Flexible transverse displacement platform for rail vehicles

A technology for lateral displacement and rail vehicles, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, waste of manpower, material and financial resources, and many safety hazards, and achieve simple structure, cost saving, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

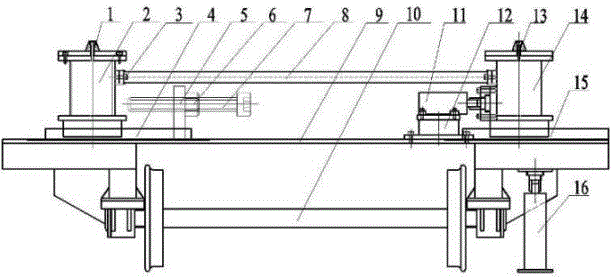

[0016] Such as figure 1 As shown, a rail vehicle flexible lateral displacement platform includes: a displacement platform 9, a running device 10, a left bearing column 2, a right bearing column 14, a left conical positioning pin 1, a right conical positioning pin 13, a left The heavy-duty linear guide rail 4, the right heavy-duty linear guide rail 15, the synchronous connection device, and the displacement hydraulic device. 1. Right heavy-duty linear guide rail 15, said left heavy-duty linear guide rail 4 is provided with a left bearing column 2, said right heavy-duty linear guide rail 15 is provided with a right bearing column 14, said left bearing column 2, right bearing column 14 Connected by a synchronous connection device, it is used to keep the distance between the left bearing column 2 and the right bearing column 14 constant; Tapered positioning pin 13; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com