Electroplating drum unit

A technology for electroplating drums and drums, applied in the electrolysis process, electrolysis components and other directions, can solve problems such as labor costs, and achieve the effect of improving the level of automation, reducing labor costs, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

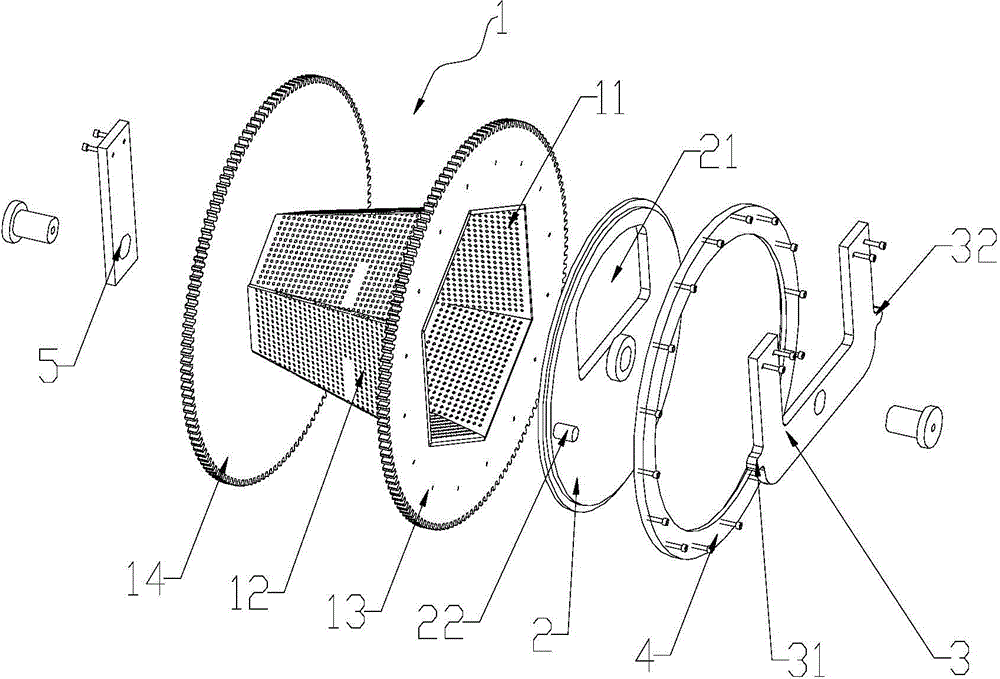

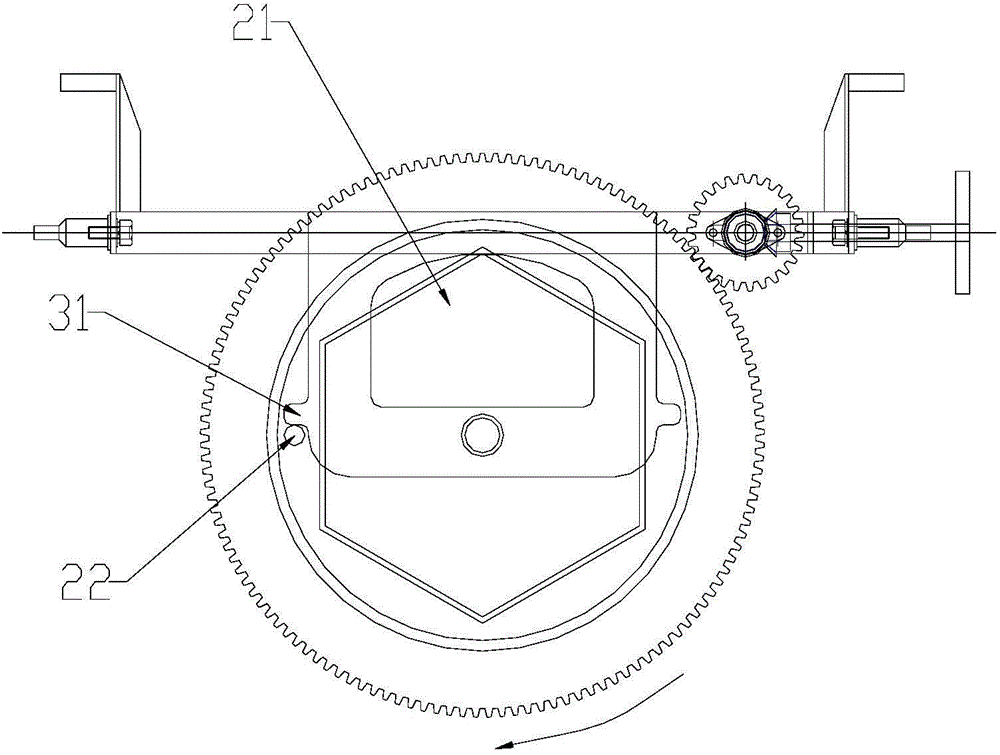

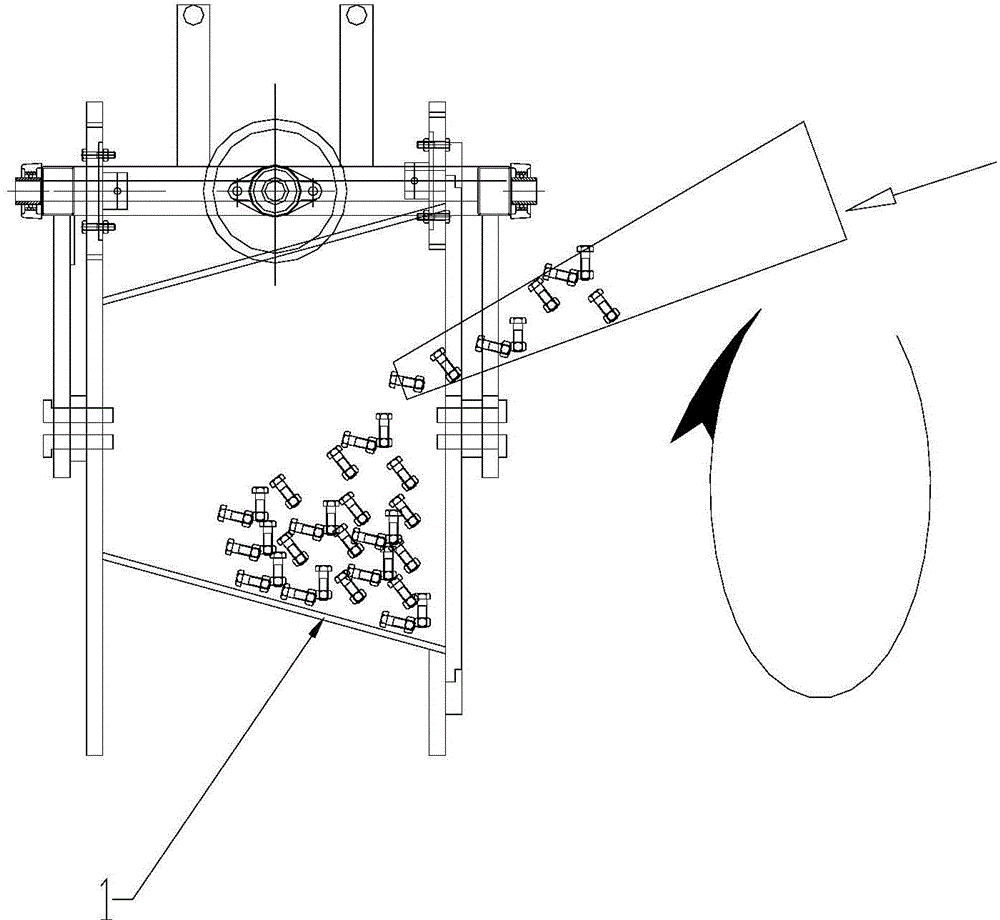

[0025] Such as Figure 1-6 As shown, the electroplating drum device of the present invention includes a hollow drum 1, a movable cover 2 that is in frictional contact with the front end of the drum 1 and can rotate with the drum 1 under the action of friction, and a stopper The front end of the drum 1 is provided with an over-center front opening 11; the movable cover 2 is provided with an inlet and outlet 21 and a positioning part 22; Stopper 32; the positioning part 22 can move between the first stopper 31 and the second stopper 32 with the rotation of the movable cover 2; the positioning part 22 moves to abut against the first stopper 31 When the material inlet and outlet 21 is facing the upper end of the front opening 11 of the drum 1;

[0026] In use, when the drum 1 rotates clockwise under the action of external force, the movable cover 2 rotate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap