Turnover mechanism of film laminating machine

A film laminating machine and flipping technology, which is applied in the direction of flipping objects, pile separation, thin material processing, etc., can solve the problems of high labor cost and low film lamination efficiency, and achieve the effects of low cost, improved film lamination efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

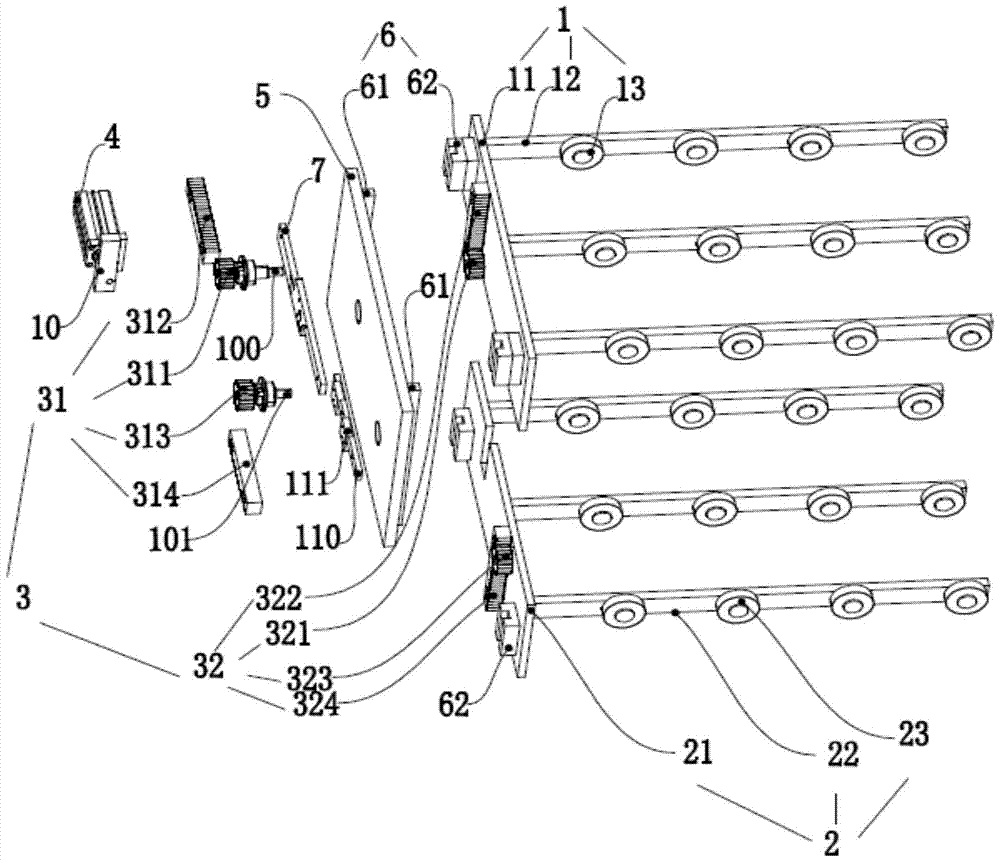

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

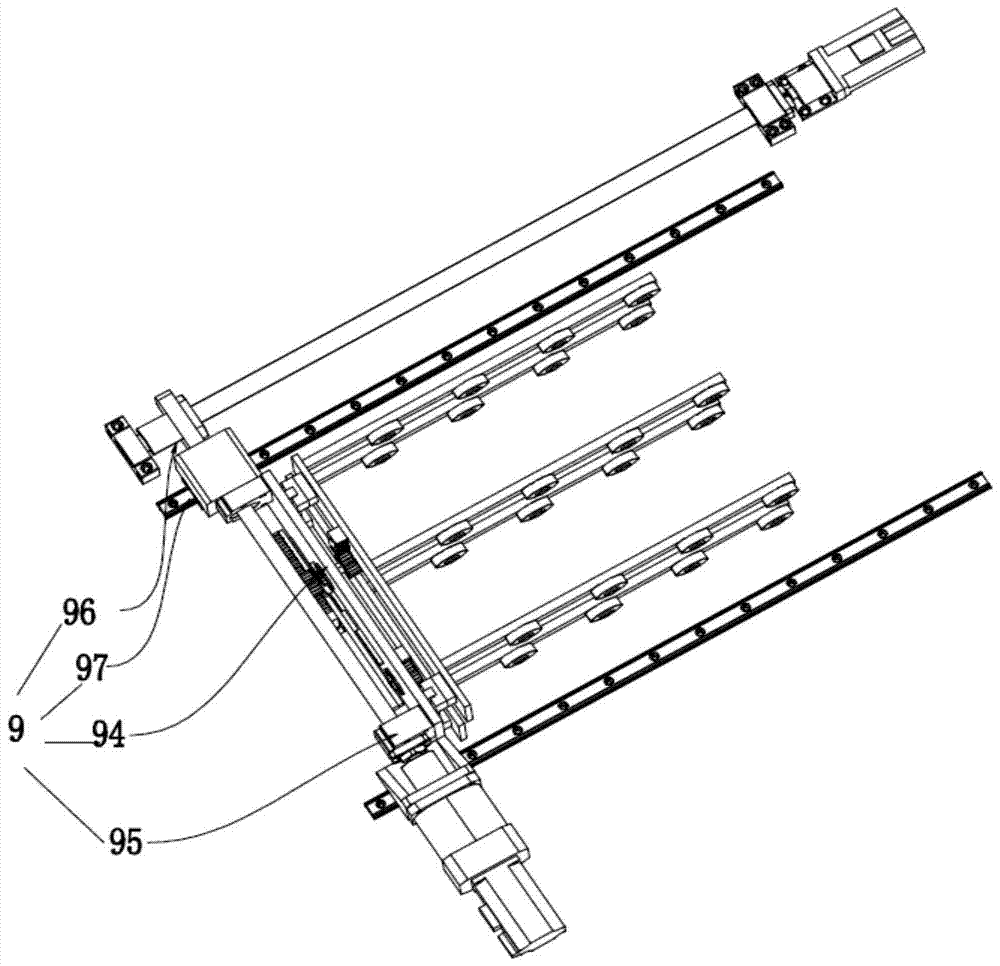

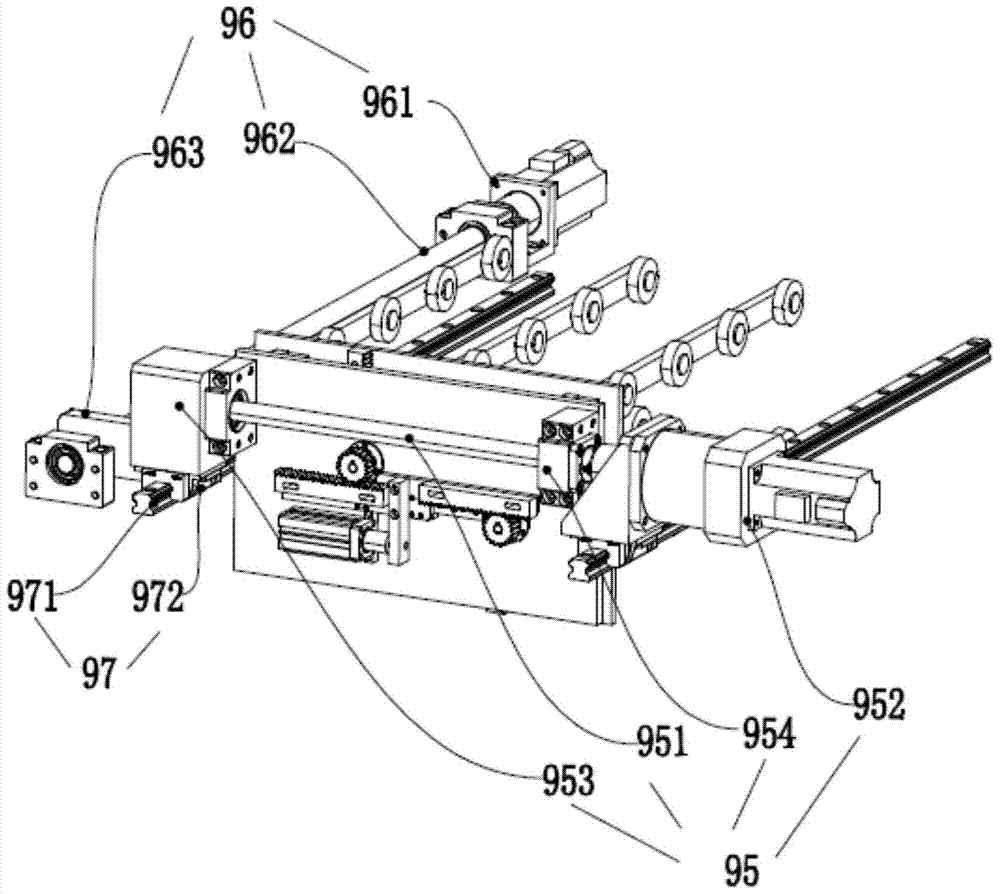

[0029] The turning mechanism of the film laminating machine is located in the middle of the double-sided film sticking device; it includes a clamping device 94, a matching rotating device 95, a turning guide rail 97 and a moving drive device 96, and the clamping device 94 clamps the workpiece. The clamping device 94 rotates under the drive of the matching rotating device 95, and the matching rotating device 95 reciprocates along the turning guide rail 97; At one end, the cooperating rotating device 95 drives the clamping device 94 to rotate from the horizontal direction to the vertical direction, and the moving driving device 96 drives the cooperating rotating device 95 to move to the first position of the turning guide rail 97. After the two ends, the cooperating rotating device 95 drives the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com