Brightening film and preparation method thereof

A technology of brightness-enhancing film and light-gathering layer, which is applied in the field of optical films, can solve the problems of excessive brightness attenuation, aging resistance of brightness-enhancing film, and poor high-temperature resistance, so as to achieve increased concentration, high refractive index, and good aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

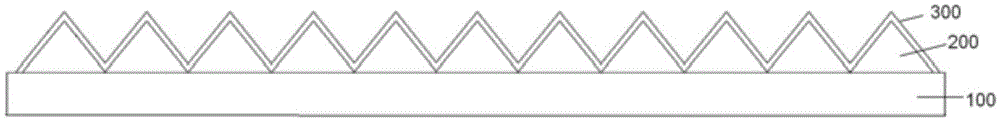

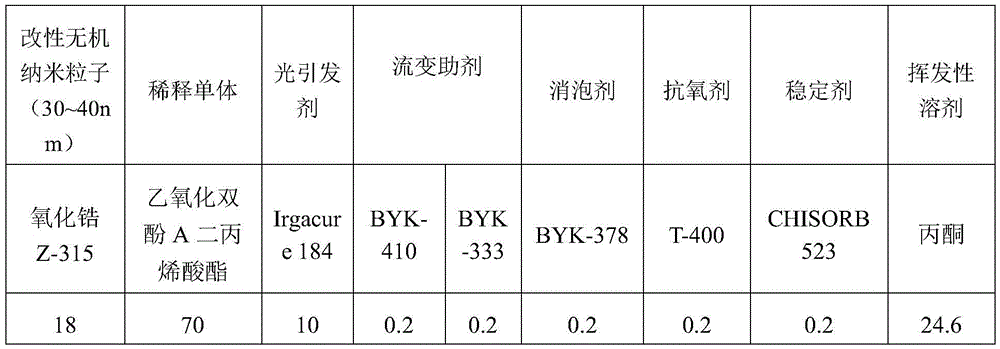

[0045] In addition, the present invention also provides a method for preparing a brightness enhancement film, which includes the following steps: forming a light-gathering layer 200 composed of a plurality of light-gathering structures on the upper surface of a substrate 100; As the raw material of the refraction layer 300, the slurry to be cured of the nanoparticles is sprayed on the upper surface of the light-gathering layer 200, and after drying, it is 2 After the photocuring treatment under the ultraviolet light, the refraction layer 300 with the concavo-convex structure matching the upper surface of the light concentrating layer 200 is formed on the upper surface; wherein, the nanoparticle slurry to be cured includes an inorganic nanoparticle composition and a volatile solvent , the inorganic nanoparticle composition includes inorganic nanoparticles, a first diluting monomer, a first photoinitiator and a first surface additive.

[0046]In the above preparation method prov...

Embodiment 1

[0050] Substrate:

[0051] Using polyethylene terephthalate (PET) film as the substrate;

[0052] Production of light-concentrating layer:

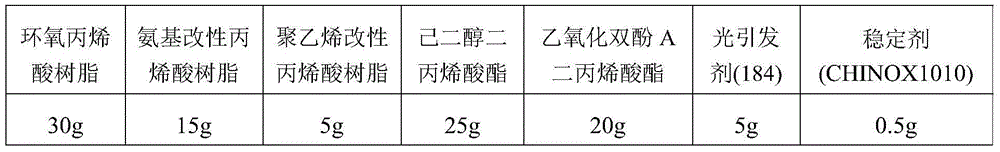

[0053] A 9-inch self-made metal mother board is placed on a hot plate and heated to 60°C. The metal mother board is composed of linear arrangements of 90-degree isosceles triangular prisms with a nominal pitch interval of 50 microns. The UV-curable resin composition (refractive index: 1.6, see the table below for the composition) was applied to the master tool using a disposable pipette. Orient the PET film so that the orientation of the linear prisms is roughly perpendicular (90 ± 20°) to the high-gain axis of the film. The master tool, photocurable resin composition and PET film were then passed through a heated nip roll at 60° C., which applied sufficient pressure to completely fill the master tool with the resin while removing entrapped air. The filled master tool was then exposed twice to UV radiation from a "D-tube" at a line spe...

Embodiment 2

[0060] Substrate:

[0061] Using polyethylene terephthalate (PET) film as the substrate;

[0062] Production of light-concentrating layer:

[0063] A 9-inch self-made metal mother board is placed on a hot plate and heated to 60°C. The metal mother board is composed of linear arrangements of 90-degree isosceles triangular prisms with a nominal pitch interval of 50 microns. The UV-curable resin composition (refractive index: 1.6, see the table below for the composition) was applied to the master tool using a disposable pipette. Orient the PET film so that the orientation of the linear prisms is roughly perpendicular (90 ± 20°) to the high-gain axis of the film. The master tool, photocurable resin composition and PET film were then passed through a heated nip roll at 60° C., which applied sufficient pressure to completely fill the master tool with the resin while removing entrapped air. The filled master tool was then exposed twice to UV radiation from a "D-tube" at a line spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com