High-luminance optical diffusion film

A technology of optical diffusion and high brightness, which is applied in the field of optical diffusion film, can solve the problem of low luminance gain of the diffusion film, and achieve the effect of excellent light concentrating effect, reduced processing cost and high luminance gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

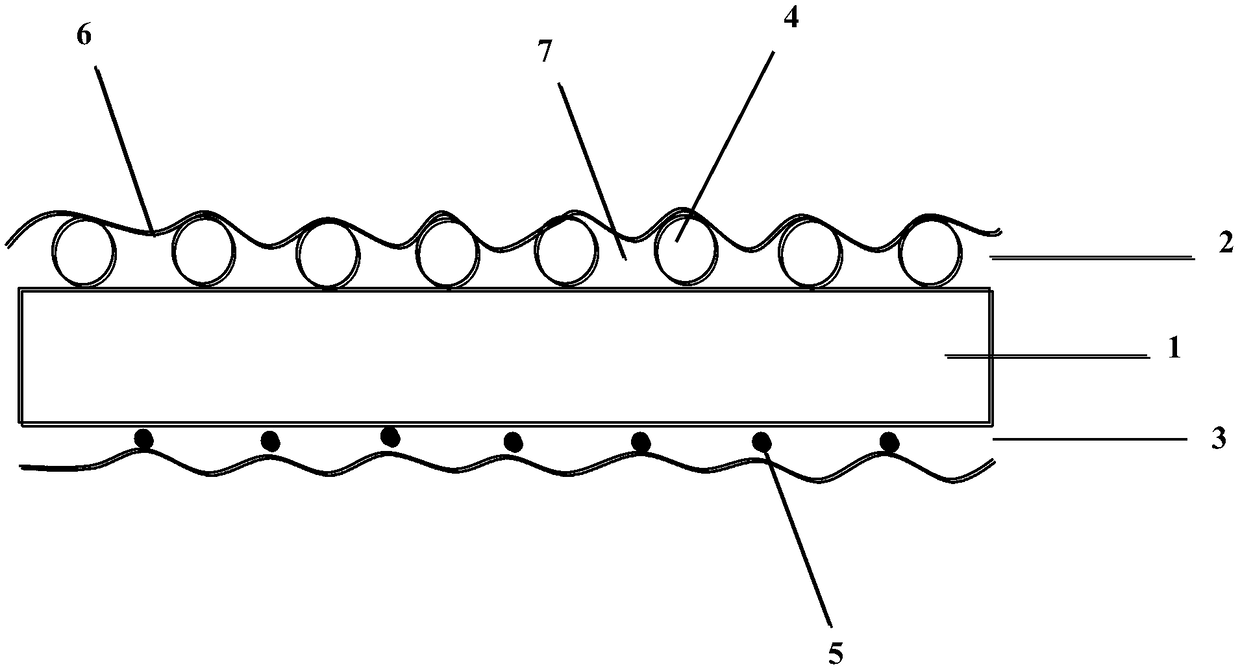

Method used

Image

Examples

Embodiment 1

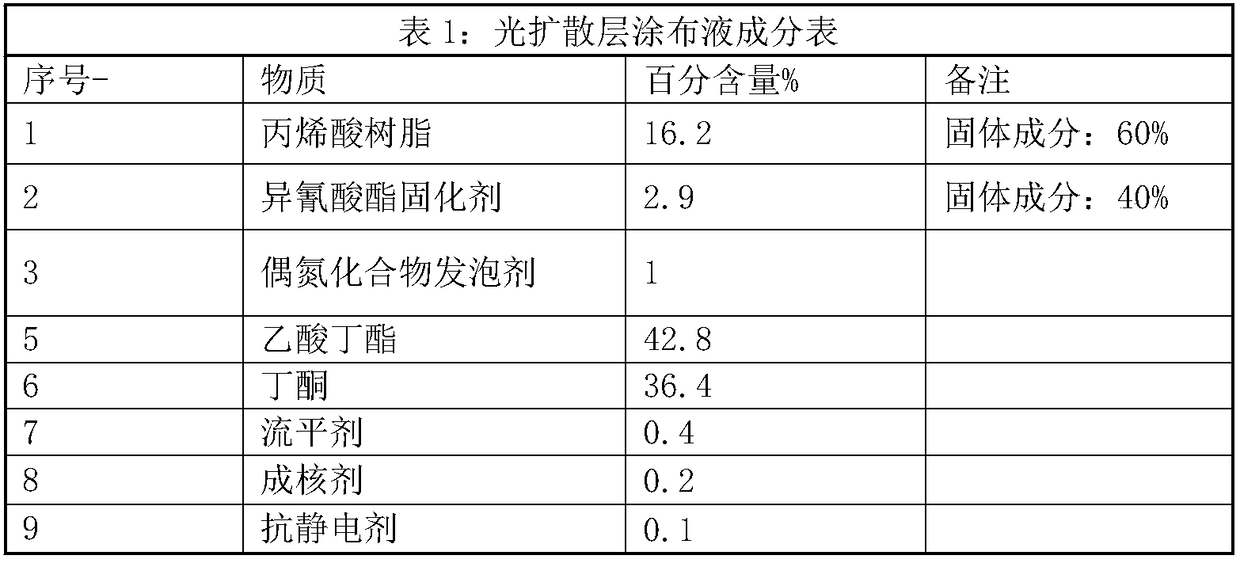

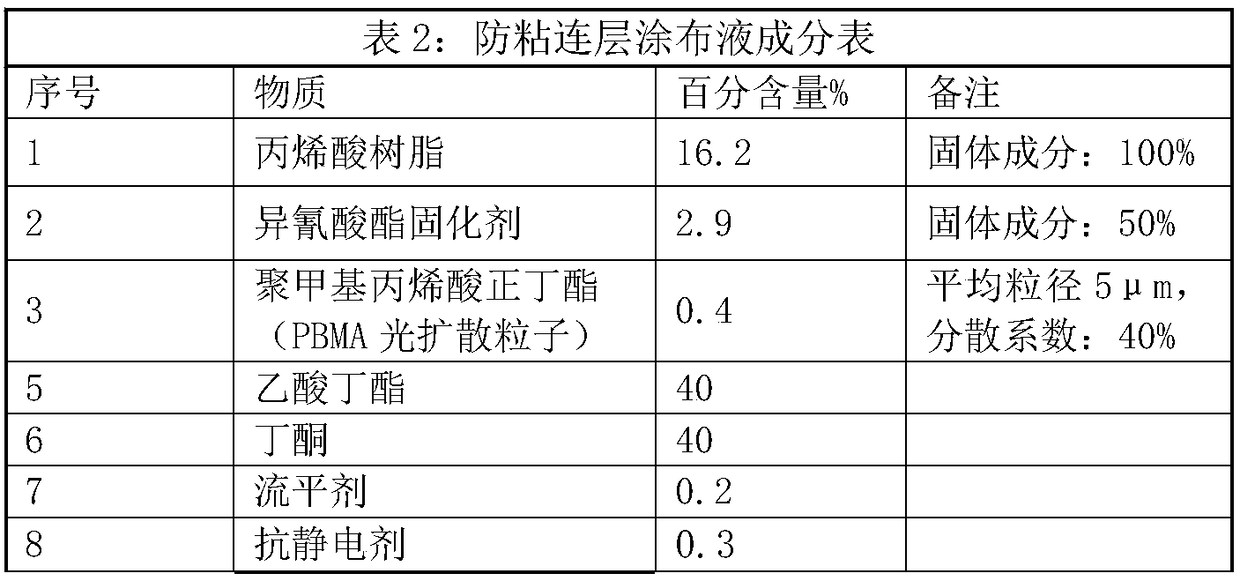

[0041] According to the material table in Table 1, add an appropriate amount of azo compound foaming agent, and stir to obtain a light diffusion layer coating solution. Coat the coating solution on the upper surface of 188 μm PET, heat and foam and simultaneously cure to obtain a thickness A light diffusion layer containing air bubbles of 5 μm; according to the material table in Table 2, the anti-adhesion layer coating solution was obtained by stirring, and the coating solution was coated on the lower surface of 188 μm PET, and heated and cured to obtain a thickness of 6 μm. Anti-blocking layer. The test results are shown in Table 21.

[0042]

[0043]

Embodiment 2

[0045] According to the material list in Table 3, add an appropriate amount of azo compound foaming agent, and stir to obtain a coating solution for the light diffusion layer. Coat the coating solution on the upper surface of 188 μm PET, heat and foam and simultaneously cure to obtain a thickness The light diffusion layer containing air bubbles is 9 μm; according to the material table in Table 4, the anti-adhesion layer coating solution is obtained by stirring, and the coating solution is coated on the lower surface of PET with a thickness of 188 μm, and heated and cured to obtain a thickness of 6 μm. Anti-blocking layer. The test results are shown in Table 21.

[0046]

[0047]

Embodiment 3

[0049] According to the material list in Table 5, add an appropriate amount of azo compound foaming agent, and stir to obtain a light diffusion layer coating solution. Coat the coating solution on the upper surface of 188 μm PET, heat and foam and simultaneously cure to obtain a thickness The light diffusion layer containing air bubbles is 13 μm; according to the material list in Table 6, the anti-adhesion layer coating solution is obtained by stirring, and the coating solution is coated on the lower surface of PET with a thickness of 188 μm, and heated and cured to obtain a thickness of 7 μm. Anti-blocking layer. The test results are shown in Table 21.

[0050]

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com