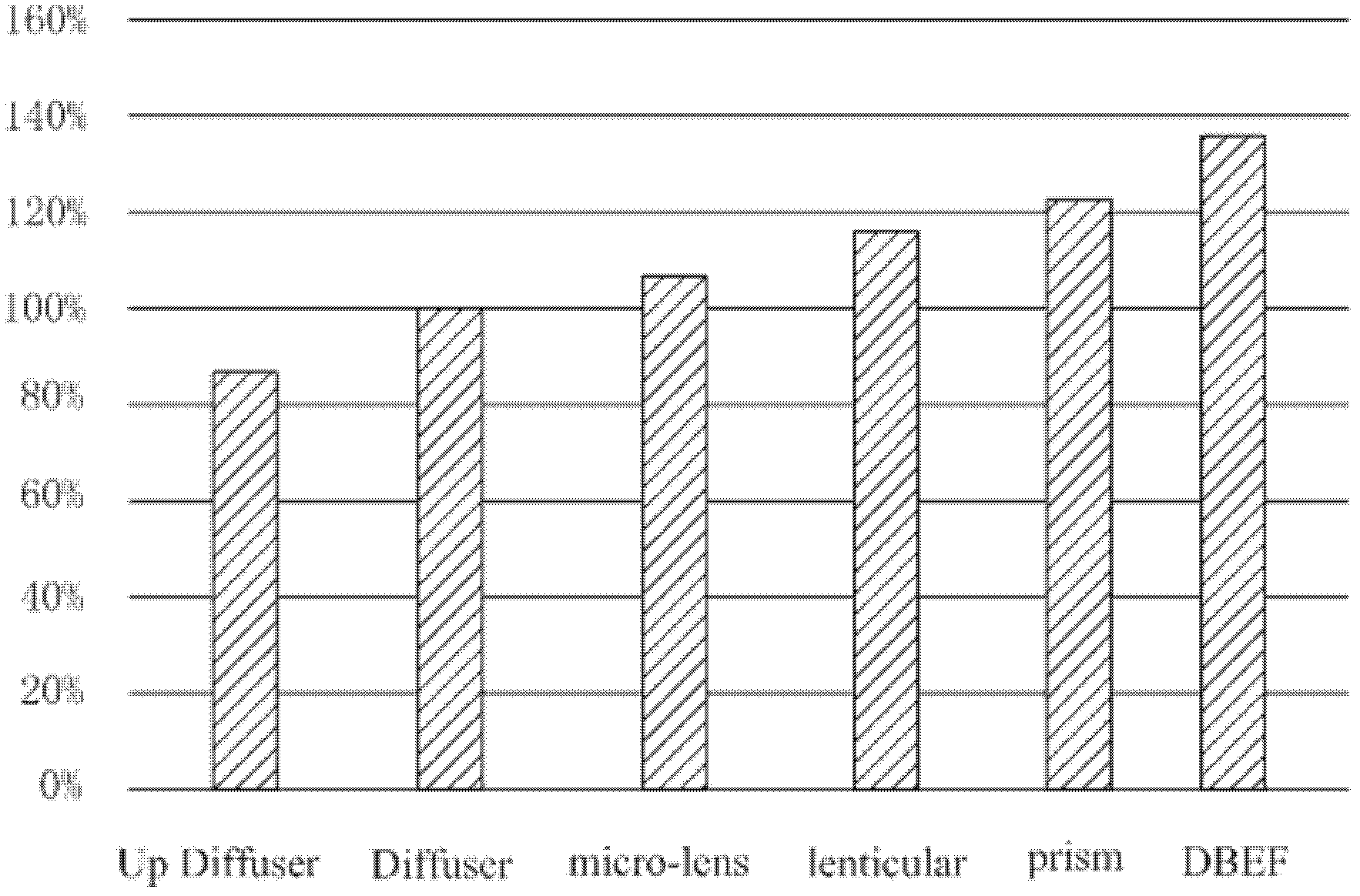

PendingCN108897081AIncrease brightnessAnti-peep angle effect is goodPrismsDiffusing elementsOptical thin filmProtection layer

The invention relates to the field of optical thin film, in particular to optical thin film and a preparation method thereof. In order to solve the problem that the luminance of existing peep-proof film is prone to decline, the invention provides the optical thin film and the preparation method thereof. The optical thin film comprises a light path alignment structural layer, a base film layer, a dodging diffusion layer, a light screening structural layer and a surface protection layer from bottom to top in sequence. The optical thin film has high luminance gaining and peep proofing effects atthe same time.

Owner:NINGBO EXCITON TECH

Miniaturized high-gain low-illuminance night-vision imaging device

ActiveCN109547718AMiniaturizationHigh brightness gainTelevision system detailsColor television detailsCMOSIlluminance

The invention discloses a miniaturized high-gain low-illuminance night-vision imaging device for similar night vision products for the military helmet night-vision device and related industry. The main technical scheme is as follows: a tube shell input end is hermetically sealed with an input window, a tube shell tail end is hermetically welded with an output end of a CMOS image sensor, a photoelectric cathode is plated in a surface effective area in the input window; a micro-channel plate is mounted between a second metal ring and a third metal ring of the tube shell; the CMOS image sensor iswelded with a ceramic substrate, and the output end of the CMOS image sensor is connected with a readout circuit board. A test result shows that the phenomenon that the original device is low in gainis overcome thoroughly, and the demands of effectively improving the device gain, realizing the miniaturization and being suitable for the military helmet night-vision device and like night-vision product for single use are reached.

Owner:NORTH NIGHT VISION TECH

Projection screens and projection systems

PendingCN109031879AIncrease contrastHigh color reproductionProjectorsProjection screenRefractive index

The invention provides a projection screen and a projection system, which relate to the technical field of projection. Wherein the projection screen comprises a substrate layer; An imaging layer formed on one side of the substrate layer; A light-reflecting film lay is formed on a side of that image layer remote from the substrate layer. The reflective film layer includes a first film layer and a second film layer having a different refractive index from the first film layer so that the reflective film layer is capable of reflecting light of red, green, and blue colors and absorbing light of other colors than red, green, and blue colors. With the above-mentioned setting, the problem that the imaging effect of the existing projection screen is poor can be overcome.

Owner:CHENGDU FSCREEN SCI TECH

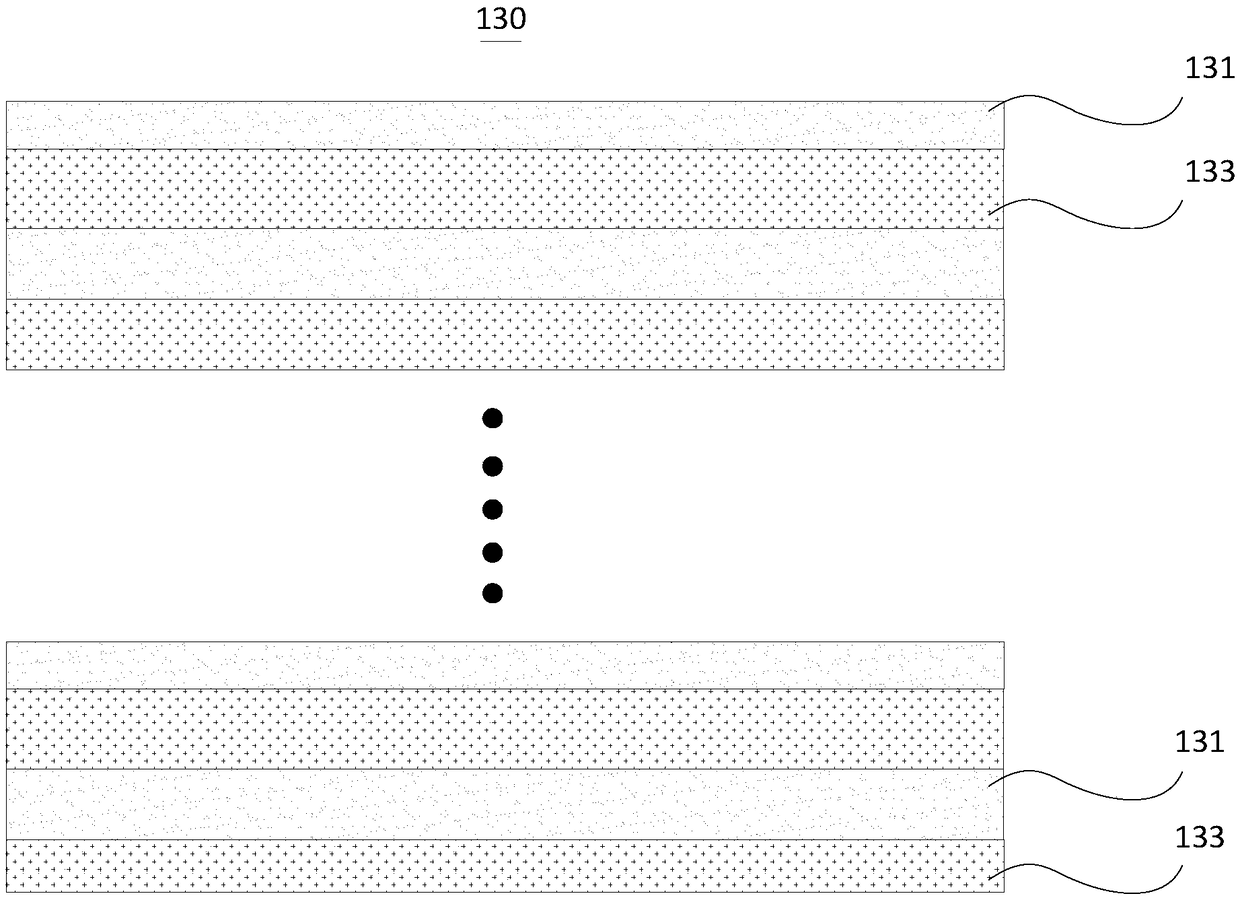

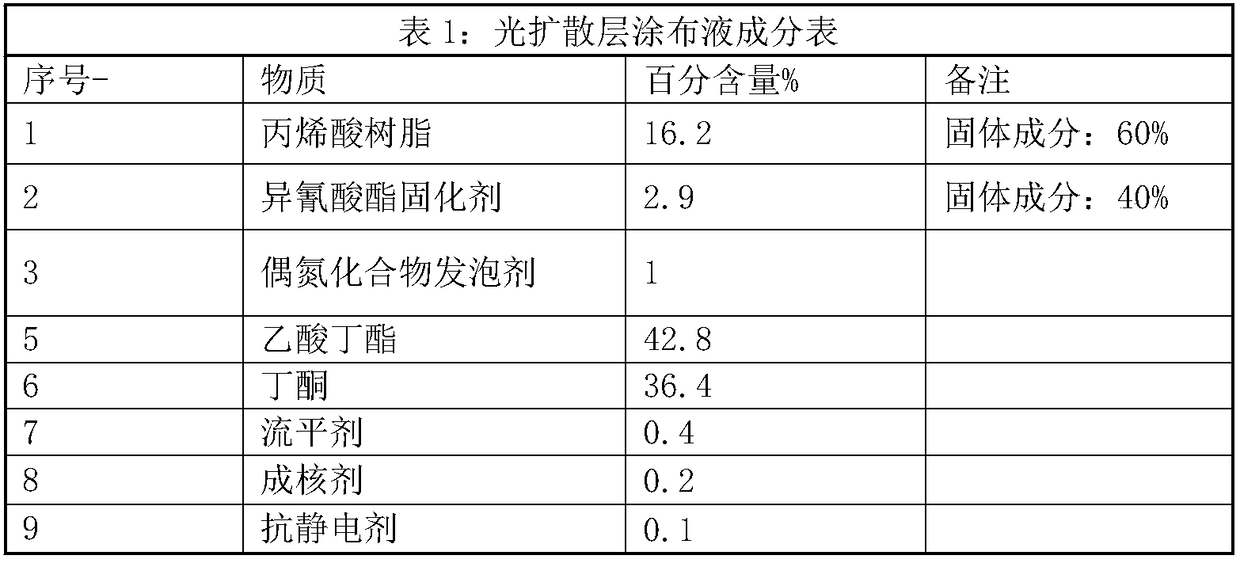

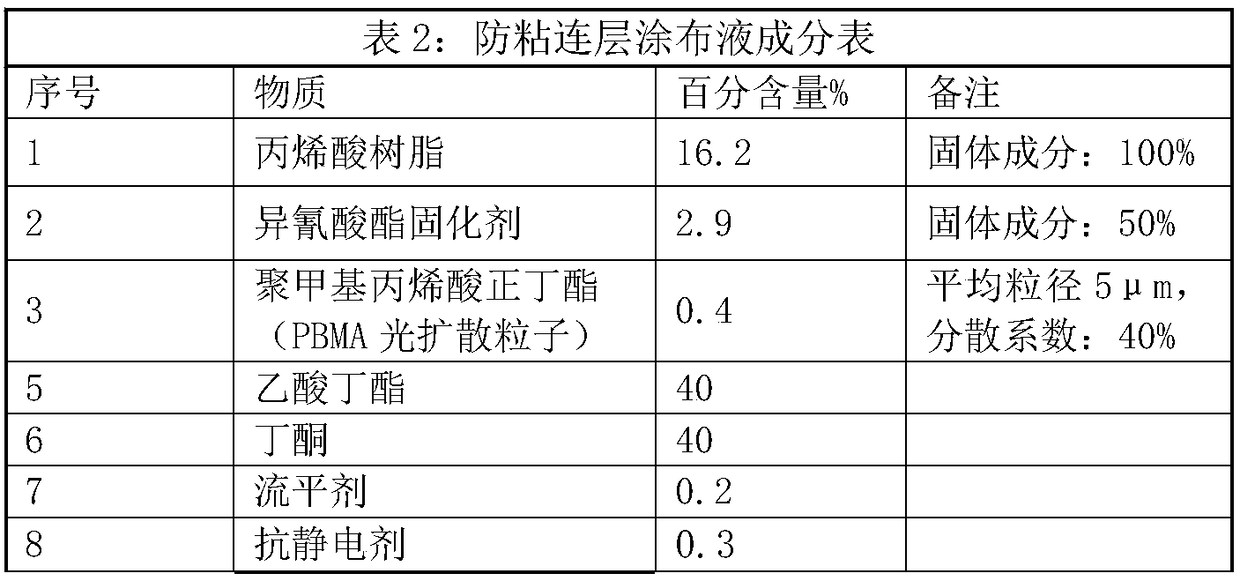

High-luminance optical diffusion film

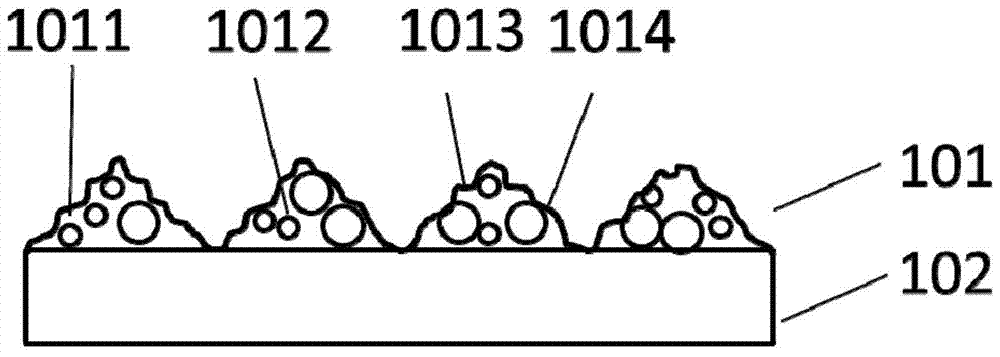

ActiveCN109471212AIncrease brightnessHigh brightness gainDiffusing elementsOptoelectronicsHigh luminance

The invention relates to an optical diffusion film, in particular to a high-luminance optical diffusion film. The problem of low brightness gain of an existing diffusion film is solved. The high-luminance optical diffusion film is simple in structure and convenient to manufacture. The high-luminance optical diffusion film comprises a base material, an optical diffusion layer and an anti-adhesion layer. The anti-adhesion layer contains air bubbles. The high-luminance optical diffusion film has high brightness gain and high brightness.

Owner:NINGBO EXCITON TECH

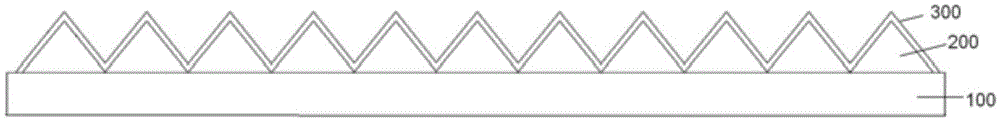

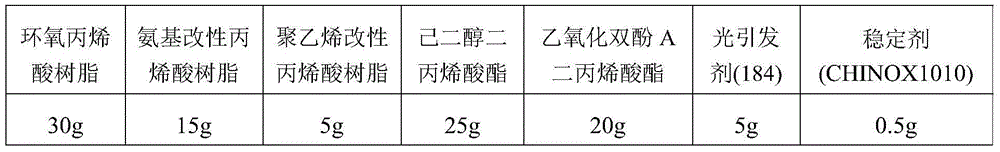

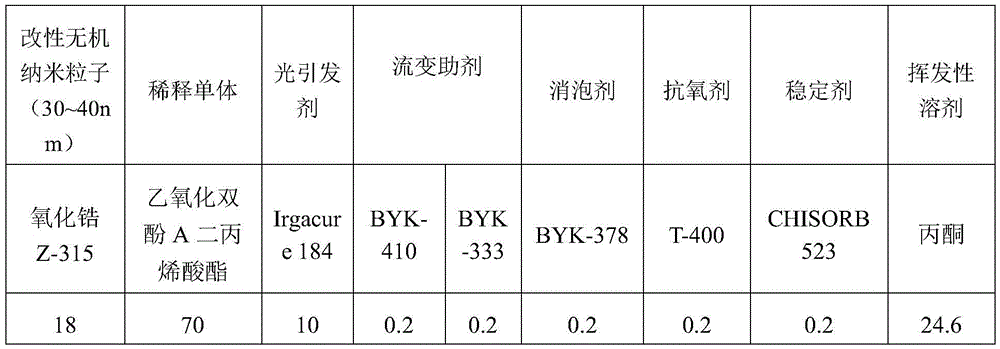

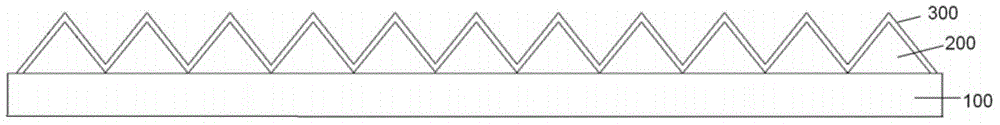

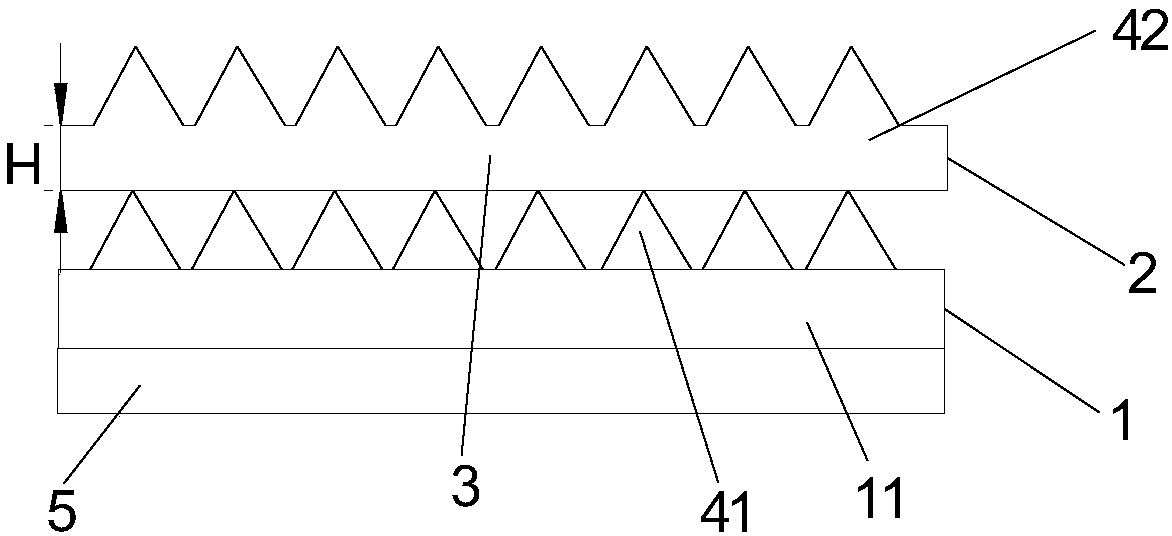

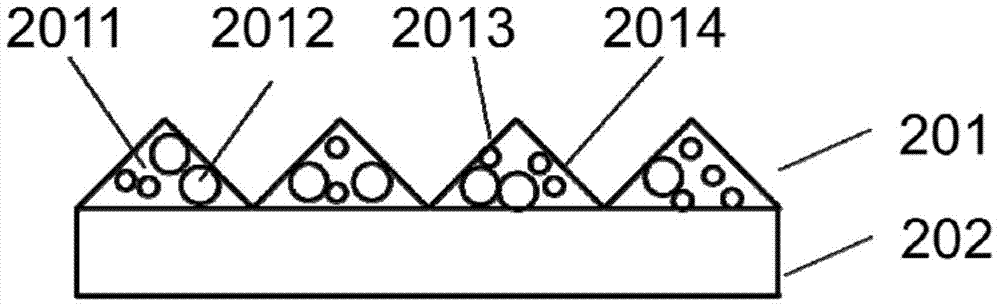

Brightening film and preparation method thereof

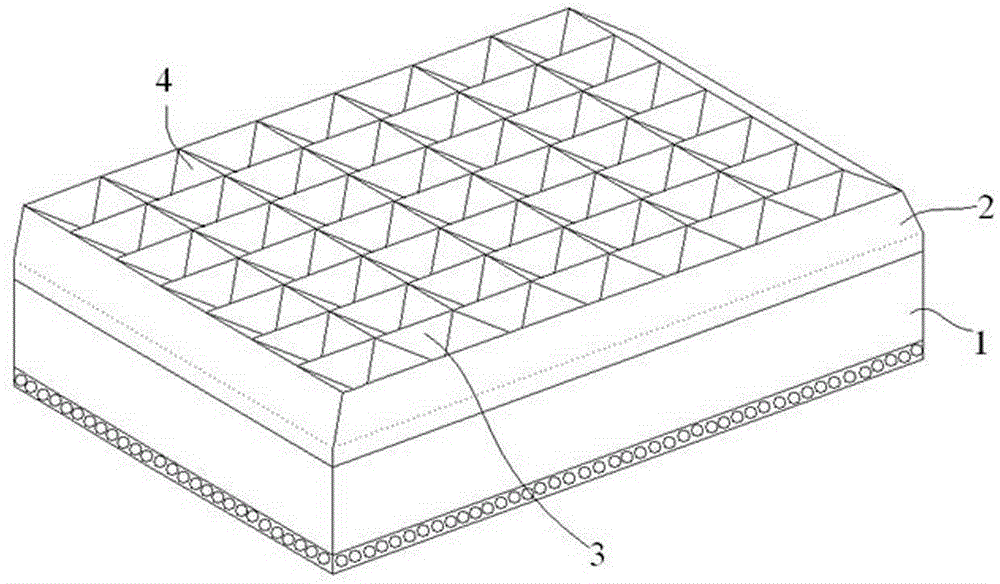

The invention provides a brightening film and a preparation method thereof. The brightening film comprises a base material, a light condensing layer and a refraction layer. The light condensing layer is arranged on the upper surface of the base material and composed of a plurality of light condensing structures. Each light condensing structure comprises a bottom face making contact with the upper surface of the base material. The upper surface of the light condensing layer is of a concave-convex structure. The refraction layer is arranged on the upper surface of the light condensing layer. A concave-convex structure matched with the concave-convex structure of the upper surface of the light condensing layer is arranged on the upper surface of the refraction layer. The refraction layer is prepared from an inorganic nanometer particle composition and volatile solvent. The inorganic nanometer particle composition is prepared from inorganic nanometer particles, first attenuation monomer, first photoinitiator and first surface auxiliaries. In the brightening film, an inorganic nanometer particle layer is attached to the upper surface of the light condensing layer independently to be used as the refraction layer, the phenomenon that because inorganic nanometer particles are added to a light-cured resin composition, components are incompatible can be avoided, and the brightening film can have a high refractive index and brightness gain.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

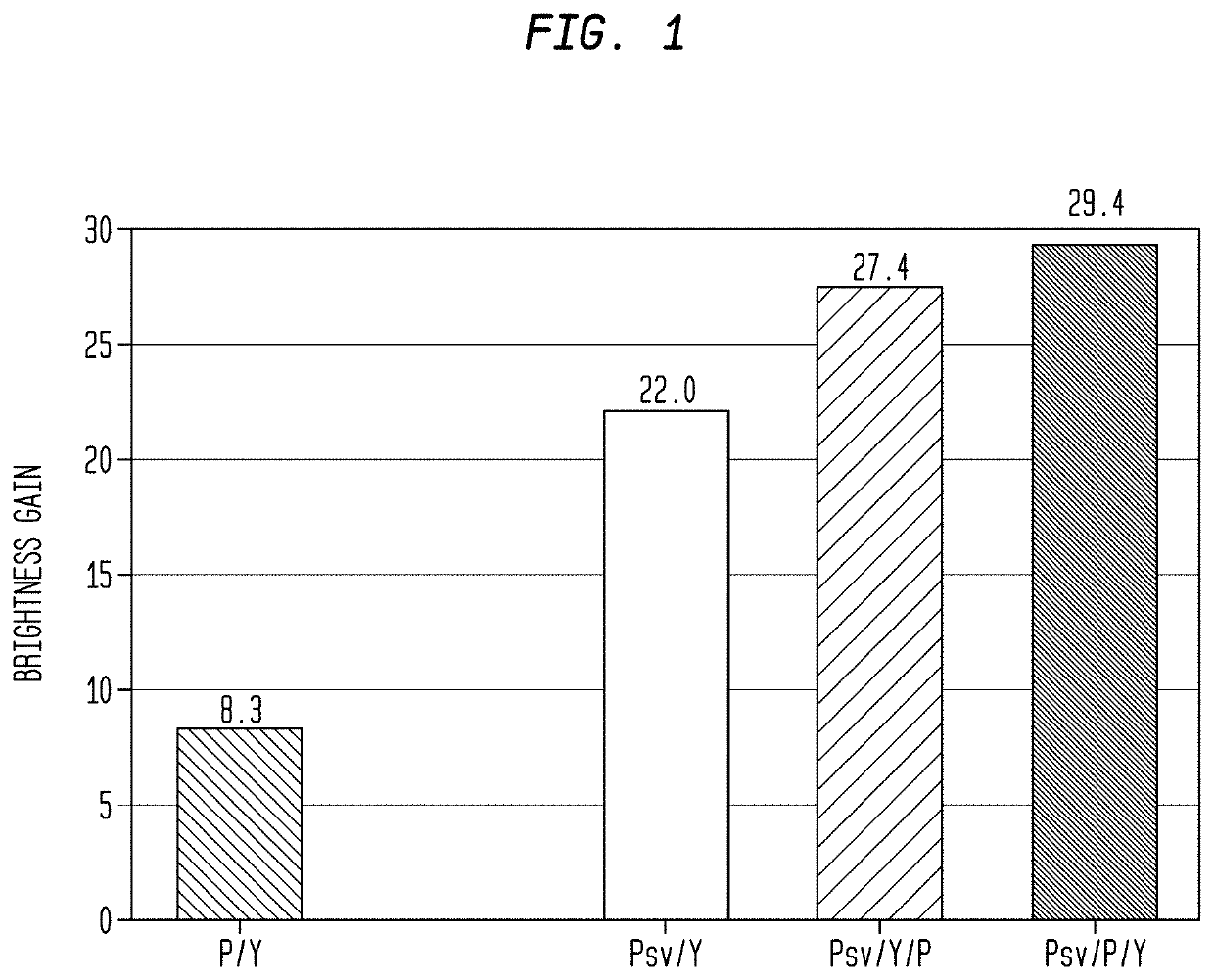

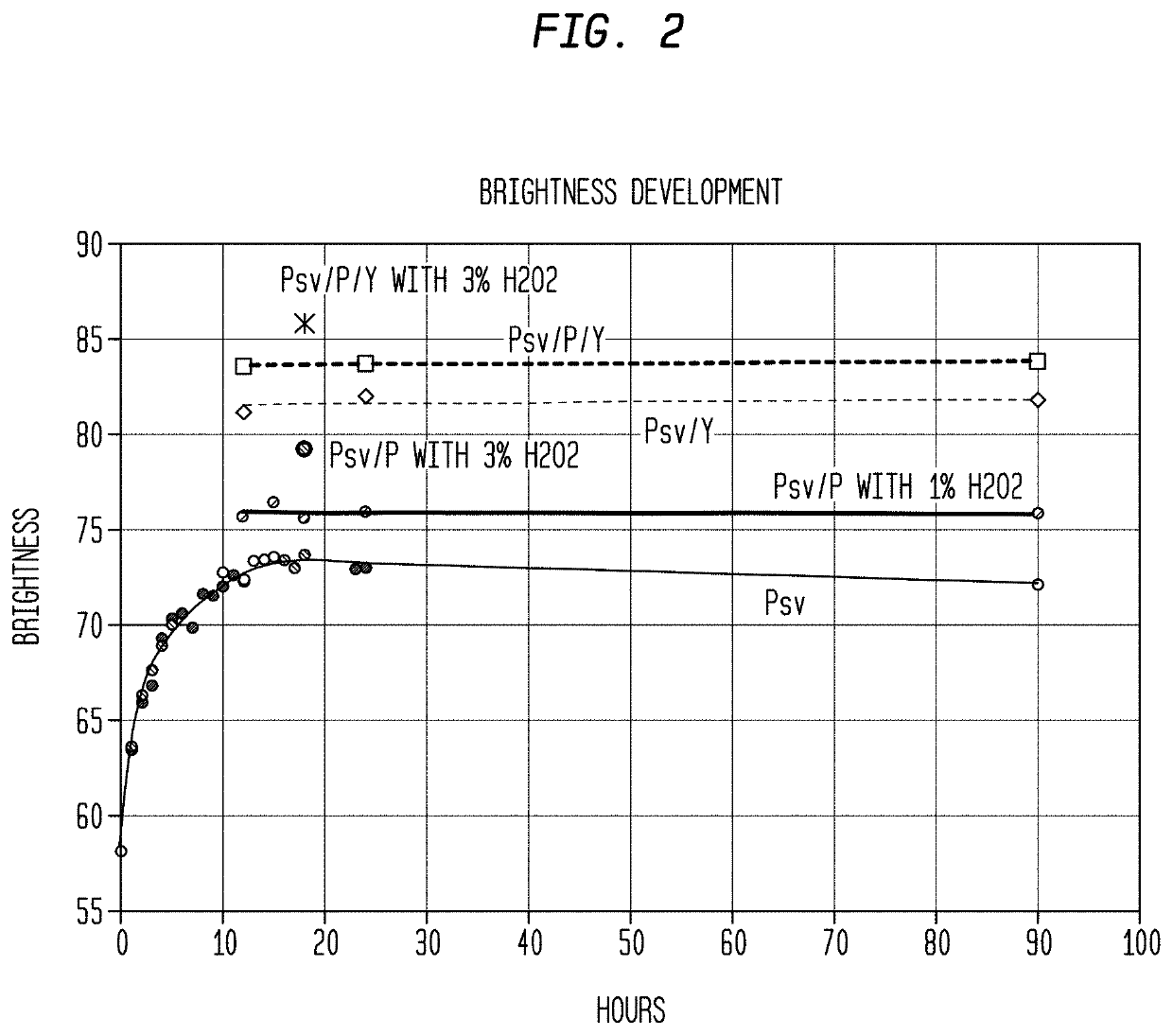

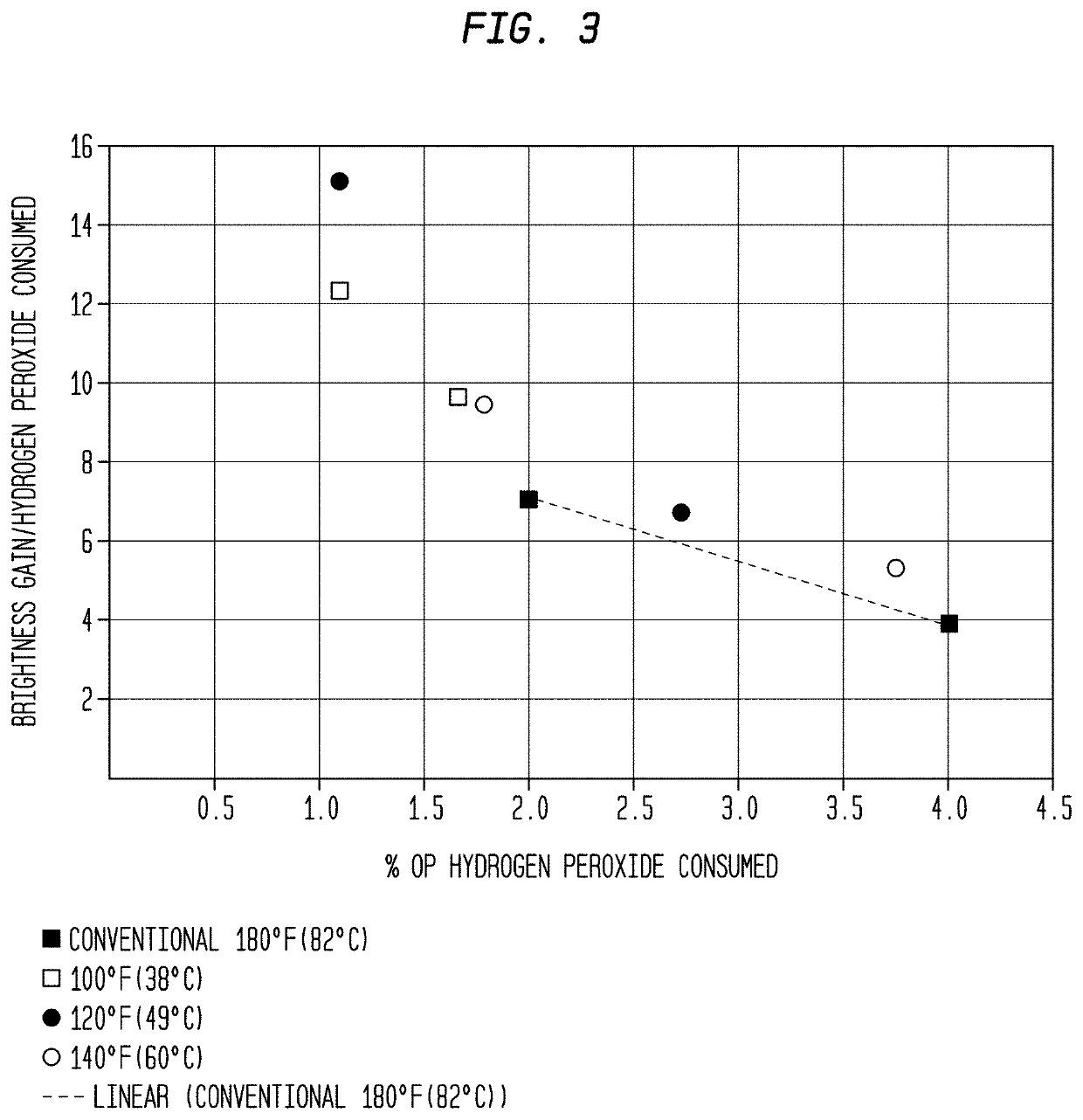

High Efficiency Fiber Bleaching Process

ActiveUS20210079594A1High brightness gainLow costPulp bleachingSecondary cellulose fibresCelluloseFiber

A high efficiency bleaching method for cellulosic pulp includes: (a) providing a charge of aqueous cellulosic pulp to a bleaching vessel at a consistency of from 10% to 30% along with a peroxy bleaching agent and an alkaline agent effective to adjust pH of the charge to 9.5 to 12.5; and (b) bleaching the aqueous cellulosic pulp in the bleaching vessel while maintaining a bleaching temperature of from 110° F. (43° C.) to 135° F. (57° C.) and a pH of the charge from 9.5 to 12.5 for an extended bleaching retention time. The bleaching method is advantageously used to bleach low brightness recycle pulp, and / or as part of a multistage process with bleaching stages of lesser duration, and / or as a high peroxy efficiency, low dose bleaching process or in connection with concurrently storing and bleaching pulp.

Owner:GPCP IP HLDG LLC

Brightness enhancement film, preparation method therefor, and optical composite film

The invention provides a brightness enhancement film, a preparation method therefor, and an optical composite film. The brightness enhancement film sequentially comprises a base material, a condensation layer and a refraction layer from the bottom to the top, wherein the condensation layer consists of a plurality of condensation structures. The condensation structures are respectively provided with a bottom surface which contacts with the upper surface of the base material. The refractive index of the refraction layer is greater than the refractive index of the condensation layer, and the upper surface of the refraction layer is provided with a concave-convex structure which is matched with a concave-convex structure on the upper surface of the condensation layer. In the above brightness enhancement film, the upper surface of the condensation layer is provided with a refraction layer with relatively high refractive index in an attaching manner. The upper surface of the refraction layer is enabled to be provided with the concave-convex structure matched with the concave-convex structure on the upper surface of the condensation layer, thereby equivalently enabling the surface of the brightness enhancement film to maintaining the geometrical shapes of the condensation structures. The refraction layer with the high refractive index can remarkably improve the condensation degree of light on the brightness enhancement film, thereby improving the brightness gain of the brightness enhancement film. Meanwhile, the geometrical shapes of the condensation structures are maintained, thereby preventing the arrangement of the refraction layer from causing the change of the geometrical optical effect.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

High luminance gain metal curtain preparation method

InactiveCN103084322AIncrease brightnessHigh brightness gainPretreated surfacesCoatingsCooking & bakingPolyvinyl chloride

The invention discloses a high luminance gain metal curtain preparation method. The high luminance gain metal curtain preparation method comprises dosing, mixing, film manufacturing and baking processes sequentially. According to the dosing process, raw materials comprise, by weight, 100 parts of polyvinyl chloride (PVC) pastes, 3-10 parts of metal powder, 10-15 parts of anatase titanium dioxide, 70-85 parts of dioctyl phthalate or / and dioctyl adipate plasticizers, 3-8 parts of chlorination aliphatic ester surface treating agents, and 6-10 parts of epoxidized soybean oil heat stabilizers. The mixing process comprises the following steps: premixing all the raw materials in the dosing process S1, grinding sizing agents through a three-roll grinder, standing and dissolving, and dispersing through a dispersion machine. According to the film manufacturing process, a scraper coating machine coats the sizing agents obtained through the mixing process on a curtain blank in a scraping mode. According to the baking process, a subsection baking process with temperature increased successively is adopted for baking the curtain blank coated with the sizing agents in the scraping mode. Compared with the prior art, luminance gain of a metal curtain obtained through the method is high and can reach 3.0-3.5.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

High brightness gain metal screen coating

InactiveCN105623409AInhibit sheddingLow moisture absorptionPaints with free metalsPlasticizerPolyvinyl chloride

The invention discloses a high brightness gain metal screen coating. The coating comprises, by weight, 100 parts of polyvinyl chloride paste resin, 10-20 parts of chlorinated polyethylene, 3-10 parts of metal powder, 10-15 parts of anatase titanium dioxide, 0.5-2 parts of hollow glass powder, 70-85 parts of a plasticizer and 6-10 parts of a heat stabilizer. The hollow glass powder and the metal powder are simultaneously added to reduce the moisture absorption ability of a screen and inhibit shedding of the glass powder, and shedding of the hollow glass powder having light weight is more difficult than shedding of common powder; and the hollow glass powder and the metal powder are simultaneously used, so the production cost of the screen is reduced, and the produced screen has low cost and high brightness gain.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

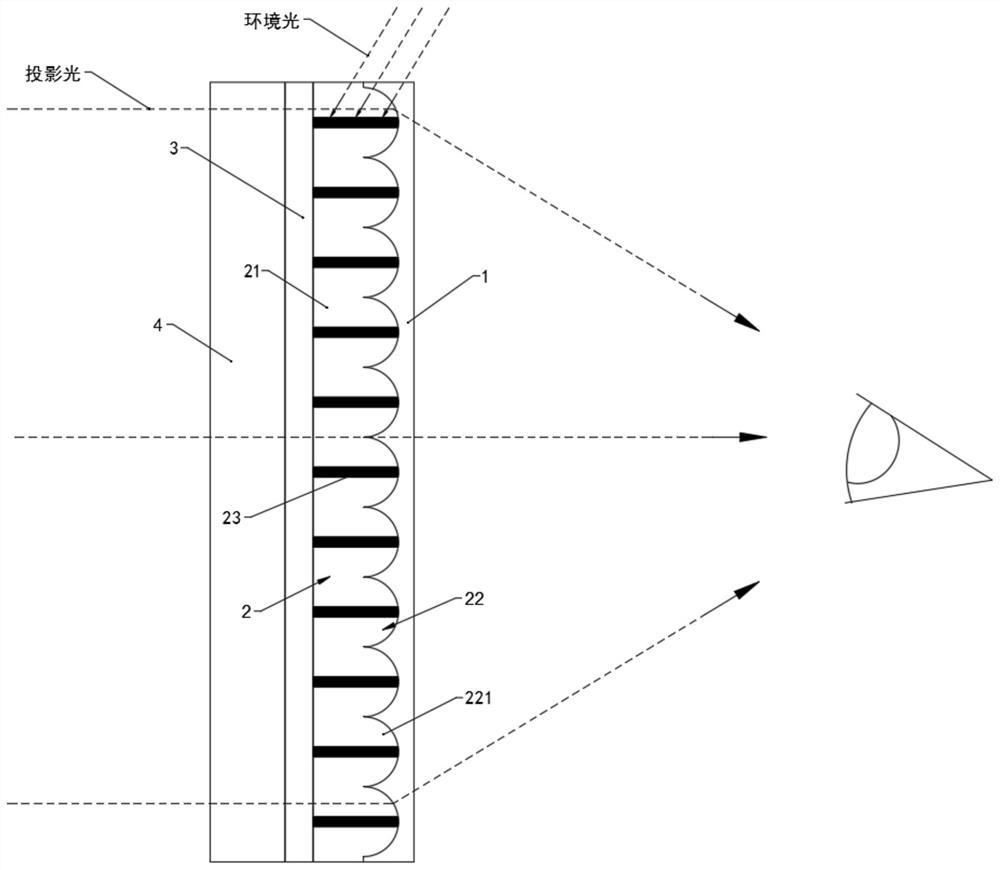

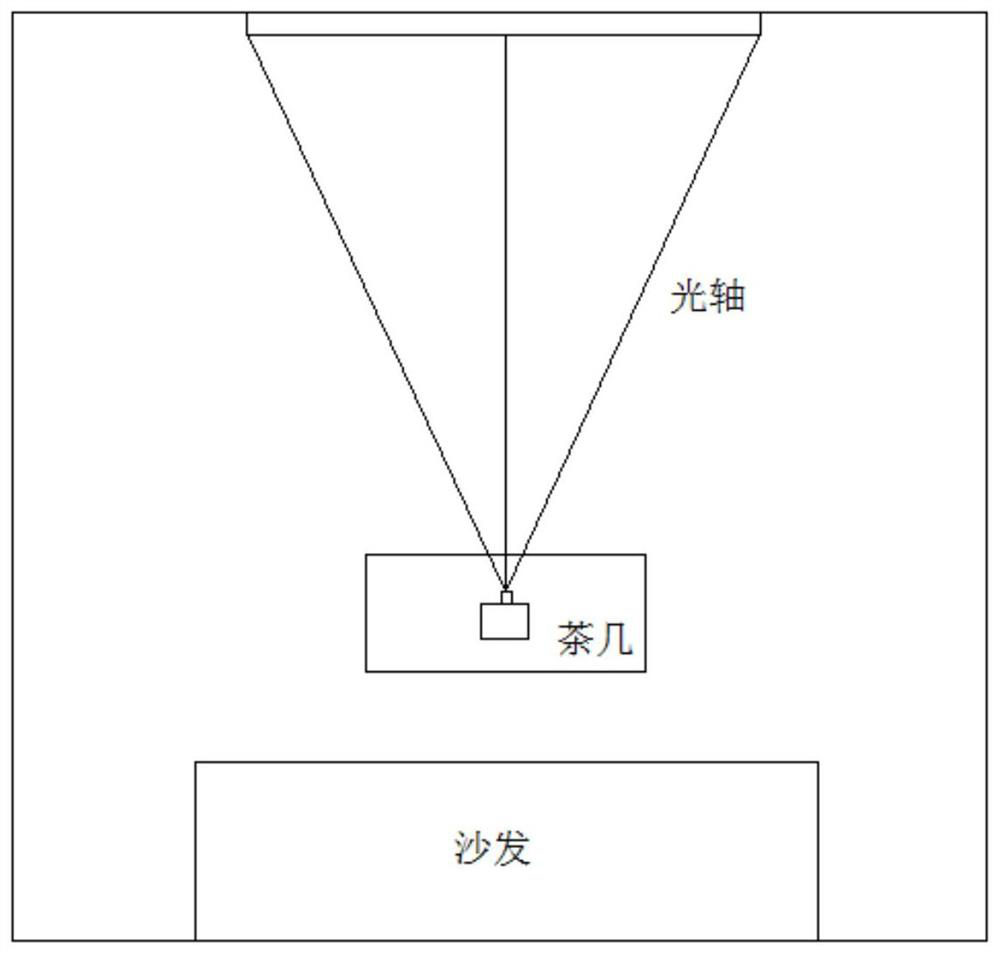

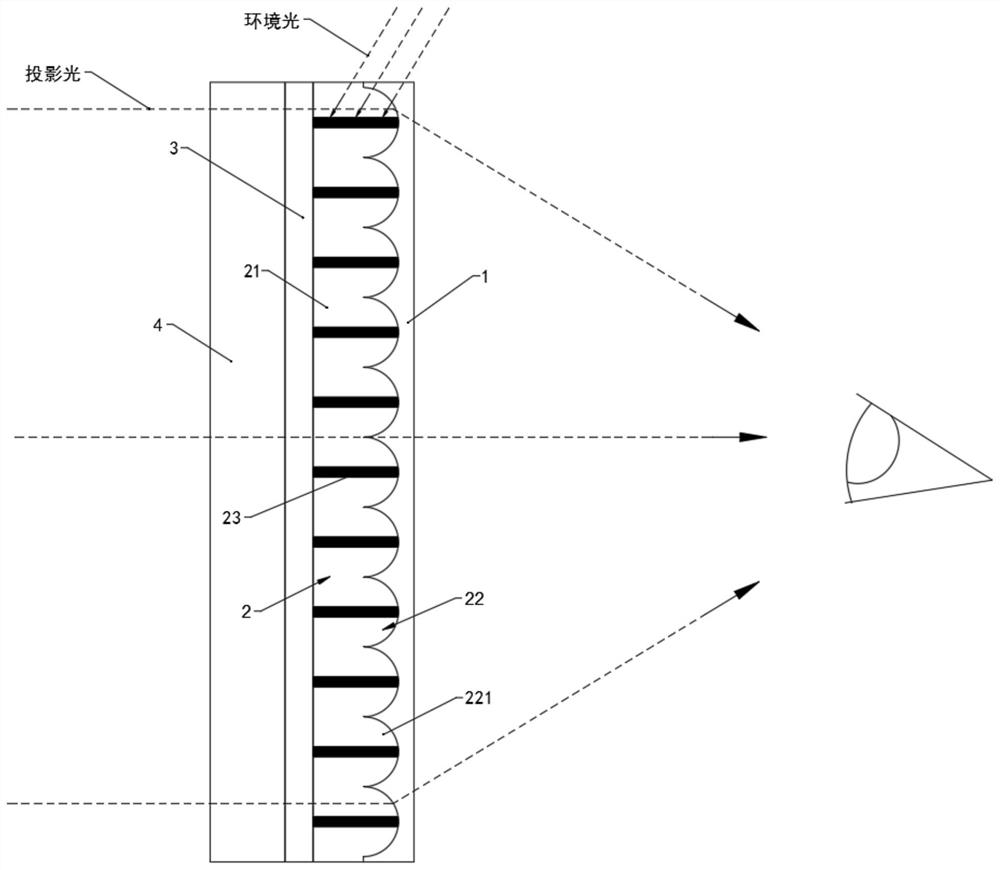

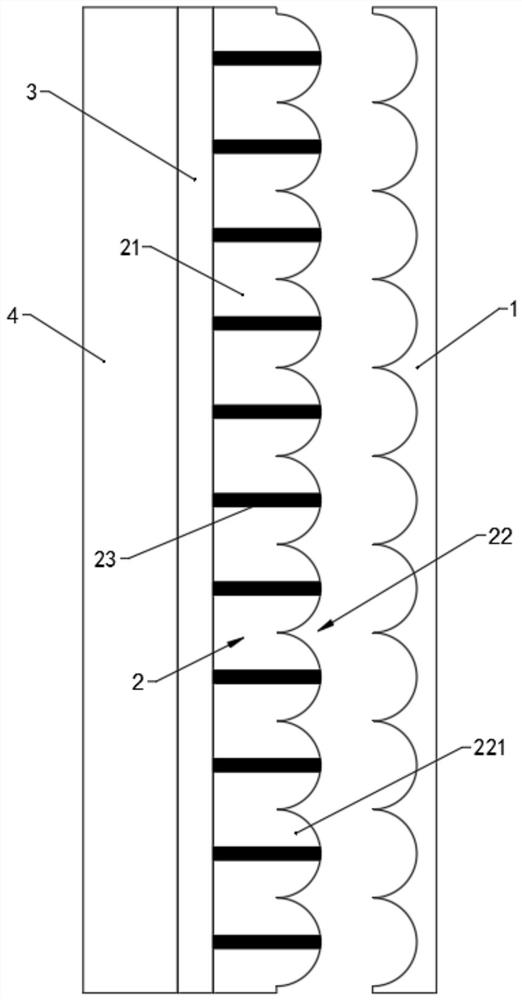

Projection screen and projection system

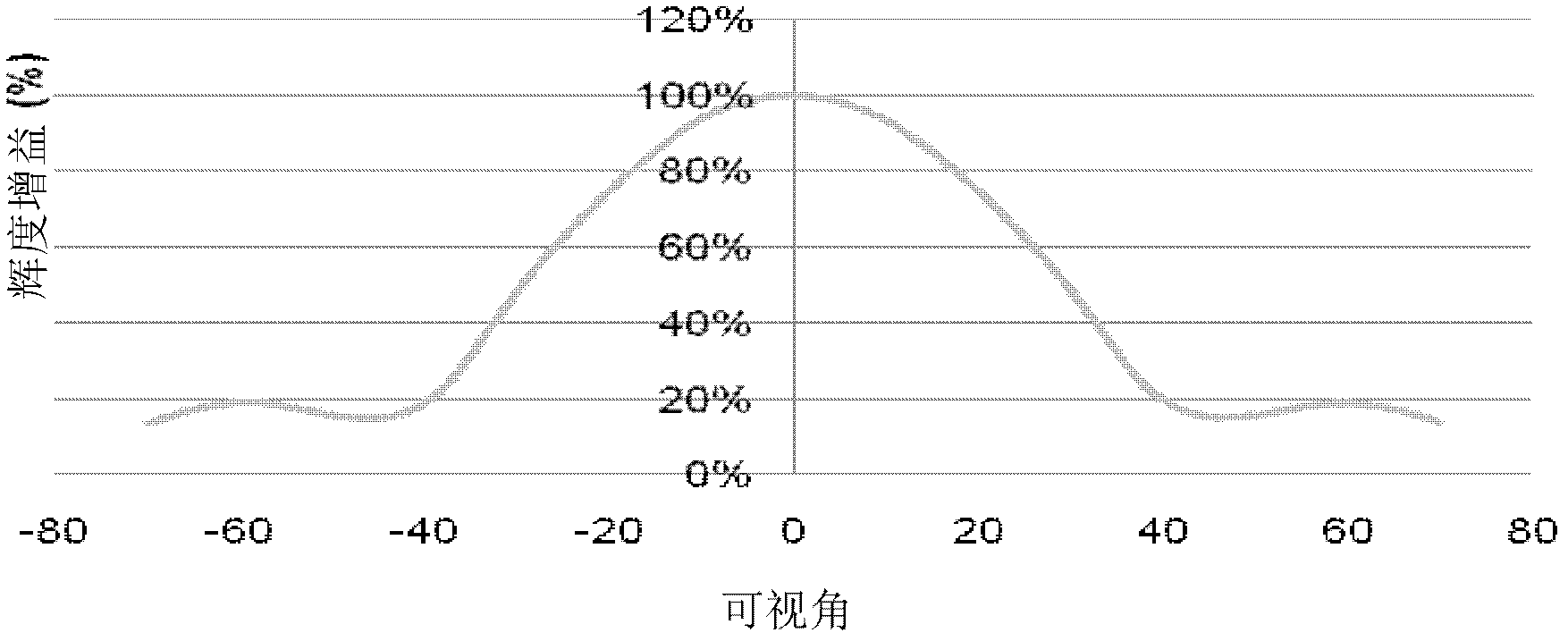

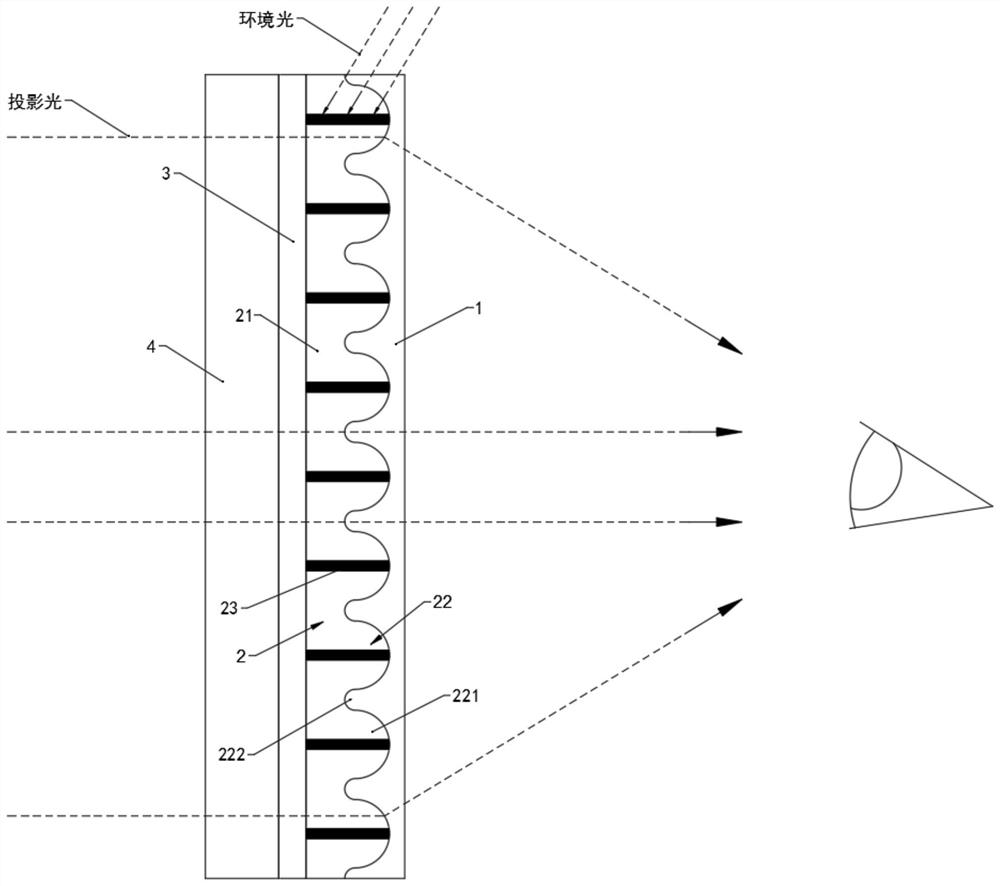

PendingCN113219776AHigh brightness gainMaintain Contrast Consistency Against Ambient LightProjectorsProjection screenLight beam

The invention discloses a projection screen, the projection screen at least comprises a diffusion layer, a reflection layer and a microstructure layer, the reflection layer is arranged between the diffusion layer and the microstructure layer, the microstructure layer comprises a plurality of Fresnel structures, each Fresnel structure comprises a first surface and a second surface, the reflection layer is partially formed on the first surfaces of the Fresnel structures, the diffusion layer is used for inputting an incident projection beam to the reflection layer, and the reflection layer reflects the projection beam to a field of view area. In this way, the brightness gain and the anti-ambient light contrast consistency of the projection screen can be improved.

Owner:APPOTRONICS CORP LTD

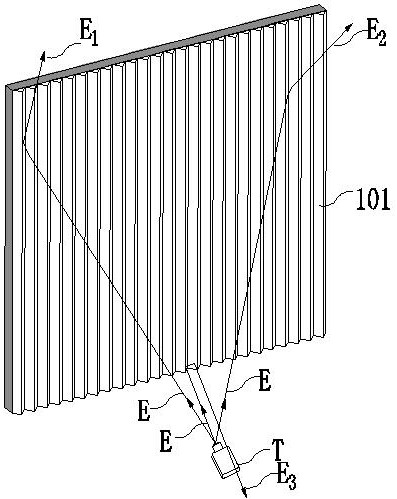

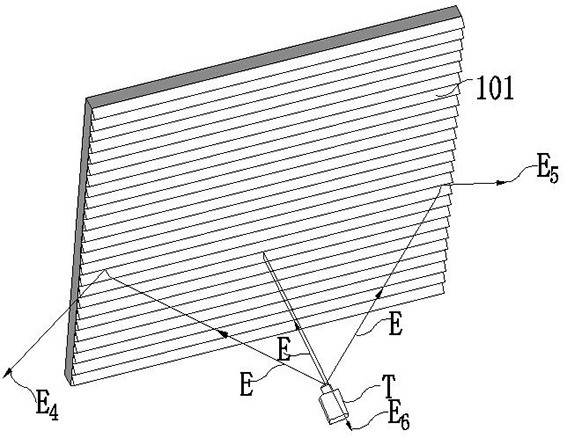

Projection curtain with optical structure

The invention discloses a projection curtain with an optical structure. The projection curtain comprises a base material layer and an optical structure layer, wherein the optical structure layer of the projection curtain with the optical structure comprises a plurality of long-strip-shaped concave mirror structures arranged on a base material layer, the optical structure layer comprises a plurality of reflection structures and a plurality of light-transmitting structures, the reflection structures and the light-transmitting structures are arranged alternately and are all arranged on the base material layer, when light emitted by the projection equipment irradiates the projection curtain with the optical structure, the reflection structure reflects the light to converge the light, and the refraction structure can transmit ambient light, so that the ambient light is absorbed by the base material layer. The projection curtain with the optical structure is low in cost, can absorb ambient light, improves the brightness gain of the screen, maintains the original visual angle, and improves the image brightness of the curtain.

Owner:SHENZHEN HOLOKOOK TECH CO LTD

Slurry for making high-brightness metal screen

InactiveCN105694605APrevent oxidationHigh brightness gainInorganic pigment treatmentPaints with free metalsPolyvinyl chlorideSlurry

The invention discloses slurry for making a high-brightness metal screen. The invention is characterized in that the slurry is composed of, by weight, 100 parts of PVC paste resin, 3-10 parts of metal powder with a glassy thin layer on the surface, 10-15 parts of anatase titanium dioxide, 70-85 parts of dicapryl phthalate or / and dioctyl adipate plasticizer, 3-8 parts of a chlorinated fatty acid ester surface conditioning agent and 6-10 parts of an epoxidized soybean oil heat stabilizer, wherein the weight ratio of the glassy material to the metal powder without the glassy thin layer is 0.1-10%. From the perspective of formula, high-brightness gain of the metal screen is realized. As the glassy thin layer is arranged on the surface of the metal powder, the metal powder can be prevented from being oxidized during the roasting process, and the glassy thin layer on the surface can increase brightness gain of the screen. The metal screen with high-brightness gain which is obtained by the above method can be used as a 3D projection screen.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

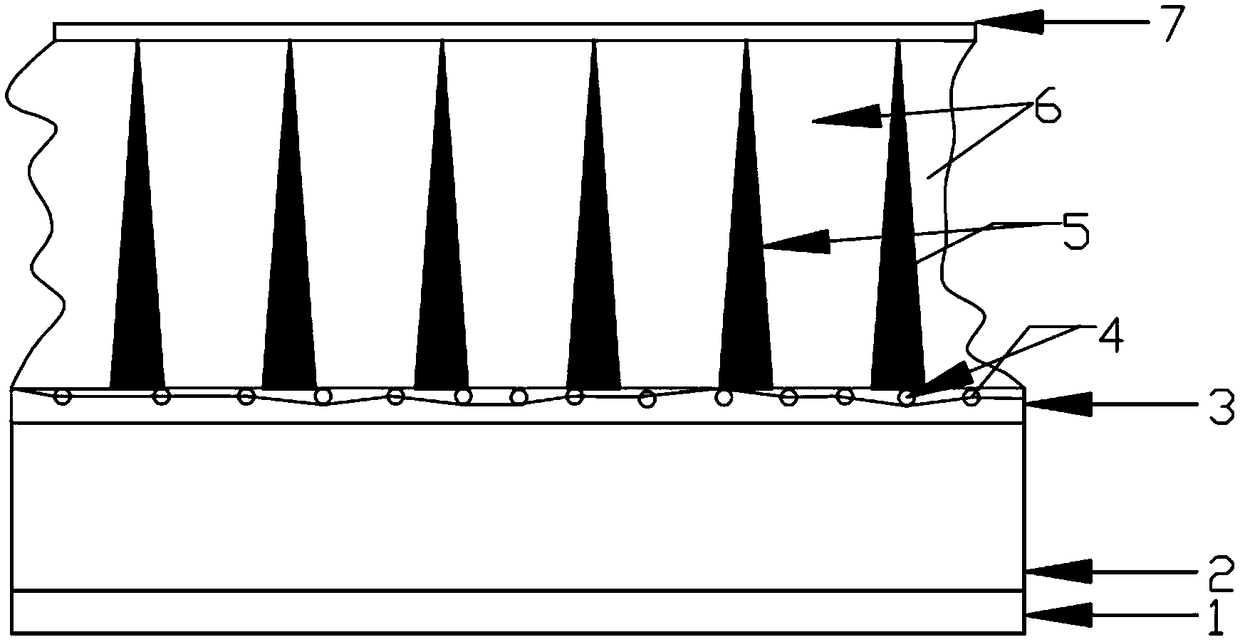

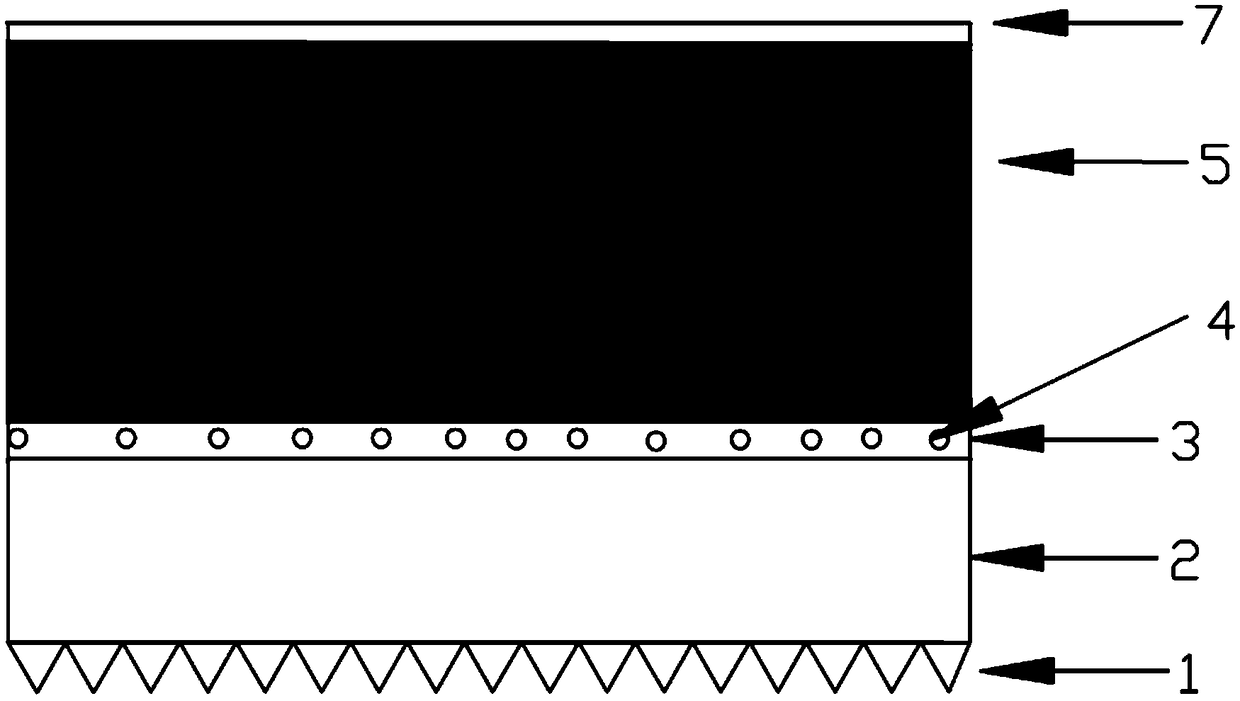

Projection screen and manufacturing method of projection screen

ActiveUS9395616B2Improve image contrastHigh brightness gainMirrorsDiffusing elementsFresnel lensProjection screen

A projection screen that includes a transparent substrate, a plurality of micro-lens structures, a Fresnel lens structure, a light absorption layer, and a diffusive reflection layer is provided. The transparent substrate has a first surface and a second surface opposite to the first surface. The micro-lens structures are located at the first surface of the transparent substrate. The Fresnel lens structure is located at the second surface of the transparent substrate. The light absorption layer includes a light absorption portion. The diffusive reflection layer includes a plurality of dispersive diffusive reflection portions connected to the Fresnel lens structure. The deviation degrees of the diffusive reflection portions with respect to a plurality of optical axes of the corresponding micro-lens structures increase together with an increase in slopes of inclined surfaces of the Fresnel lens structure on the corresponding optical axes. A manufacturing method of the projection screen is also provided.

Owner:NANO PRECISION TAIWAN LTD

Projection screens and projection systems

PendingCN109188849AIncrease contrastHigh color reproductionProjectorsProjection screenRefractive index

The invention provides a projection screen and a projection system, which relate to the technical field of projection, wherein the projection screen comprises a substrate layer; a light filt film layer is for on one side of that substrate layer; an imaging layer formed on a side of the substrate layer remote from the filter film layer; a light-reflecting film layer is formed on a side of that image layer remote from the substrate layer. The filter film layer includes a first film layer and a second film layer having a different refractive index from the first film layer, so that the filter film layer can transmit light of red, green and blue three colors and absorb light of other colors other than red, green and blue three colors. The reflective film layer includes a third film layer and afourth film layer having a different refractive index from the third film layer so that the reflective film layer is capable of reflecting light of red, green, and blue colors and absorbing light ofother colors than red, green, and blue colors. With the above-mentioned setting, the problem that the imaging effect of the existing projection screen is poor can be improved.

Owner:CHENGDU FSCREEN SCI TECH

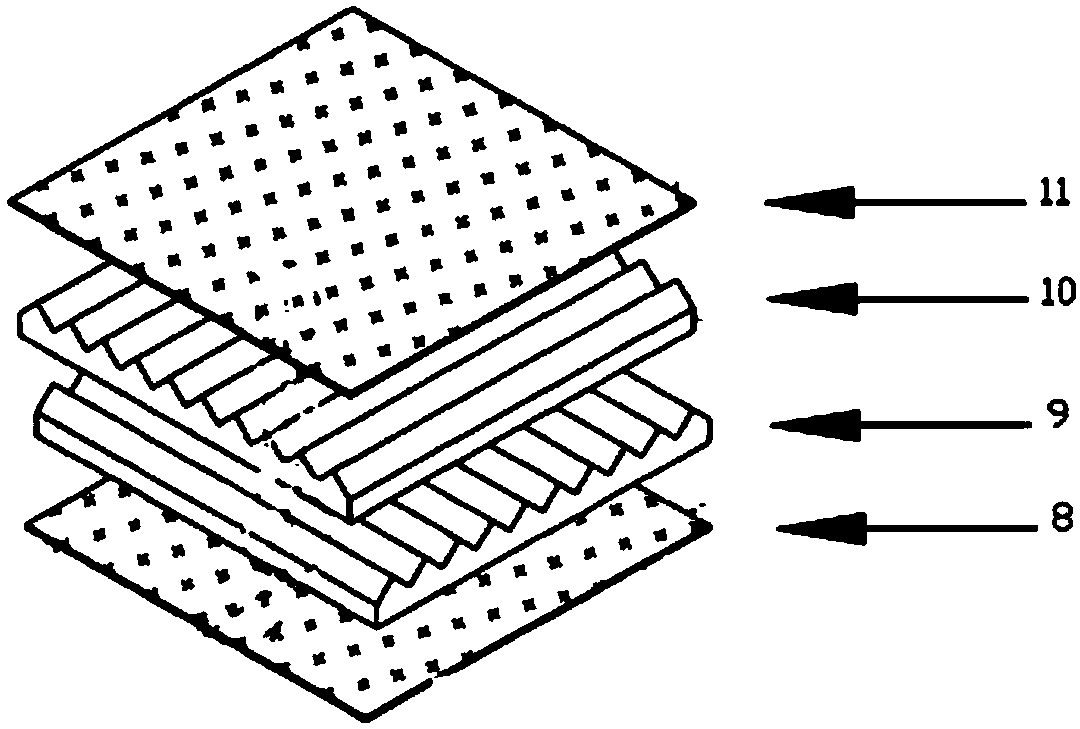

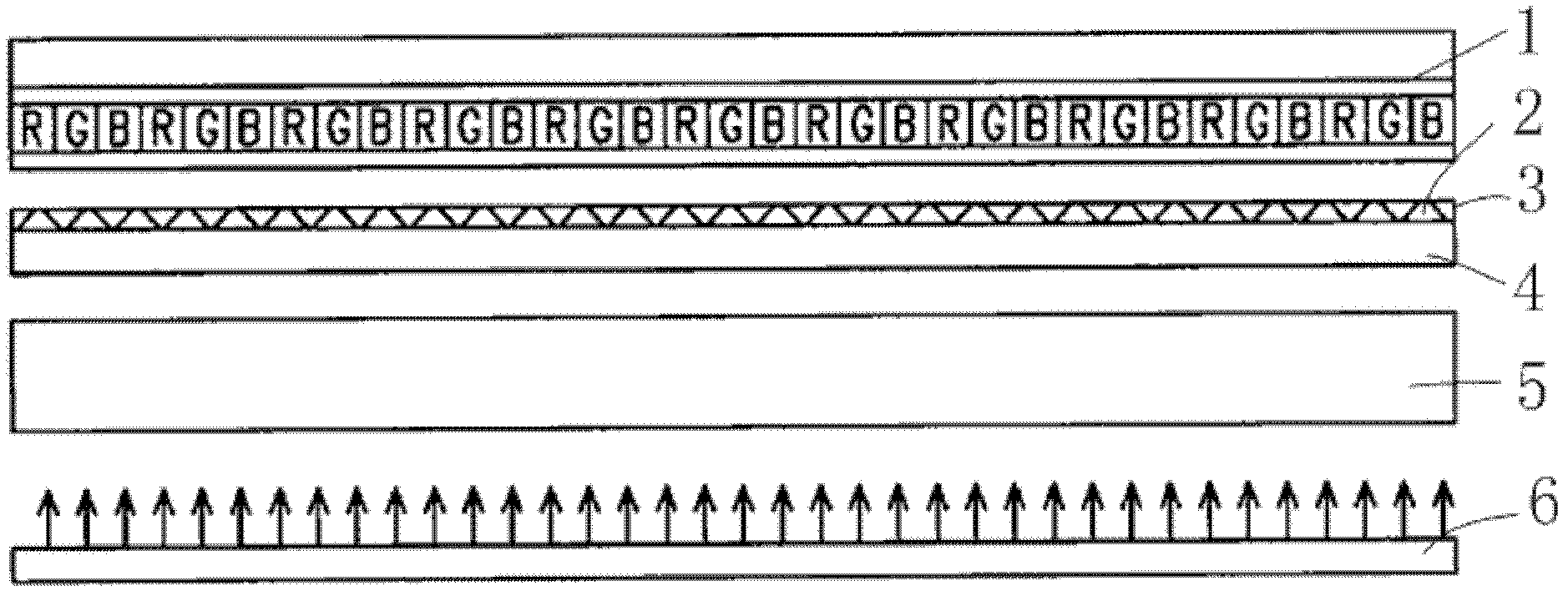

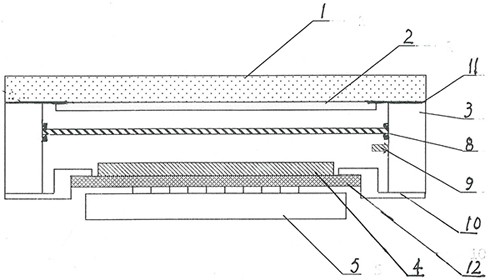

Composite optical membrane, backlight module and liquid crystal display device

InactiveCN102425760AGuaranteed Optical PerformanceSolve phenomena such as muraPrismsDiffusing elementsDiffusionLiquid-crystal display

The invention discloses a composite optical membrane, a backlight module and a liquid crystal display device. The composite optical membrane comprises at least two prism type membranes which are arranged in an intersecting way; diffusion sheets with high positive penetration rates are attached to the prism type membranes; and the positive penetration rates of the lower diffusion sheets with high positive penetration rates are higher than 85 percent and lower than 95 percent. In a framework formed by the lower diffusion sheets and the intersecting prism type membranes in the invention, the relation between the positive penetration rates of the lower diffusion sheets and the luminance gain of the entire optical membrane is integrally reached, and an appropriate range of the positive penetration rates of the lower diffusion sheets with high positive penetration rates is determined, so that the optical functions of the lower diffusion sheets can be ensured, the luminance gain of the composite optical membrane is increased remarkably, and appropriate luminance is achieved for the backlight module.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

A multi-touch anti-light hard glass rear projection smoky crystal screen

The invention discloses a multi-touch anti-light hard glass rear-projection ink crystal screen, which relates to the technical field of screen equipment, and comprises a ink crystal layer, an optical structure base layer, an imaging layer and a hard base layer which are arranged sequentially from front to back ; Wherein, the hard base layer is transparent and has a light-transmitting circuit board inside, and the light-transmitting circuit board is used to detect the user's action of pressing the smoky crystal layer; the imaging layer is used to allow the projection device to project light onto it for imaging; the optical structure The base layer includes a line grating base layer and a structure layer. The rear side of the line grating base layer is bonded to the imaging layer. The structure layer includes a plurality of convex structures that are horizontally protruded on the front side of the line grating base layer; A plurality of horizontal light-absorbing layers. The invention has the advantages of maximizing the light absorption area, good user experience and good imaging effect.

Owner:SUZHOU HAISHENG XIANGHE LIGHT SCI & TECH

Optical projection screen and projection system

ActiveCN111624843BImprove light energy utilizationUniform light energy utilizationProjectorsLight energyProjection screen

An optical projection screen, comprising a surface layer, an imaging layer, and a reflective layer sequentially arranged along the viewer's direction, the reflective layer including an optical microstructure layer, and the optical microstructure layer consists of several optical microstructure blocks along the optical projection The screen is formed in a vertical or horizontal array, and each of the optical microstructure blocks includes two main reflective surfaces, and the intersecting line of the main reflective surfaces in space has an included angle with the screen plane of the optical projection screen; by the above The optical projection screen and the projector form a projection system. The present invention adjusts the reflection of projection light toward the viewer by controlling the angle between the optical microstructure block and the screen plane, which can significantly reduce the loss of projection light emitted by the projector from the optical projection screen, improve the utilization rate of light energy, and make the optical projection screen And the projection system has extremely high brightness gain and brightness uniformity, which solves the problem of poor brightness gain and uniformity of the existing projection system.

Owner:CHENGDU FSCREEN SCI TECH

A miniaturized high-gain low-light night vision imaging device

ActiveCN109547718BMiniaturizationHigh brightness gainTelevision system detailsColor television detailsCMOSIlluminance

The invention discloses a miniaturized high-gain low-illuminance night vision imaging device, which is mainly used for military helmet night vision devices and similar night vision products used in related industries. Its main technical scheme: the input end of the tube shell is sealed and welded with the input window, and the end of the tube shell is sealed and welded with the output end of the CMOS image sensor; the photocathode is plated in the effective area of the inner surface of the input window; the microchannel plate is installed on the second side of the tube shell. Between the metal ring and the third metal ring; the CMOS image sensor is welded to the ceramic substrate, and the output end of the CMOS image sensor is connected to the readout circuit board. The invention proves through the trial that the phenomenon of low gain of the original device is fundamentally overcome, the gain of the device can be effectively improved, the miniaturization is realized, and the requirement of single-person night vision products such as military helmet night vision devices is met.

Owner:NORTH NIGHT VISION TECH

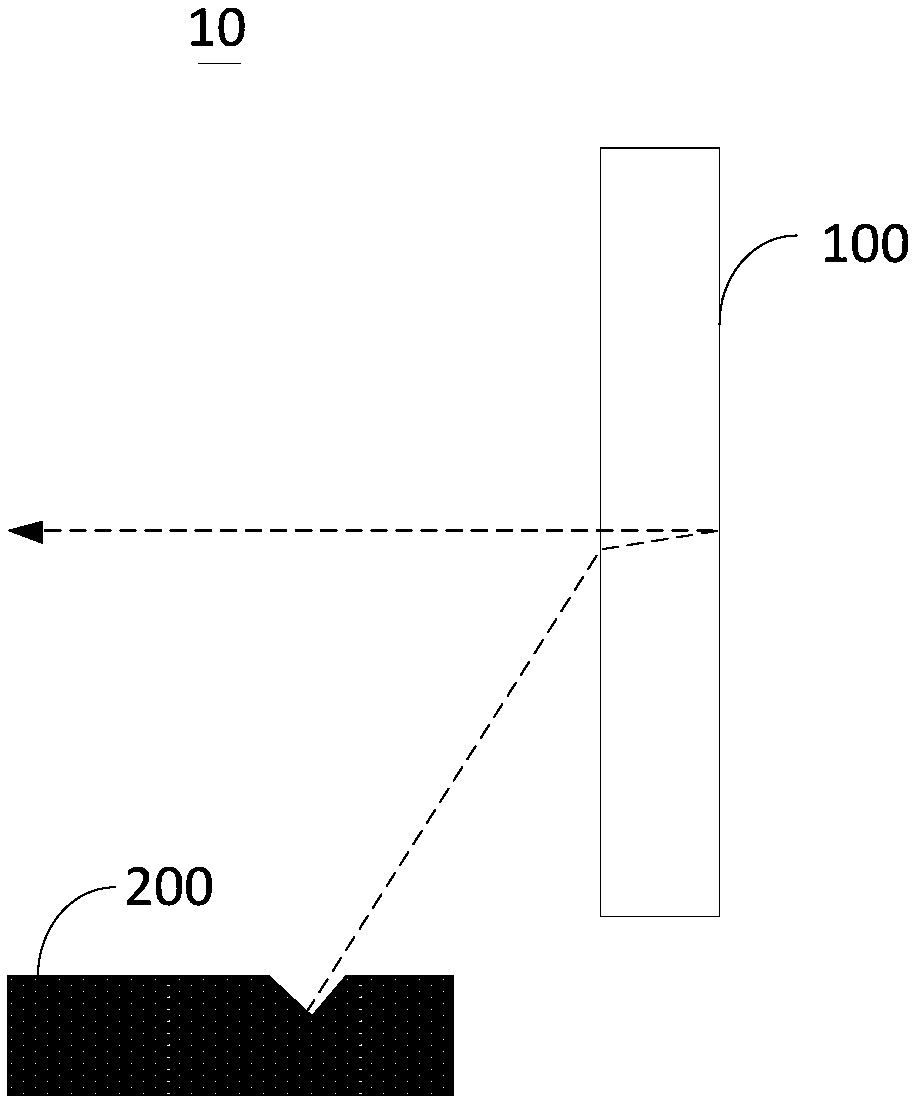

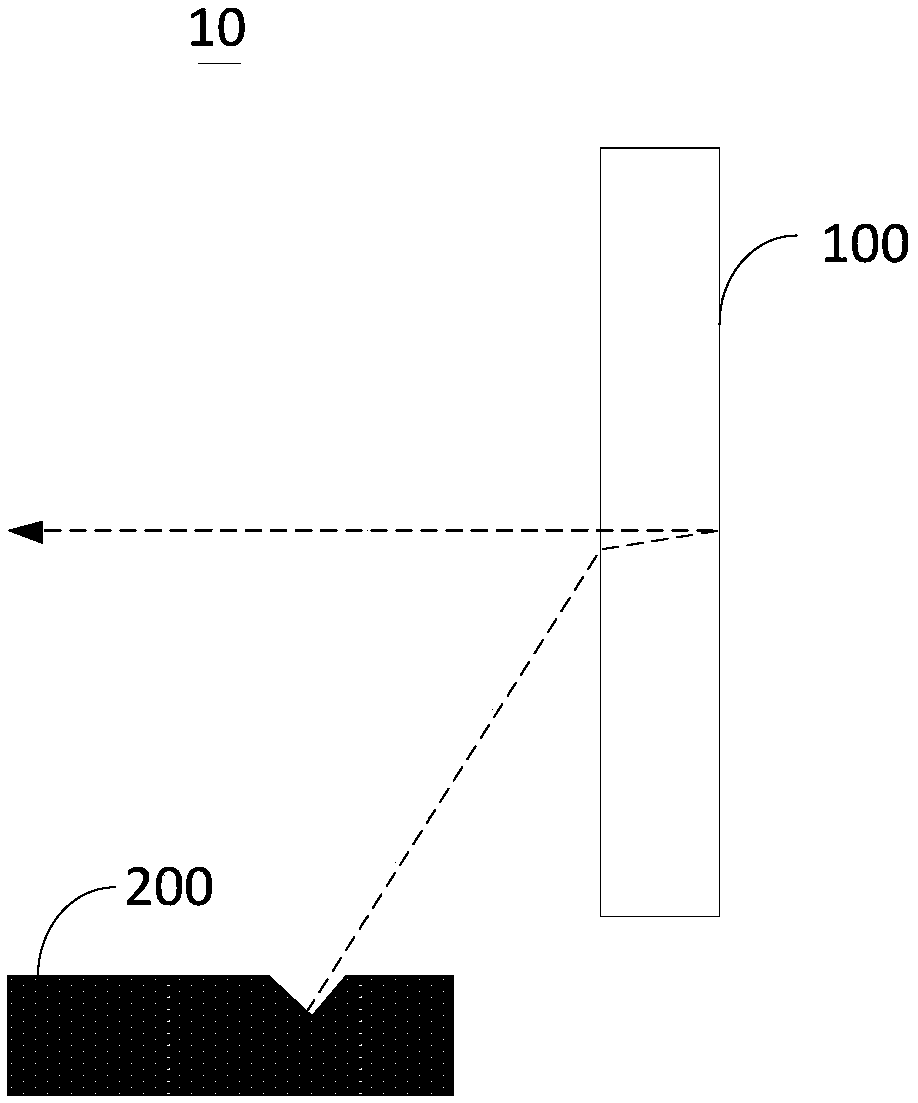

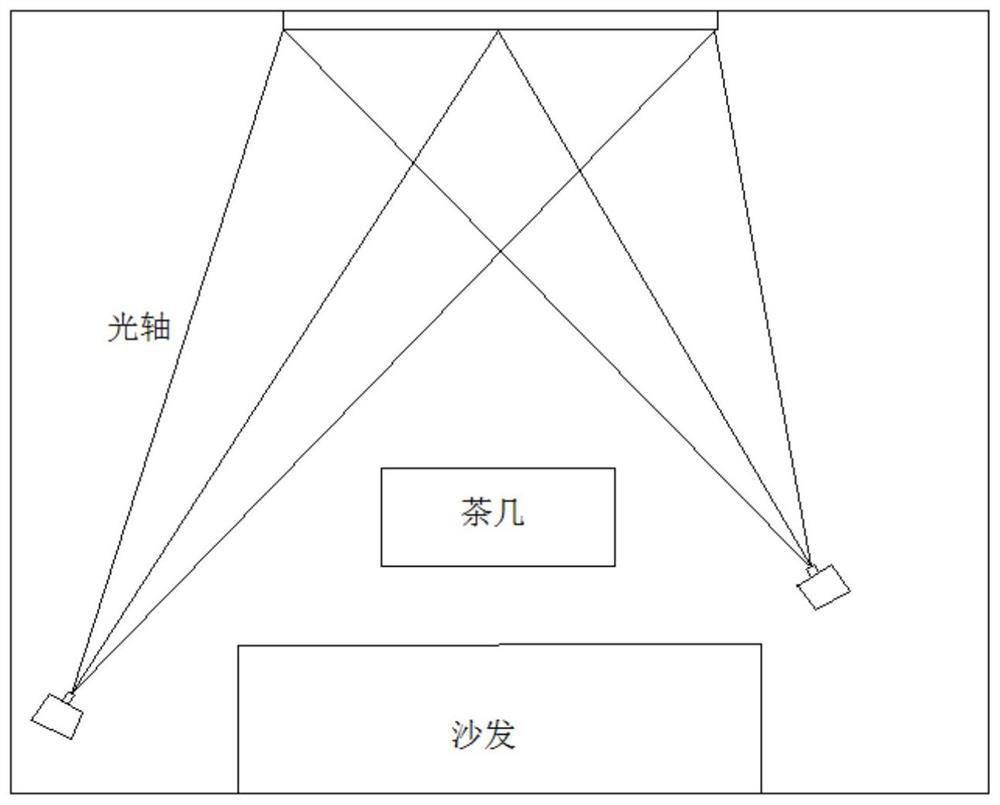

Reflective lateral projection screen and projection system

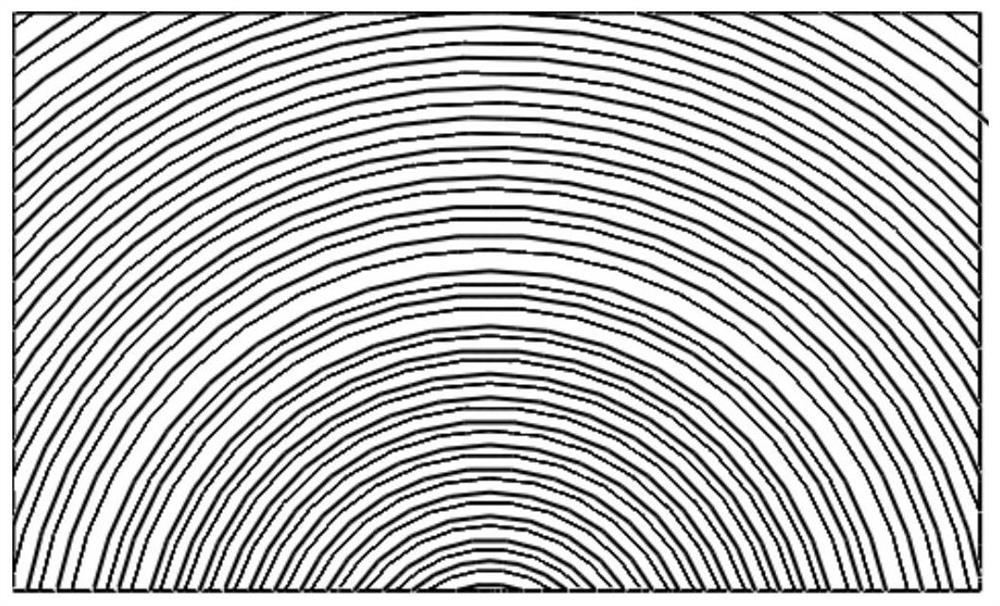

InactiveCN112255875AImprove light energy utilizationHigh brightness gainProjectorsProjection screenImage contrast

The invention discloses a reflection type lateral projection screen and a projection system, the projection screen comprises a reflection function layer with the same size as the projection surface ofthe projection screen, and the reflection function layer comprises a concentric circle microstructure layer and a reflection material layer which are sequentially arranged from outside to inside along the thickness direction of the projection screen; wherein the concentric circle microstructure layer is obtained by intercepting a part of rectangular area from a complete concentric circle microstructure array, and the circle center of a microstructure unit in the concentric circle microstructure layer deviates from the perpendicular bisector of the projection screen. The invention aims to provide a reflective lateral projection screen and a projection system, and solves the problems of low brightness gain, brightness uniformity offset, horizontal view angle bilateral asymmetry and low image contrast of the existing projection screen and projection system.

Owner:CHENGDU FSCREEN SCI TECH

Optical film

PendingCN110133762AReduce absorptionHigh brightness gainPrismsNon-linear opticsTransmitted lightOptical film

The invention discloses an optical film. The optical film comprises a first optical film structure layer with a support layer and at least one second optical film structure layer without a support layer, wherein the first optical film structure layer and the second optical film structure layer are mutually fixed; and an air structure is left between the first optical film structure layer and the second optical film structural layer. Through setting the air structure, the existence of the air structure enables the light collecting effect to be effectively enhanced and enables the brightness tobe effectively improved; and compared with the optical films with two support layers on the market, the base materials of the optical film are decreased, so that the absorption and reflection, for thelight, of the base materials are decreased, the transmitted light is increased, and the optical gain is further improved.

Owner:ZHEJIANG JINHUI OPTOELECTRONIC MATERIAL CO LTD

Metal texture curtain used for auxiliary equipment for final assembly of three-dimensional (3D) image projection and playing system

The invention relates to a metal texture curtain used for auxiliary equipment for the final assembly of a three-dimensional (3D) image projection and playing system. The metal texture curtain is provided with a hard base plate or a tough soft base cloth, and a metal reflective coating made of silver ink, silver powder, reflective powder, a light stabilizer, curing agent and the like is coated on the surface of the base plate or the base cloth. The product has the advantages of simple structure, splicing and installation convenience, good polarizer focusing effect, texture display performance and the like. The metal texture curtain provided by the invention has the advantages of high luminance gain, large visual angle, good color reproduction, resistance to ambient light interference, easiness of cleaning, elegant appearance, no color cast and the like. The coating surface of the curtain does not damage polarized light, vivid 3D images can be seen, and the image viewing effect is good.The product can be configured and used in the occasions of 3D family cinemas built by common families, company 3D conference studios, small 3D cinemas and the like.

Owner:XIAN SHENGSHI NETWORK INFORMATION

High luminance gain metal curtain preparation method

InactiveCN103084322BIncrease brightnessHigh brightness gainPretreated surfacesSpecial surfacesCooking & bakingPolyvinyl chloride

The invention discloses a high luminance gain metal curtain preparation method. The high luminance gain metal curtain preparation method comprises dosing, mixing, film manufacturing and baking processes sequentially. According to the dosing process, raw materials comprise, by weight, 100 parts of polyvinyl chloride (PVC) pastes, 3-10 parts of metal powder, 10-15 parts of anatase titanium dioxide, 70-85 parts of dioctyl phthalate or / and dioctyl adipate plasticizers, 3-8 parts of chlorination aliphatic ester surface treating agents, and 6-10 parts of epoxidized soybean oil heat stabilizers. The mixing process comprises the following steps: premixing all the raw materials in the dosing process S1, grinding sizing agents through a three-roll grinder, standing and dissolving, and dispersing through a dispersion machine. According to the film manufacturing process, a scraper coating machine coats the sizing agents obtained through the mixing process on a curtain blank in a scraping mode. According to the baking process, a subsection baking process with temperature increased successively is adopted for baking the curtain blank coated with the sizing agents in the scraping mode. Compared with the prior art, luminance gain of a metal curtain obtained through the method is high and can reach 3.0-3.5.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

An optical projection screen and projection system

ActiveCN111624844BImprove light energy utilizationUniform light energy utilizationProjectorsLight energyProjection screen

An optical projection screen and a projection system belong to the field of optical projection technology. The optical projection screen includes a surface layer, an imaging layer, and a reflection layer arranged in sequence along the direction of the viewer. The reflection layer includes an optical microstructure layer. A number of optical microstructure blocks arranged in sequence in the vertical direction of the projection screen are formed along a concentric arc array or a number of optical microstructure blocks arranged in sequence in the horizontal direction of the optical projection screen are formed along an elliptical arc array with the center at the same point; the optical microstructure block It includes two main reflective surfaces, and the intersecting line of the main reflective surfaces in space has an included angle with the curtain plane of the optical projection screen. The present invention adjusts the reflection of the projected light toward the viewer by controlling the angle between the optical microstructure block and the screen plane, significantly reduces the loss of the projected light emitted by the optical projection screen to the projector, improves the utilization rate of light energy, and makes the optical projection screen and projection The system has extremely high brightness gain and brightness uniformity.

Owner:CHENGDU FSCREEN SCI TECH

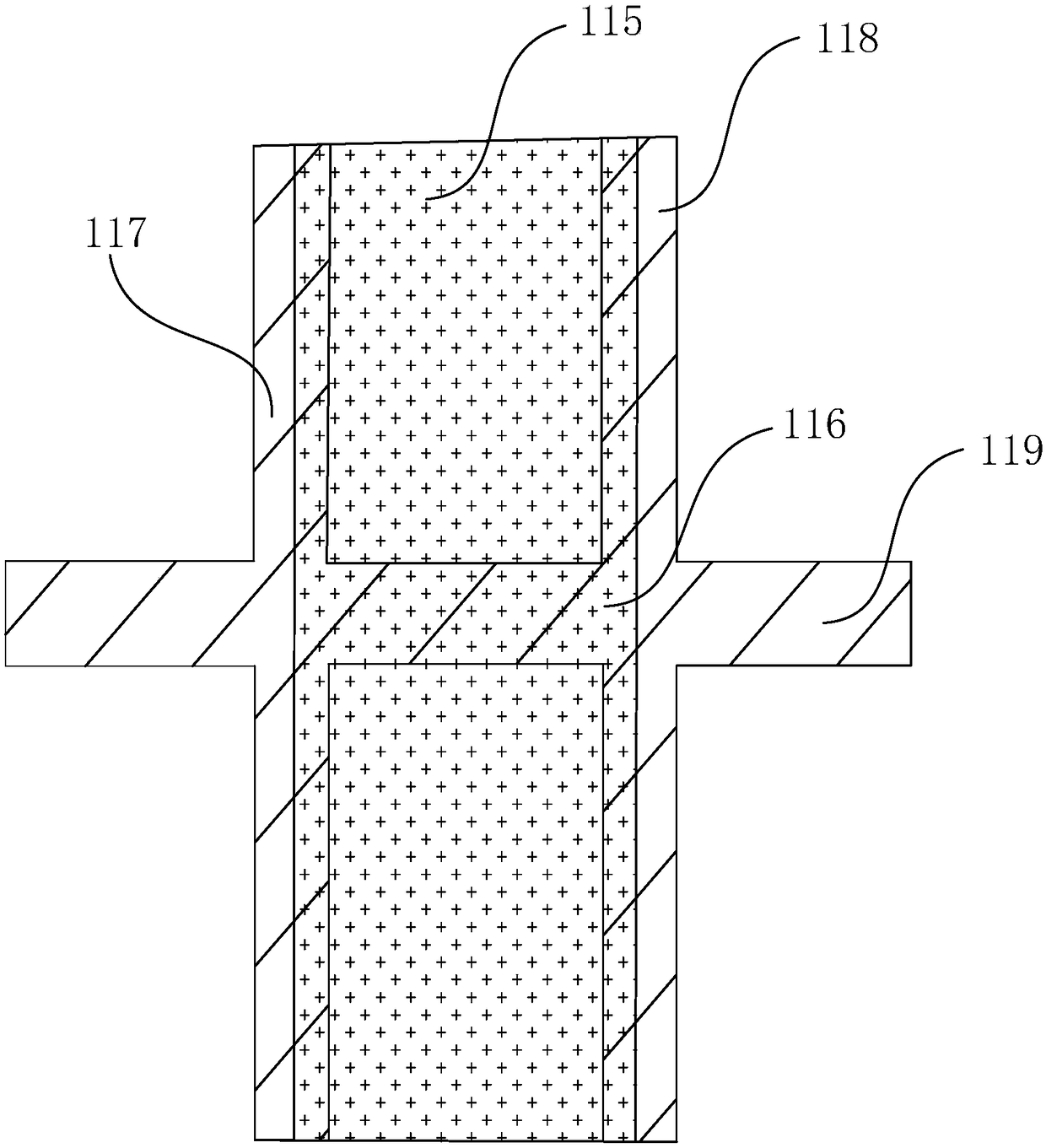

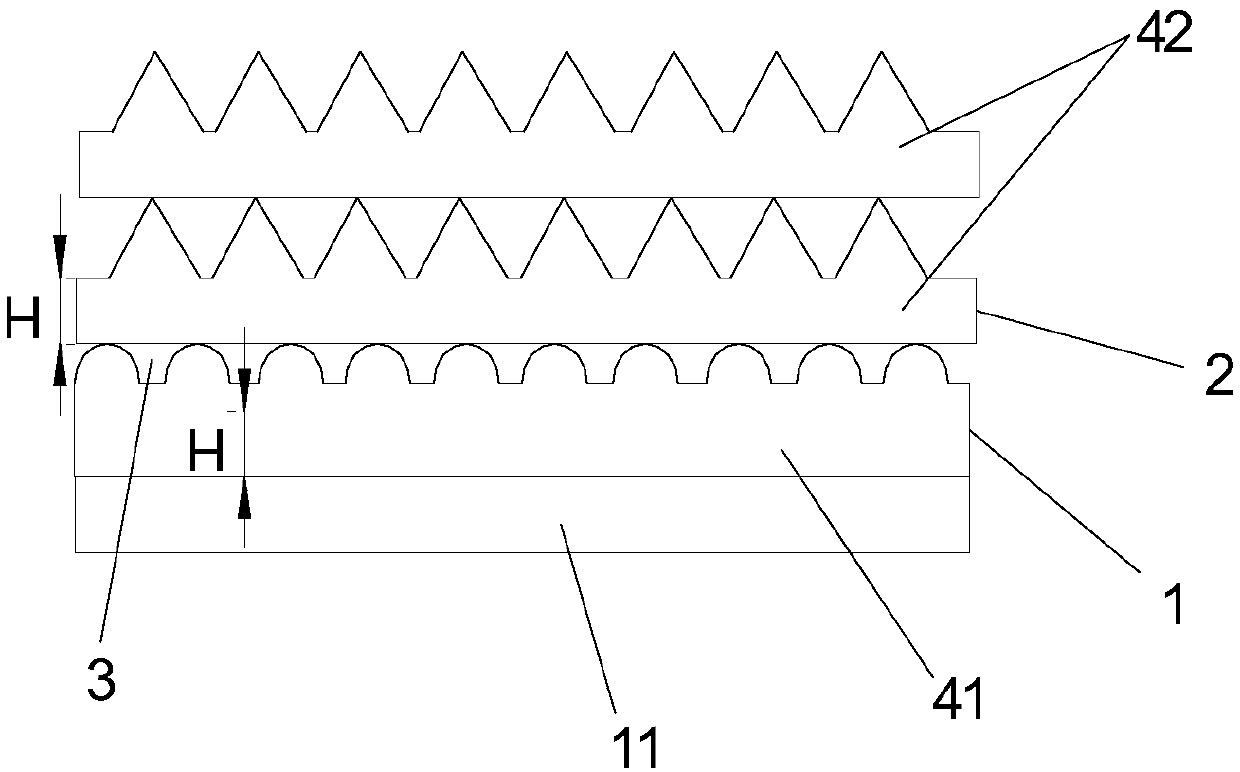

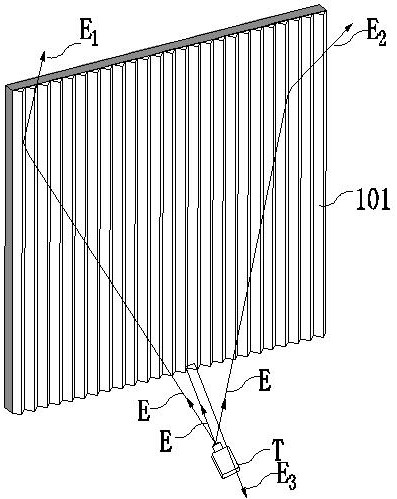

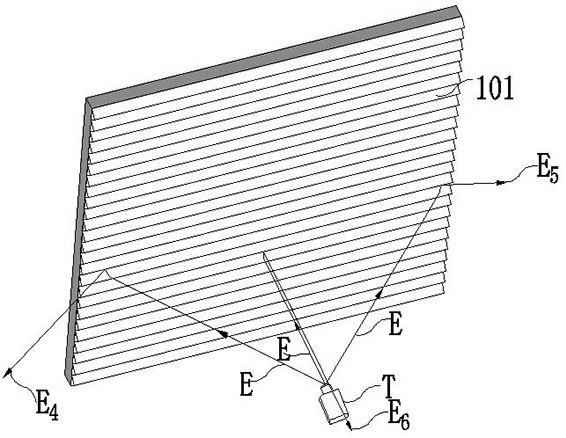

a brightening film

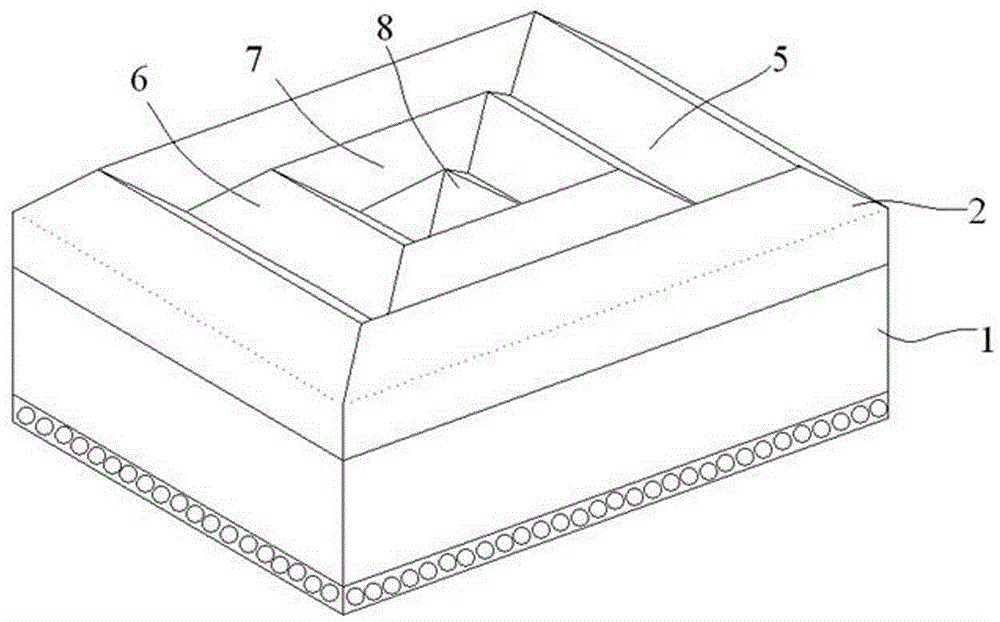

ActiveCN103823261BAdjust convergence angleReduce the number of sheets usedDiffusing elementsConvex structureOptoelectronics

The invention discloses a bright enhancement film which comprises a base material layer and a condensation layer, wherein concave-convex structures are formed in the surface of the condensation layer in the length direction and the width direction of the bright enhancement film. According to the refraction and reflection effects of concave-convex structures in the surface of the condensation layer in the length direction and the width direction on light rays, the convergence angle of the emergent light rays can be adjusted, so that the light rays are converged towards the direction of a user. The bright enhancement film has the light ray converging function in the horizontal and vertical direction, the functions of the conventional two bright enhancement films which are vertically arranged can be realized due to one bright enhancement film in the invention, the number of the used bright enhancement films is reduced, and the cost of a backlight module is further reduced. In addition, according to the backlight module with special requirements on the positive brightness, two bright enhancement films in the invention can be overlapped, and the bright enhancement film in the invention has higher brightness gain compared with the conventional two bright enhancement films which are vertically arranged.

Owner:NINGBO DXC NEW MATERIAL TECH

Projection screen coating

InactiveCN105689246AInhibit sheddingNot easy to fall offLiquid surface applicatorsCoatingsProjection screenPlasticizer

The invention discloses a projection screen coating. The coating comprises components in parts by weight as follows: 100 parts of polyvinyl chloride paste resin, 1-8 parts of metal powder, 10-15 parts of anatase titanium dioxide, 0.5-2 parts of hollow glass powder,1-3 parts of common glass powder,70-85 parts of a plasticizer and 6-10 parts of a heat stabilizer. According to the coating, two types of glass powder and the metal powder are used together, so that the hygroscopicity of the screen is reduced; the glass powder is prevented from falling off; the hollow glass powder has the characteristic of light weight and is not liableto fall off; the two types of glass powder and the metal powder are used together, so that the production cost of the screen is reduced; and the obtained screen has high luminance gain.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

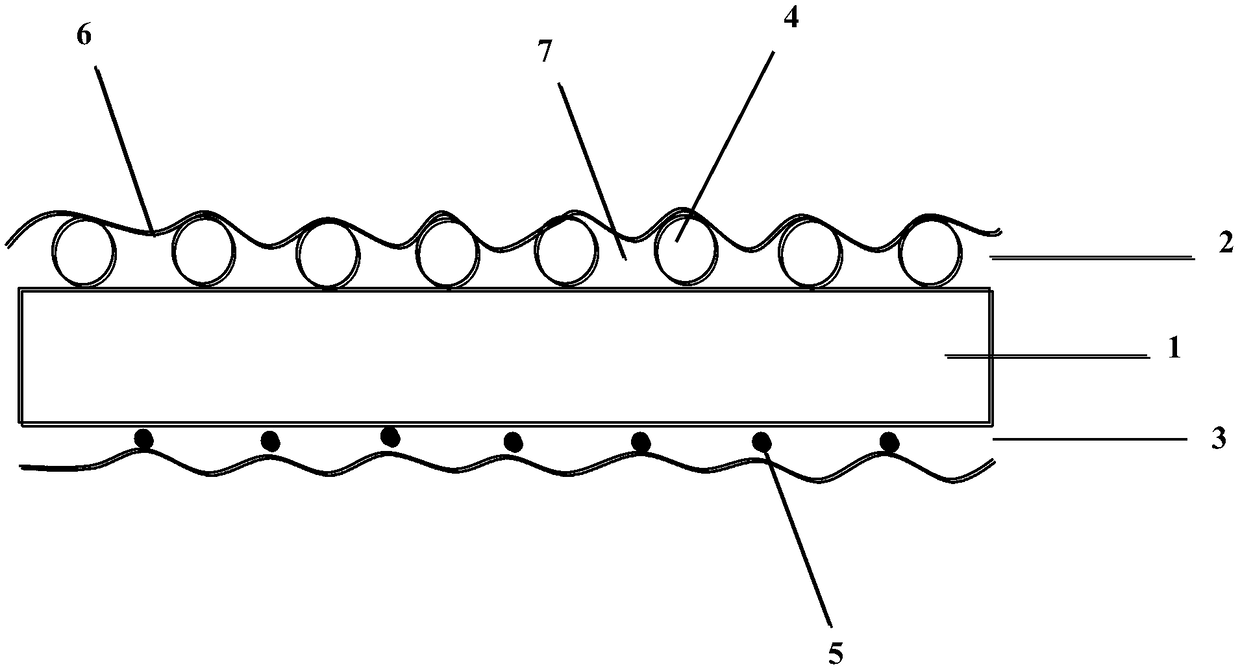

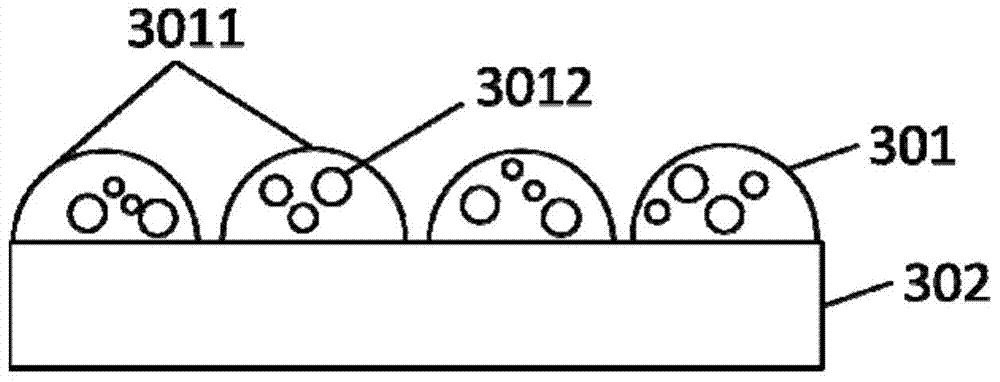

A kind of optical projection screen for display and its preparation method

ActiveCN106226988BHigh brightness gainSimple processPrismsDiffusing elementsAdhesiveProjection screen

The invention relates to optical thin film technology, and more particularly, to an optical projection screen for display and a manufacturing method thereof. In order to solve the problem that high brightness gains and wide viewing angles can not be achieved in existing projection screens, the invention provides the optical projection screen for display and the manufacturing method thereof. The screen comprises a prism layer and a base layer; the prism layer is adhered to the surface of the base layer; and the prism layer is composed of a plurality of condensing microstructures formed by an adhesive and reflective particles. The reflective particles are dispersed in the adhesive. The content of the adhesive is 100 parts, and the content of the reflective particles is 1-200 parts. The parts are parts by weight. The projection screen is with a high brightness gain, a wide viewing angle, and is widely used in laser TV and projector technology.

Owner:NINGBO EXCITON TECH

Multi-point touch light-resistant hard glass rear projection ink crystal screen

The invention discloses a multi-point touch light-resistant hard glass rear-projection ink crystal screen, which relates to the technical field of screen equipment. The screen comprises an ink crystallayer, an optical structure base layer, an imaging layer and a hard base layer which are sequentially attached from front to back; the hard base layer is transparent, a light-transmitting circuit board is arranged in the hard base layer, and the light-transmitting circuit board is used for detecting the action that a user presses the ink crystal layer; the imaging layer is used for enabling projection equipment to project light to the imaging layer for imaging; the optical structure base layer comprises a linear grating base layer and a structure layer, the rear side surface of the linear grating base layer is attached to the imaging layer, and the structure layer comprises a plurality of convex structures horizontally arranged on the front side surface of the linear grating base layer; and a plurality of horizontal light absorption layers are sequentially arranged in the optical structure base layer at intervals from top to bottom. The multi-point touch light-resistant hard glass rear-projection ink crystal screen has the advantages of maximized light absorption area, good user experience and good imaging effect.

Owner:SUZHOU HAISHENG XIANGHE LIGHT SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com