Novel food boxing machine

A cartoning machine, food technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problem of inability to put food, achieve the effect of simple structure, avoid transmission structure, and achieve large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

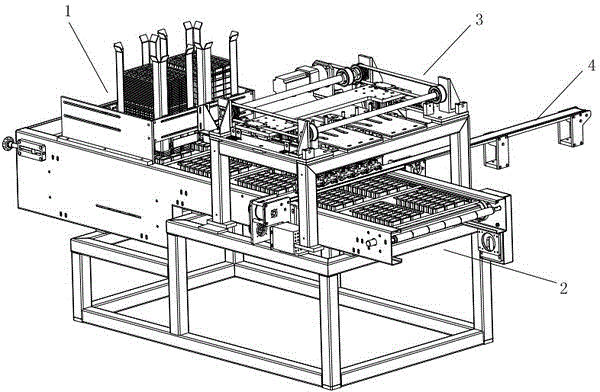

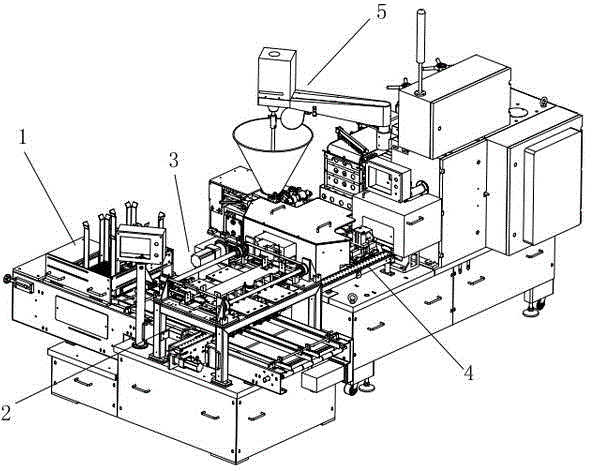

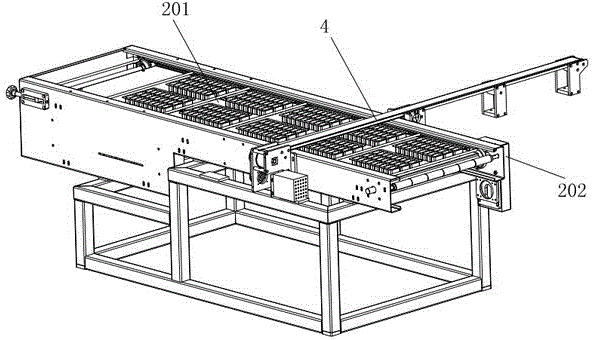

[0062] The new food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a push-in mechanism 3, and the box-down mechanism 1 and the pushing mechanism 3 are placed above the box-discharging conveying mechanism 2, and the box-discharging mechanism 1 is set At one end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and is positioned below the fixed mounting plate 320. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, The horizontal driving mechanism 304 is fixedly arranged on the fixed instal...

Embodiment 2

[0066] The new food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a push-in mechanism 3, and the box-down mechanism 1 and the pushing mechanism 3 are placed above the box-discharging conveying mechanism 2, and the box-discharging mechanism 1 is set At one end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and is positioned below the fixed mounting plate 320. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, The horizontal driving mechanism 304 is fixedly arranged on the fixed instal...

Embodiment 3

[0085] The new food cartoning machine includes a box-down mechanism 1, a box-discharging conveying mechanism 2 and a push-in mechanism 3, and the box-down mechanism 1 and the pushing mechanism 3 are placed above the box-discharging conveying mechanism 2, and the box-discharging mechanism 1 is set At one end of the push-in mechanism 3, one side of the push-in mechanism 3 is provided with a conveyor belt for transmitting the food to be discharged; it includes a mounting frame 301, and the mounting frame 301 includes a fixed mounting plate 320 and is positioned below the fixed mounting plate 320. A plurality of mechanical push pedals 302, the guide device 303 for adjusting the distance between adjacent mechanical push pedals 302 is installed on the mechanical push pedals 302, the mechanical push pedals 302 are connected with a horizontal drive mechanism 304 that drives them to realize horizontal movement, The horizontal driving mechanism 304 is fixedly arranged on the fixed instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com