AFM probe array integrated with ultrasonic energy transducers

A technology of ultrasonic transducer and probe array, which is applied in scanning probe technology, scanning probe microscopy, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. Internal imaging and other problems, to achieve the effect of speeding up scanning imaging speed, solving slow speed, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

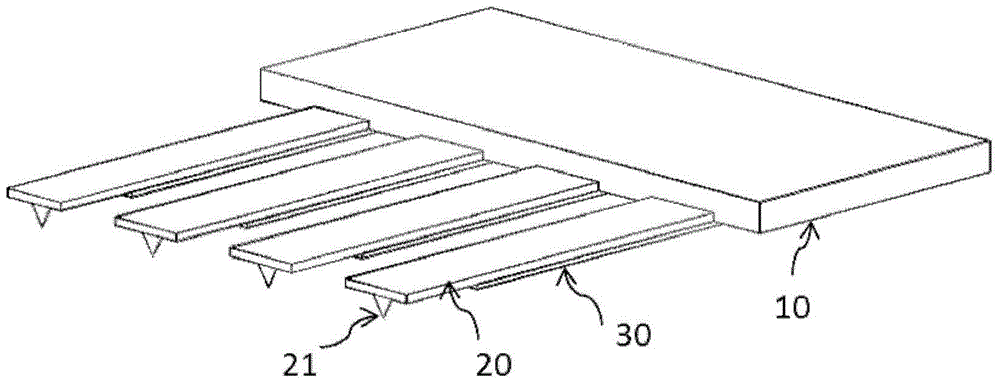

[0031] see again figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, wherein the ultrasonic transducer is a comb-shaped AFM probe array structure, including:

[0032] A base 10, the base 10 is rectangular;

[0033] A plurality of micro-cantilever beams 20, which are respectively connected to one side of the base 10, each micro-cantilever beam 20 is made with a needle tip 21 below the end;

[0034] A plurality of ultrasonic transducers 30, which are respectively fabricated on the back of a plurality of micro-cantilever beams 20 and or the back of the base 10;

[0035] Wherein a plurality of micro-cantilever beams 20 and a plurality of ultrasonic transducers 30 form a probe array.

Embodiment 2

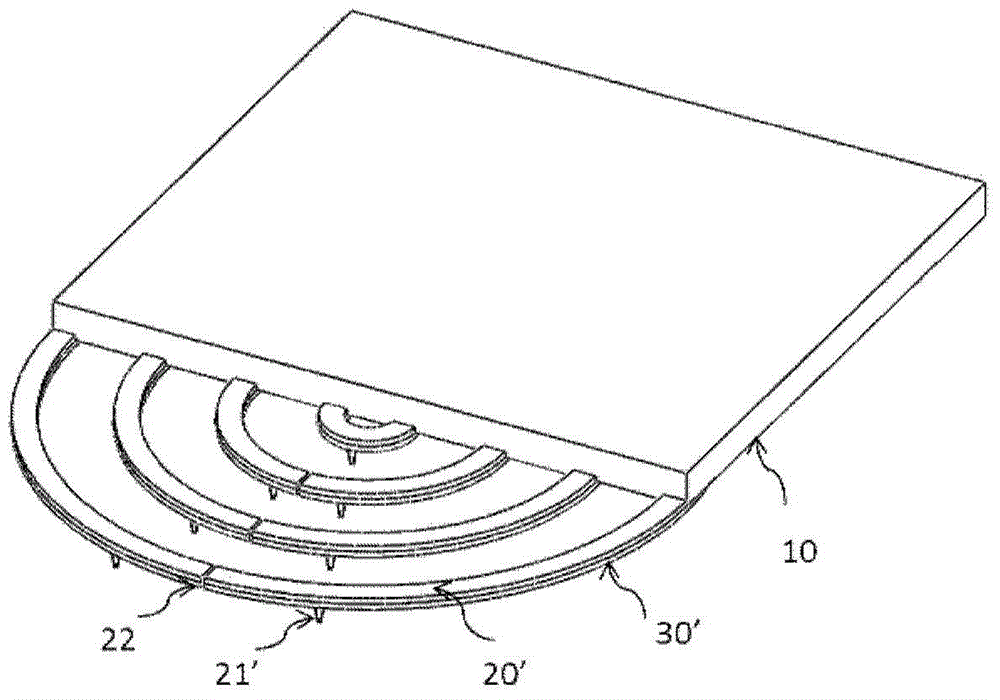

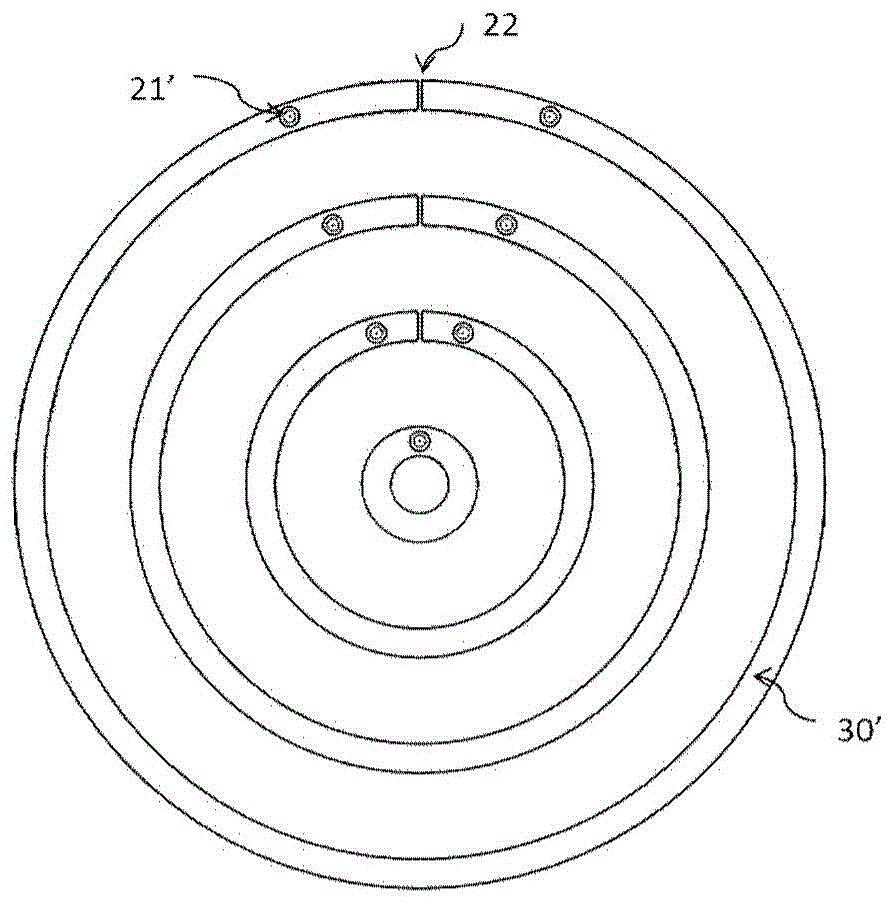

[0037] see again figure 2 and image 3 , is a structural schematic diagram of Embodiment 2 of the present invention, wherein the AFM probe array structure when the ultrasonic transducer is a ring type includes:

[0038] A base 10, the base 10 is rectangular;

[0039] A plurality of ring-shaped micro-cantilever beams 20' are respectively connected to one side of the base 10, and each ring-shaped micro-cantilever beam 20' is made with a needle point 21';

[0040] A plurality of ring-shaped ultrasonic transducers 30', which are respectively fabricated on the back of a plurality of ring-shaped micro-cantilever beams 20' and or the back of the base 10;

[0041] Wherein a plurality of annular micro-cantilever beams 20' and a plurality of annular ultrasonic transducers 30' form a probe array.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com