A kind of service brake system and vehicle

A technology of driving brakes and brakes, which is applied in the field of vehicles, and can solve problems such as poor thermal degradation resistance and reliability, and large differences in braking torque between the left and right wheels of the rear axle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the service brake system and the vehicle provided by the embodiments of the present invention will be described below with reference to the accompanying drawings.

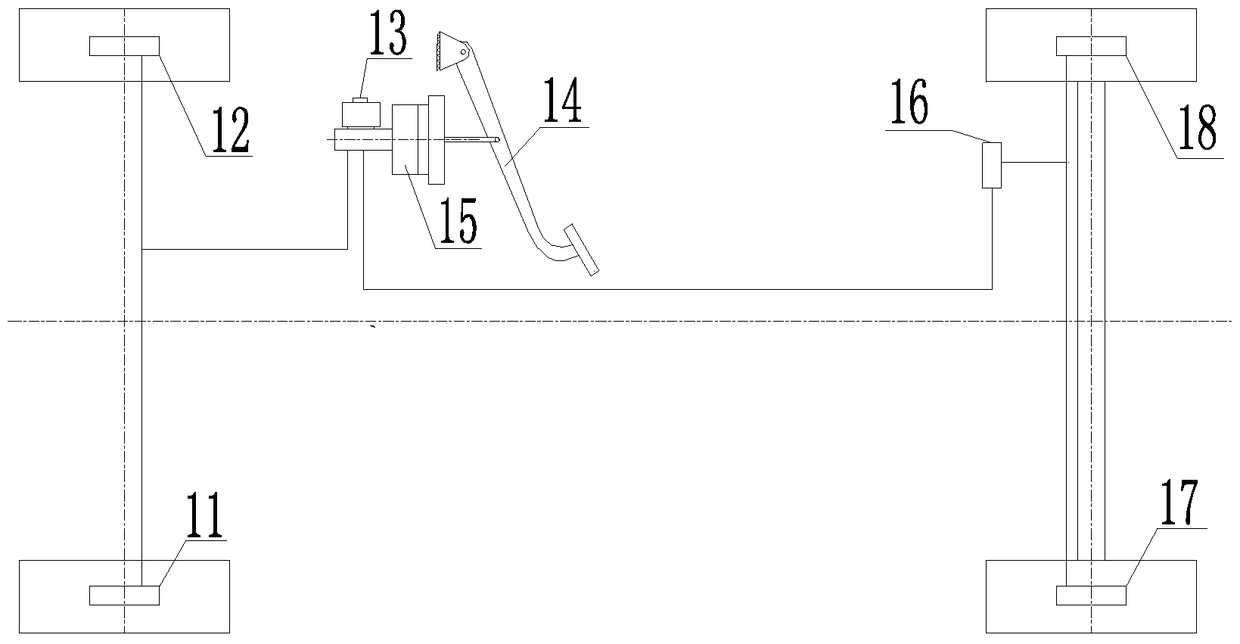

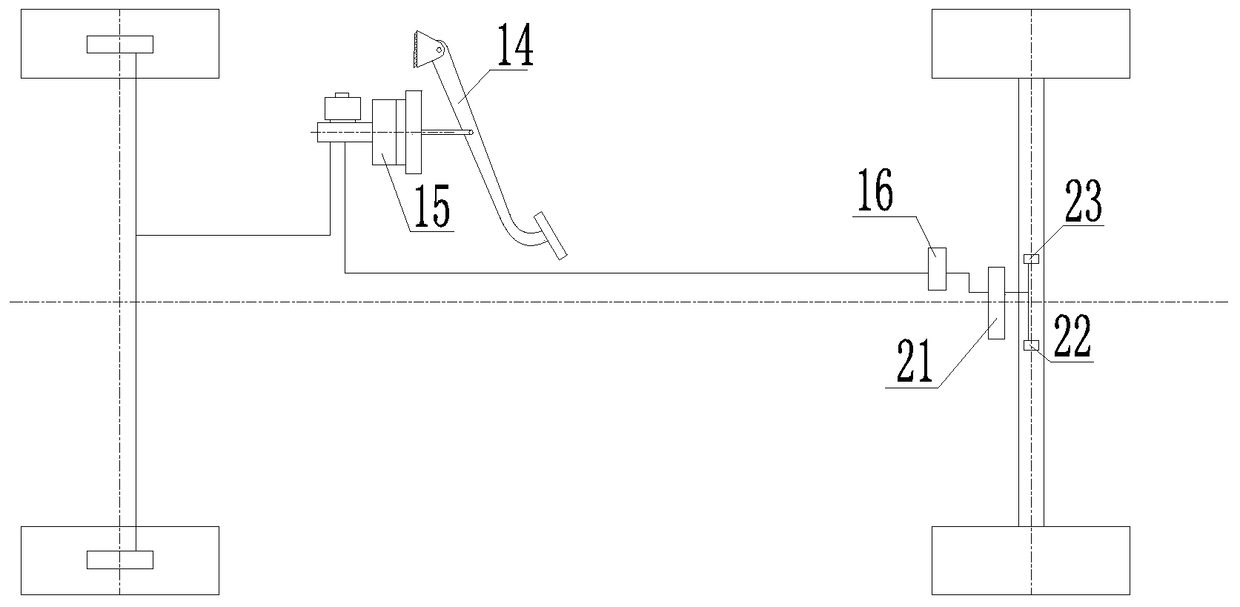

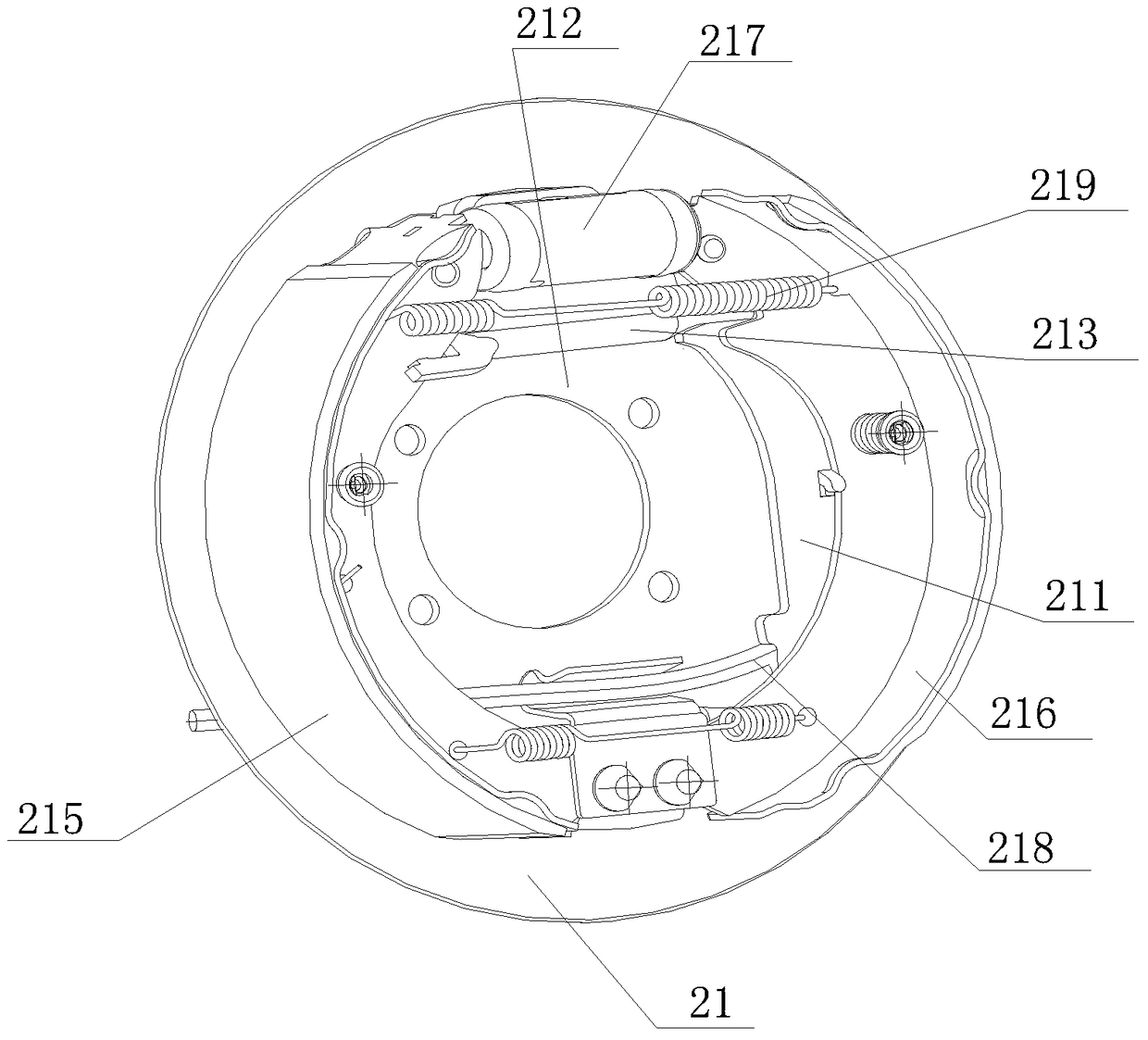

[0021] The embodiment of the present invention provides a service braking system, which includes: a brake pedal assembly 14, a front brake circuit and a rear brake circuit, and the brake pedal assembly 14 is connected to the front brake circuit and the rear brake circuit respectively. The circuit is connected, wherein: the brake pedal assembly 14, the structure of the front brake circuit can be referred to as figure 1 The structures of the brake pedal assembly 14 and the front brake circuit in the shown existing service brake system. Different from the prior art, in the service brake system provided by the present invention, the rear brake circuit includes: the second chamber of the master cylinder assembly 15, the central brake assembly 21, the left differential lock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com