Turning clamp of transmission hook blank

A hook blank and turning technology, which is applied in the directions of clamping, clamping device, manufacturing tool, etc., can solve the problems of irregular shape of transmission hook blank, turning hook handle, difficult transmission hook blank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, a turning jig of a transmission hook blank as an example of the present invention will be described based on the drawings.

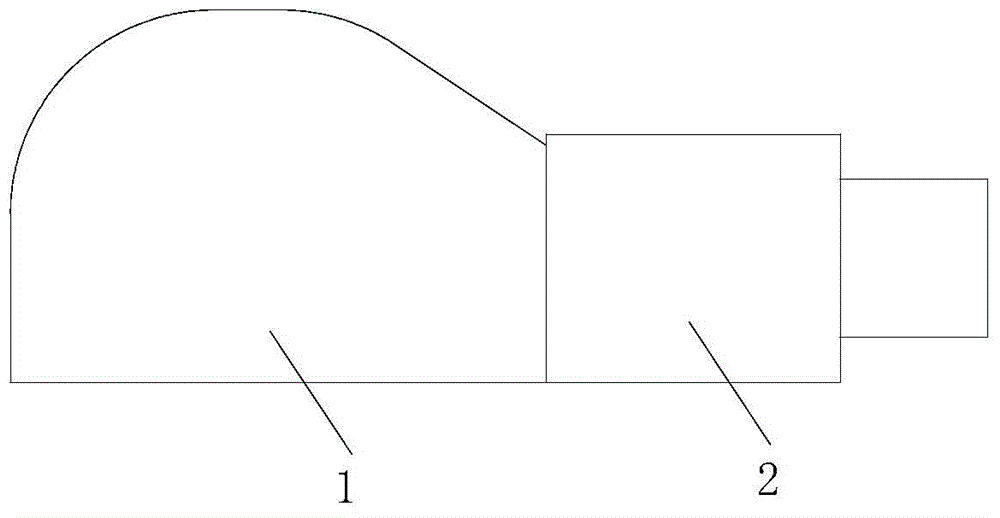

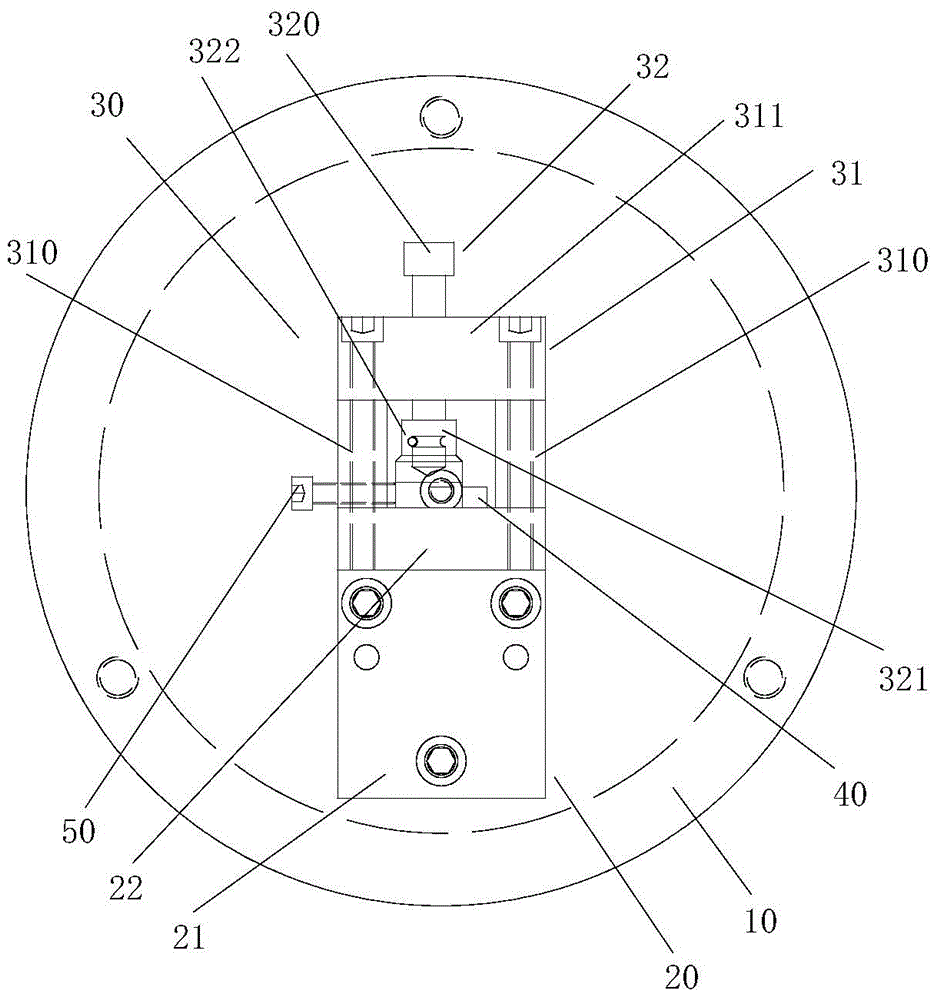

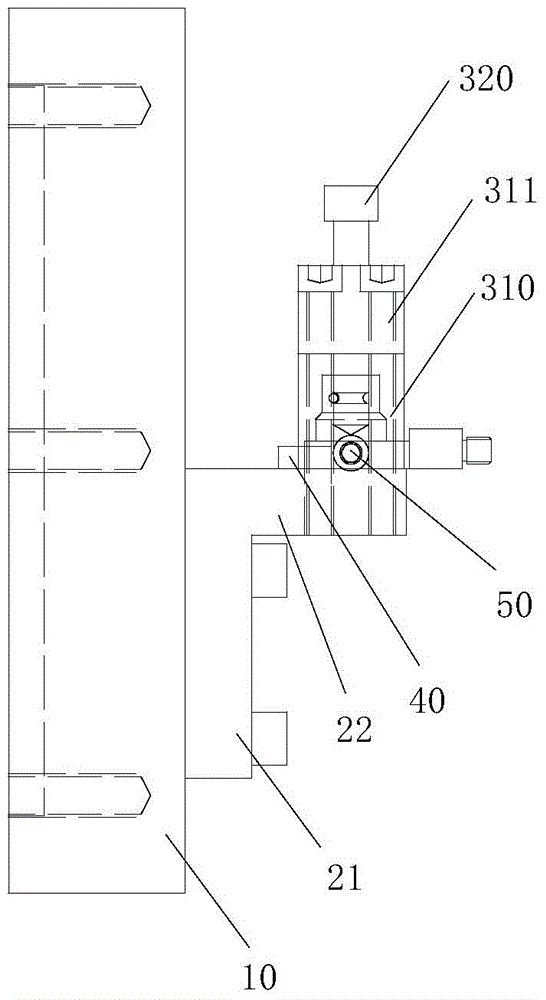

[0017] figure 1 It is a front view schematic diagram which shows the transmission hook of this invention. figure 2 It is a schematic front view showing the turning jig of the transmission hook blank of the present invention. image 3 It is a schematic side view showing the turning jig of the transmission hook blank of the present invention.

[0018] like figure 1 As shown, the transmission hook blank includes a hook forming portion 1 and a cylindrical hook handle 2 connected to the hook forming portion 1 .

[0019] like figure 2 , image 3 As shown, the turning fixture of the transmission hook blank has a chassis 10 , a support base 20 , a clamping member 30 , two positioning blocks 40 and a fastening screw 50 .

[0020] The chassis 10 is connected to the spindle of the lathe. The support base 20 is formed in an L shape, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com