Multi-specification plate-oriented rectangular part layout method

A multi-standard, rectangular piece technology, applied in the direction of data processing application, prediction, calculation, etc., can solve the problems of poor optimization effect, no plate originals scattered and reorganized, difficult to choose and gradually relax the area, etc., to reach the scope of application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

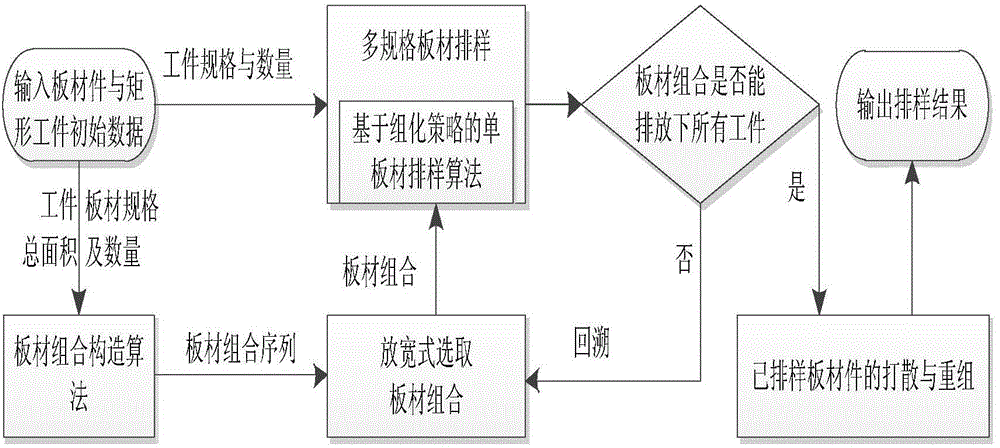

[0032] Such as figure 1 The shown rectangular layout method for multi-standard plates, the method includes the following steps:

[0033] The first step is to input the initial data of the plate and rectangular workpiece;

[0034] In the second step, according to the specifications and quantities of rectangular workpieces, the layout of multi-standard plates is carried out through the multi-standard plate layout module;

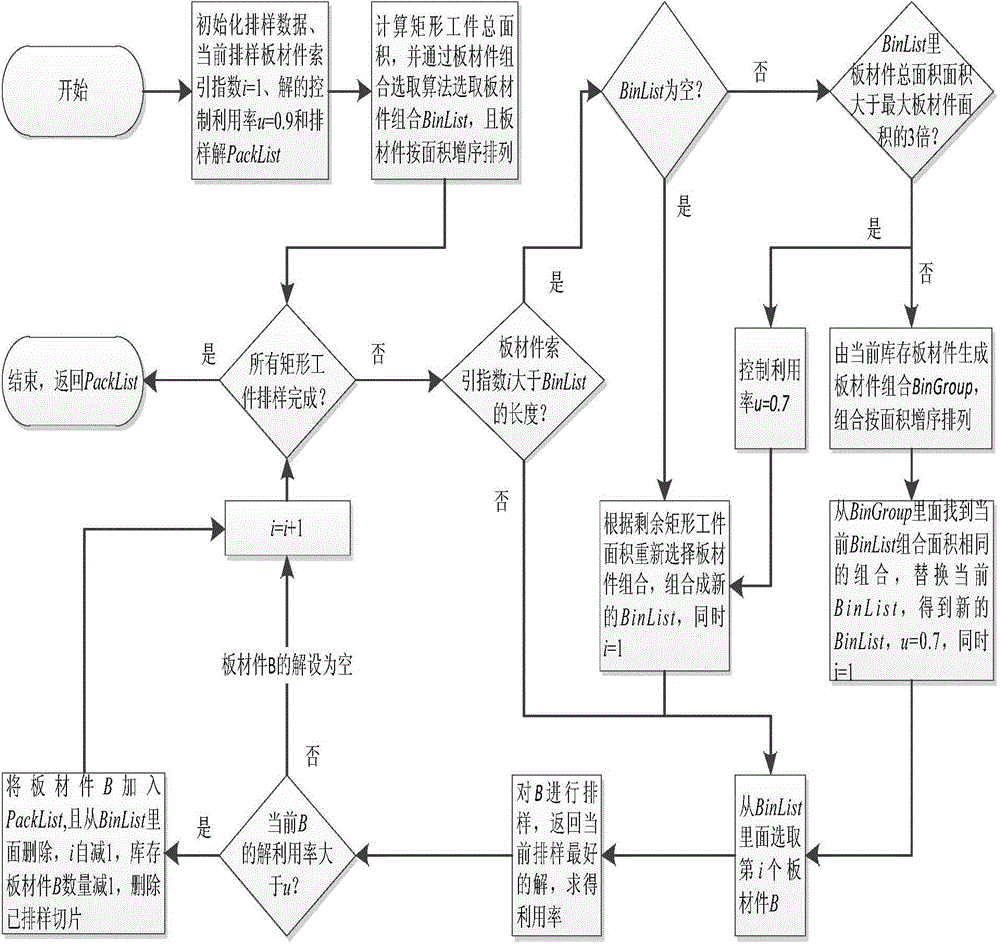

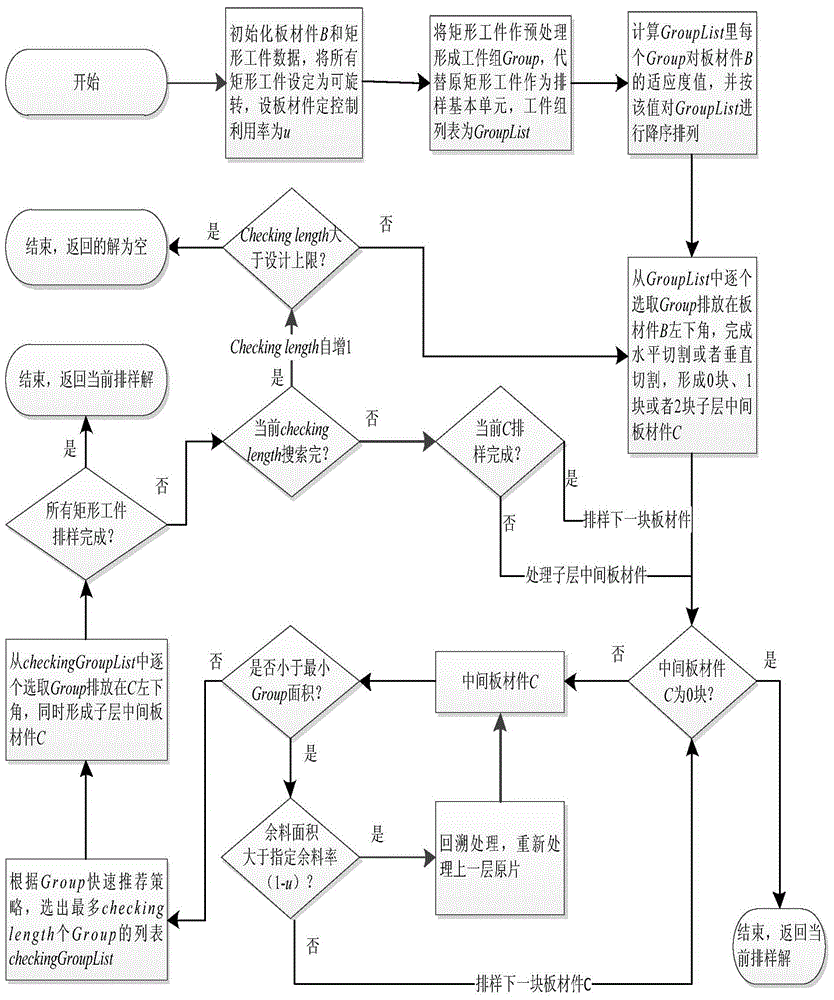

[0035] The third step is to obtain the plate combination sequence through the plate combination structure algorithm according to the total area of the workpiece, the plate specification and quantity; the plate combination sequence is relaxed to select the plate combination to obtain the plate combination; The single-plate layout algorithm of the optimization strategy calculates whether the plate combination can arrange all the workpieces, if not, it will go back to the relaxed selection of the plate combination; if it can, output the layout of the plate pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com