Diesel particulate filter (DPF) carbon accumulation estimation method

A particle trap and carbon accumulation technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as unreliability, low calculation accuracy, difficulty in implementation, and poor estimation accuracy, so as to improve accuracy , improve calculation accuracy, and simplify the judgment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

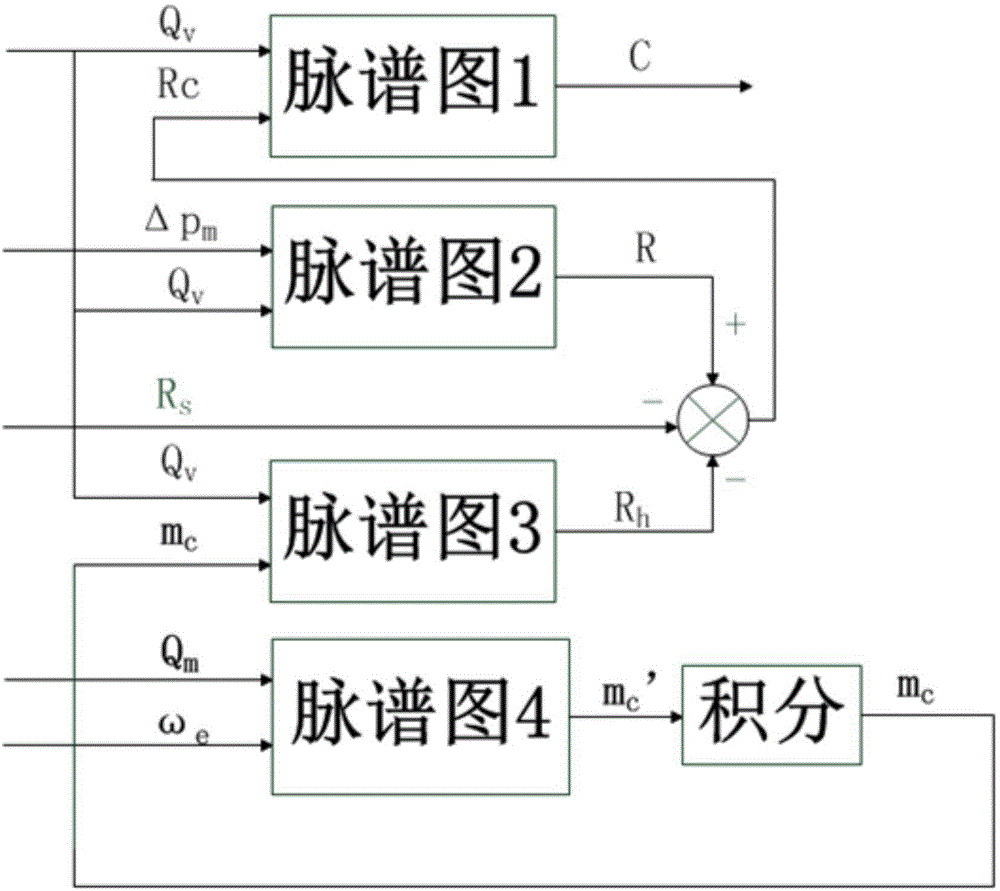

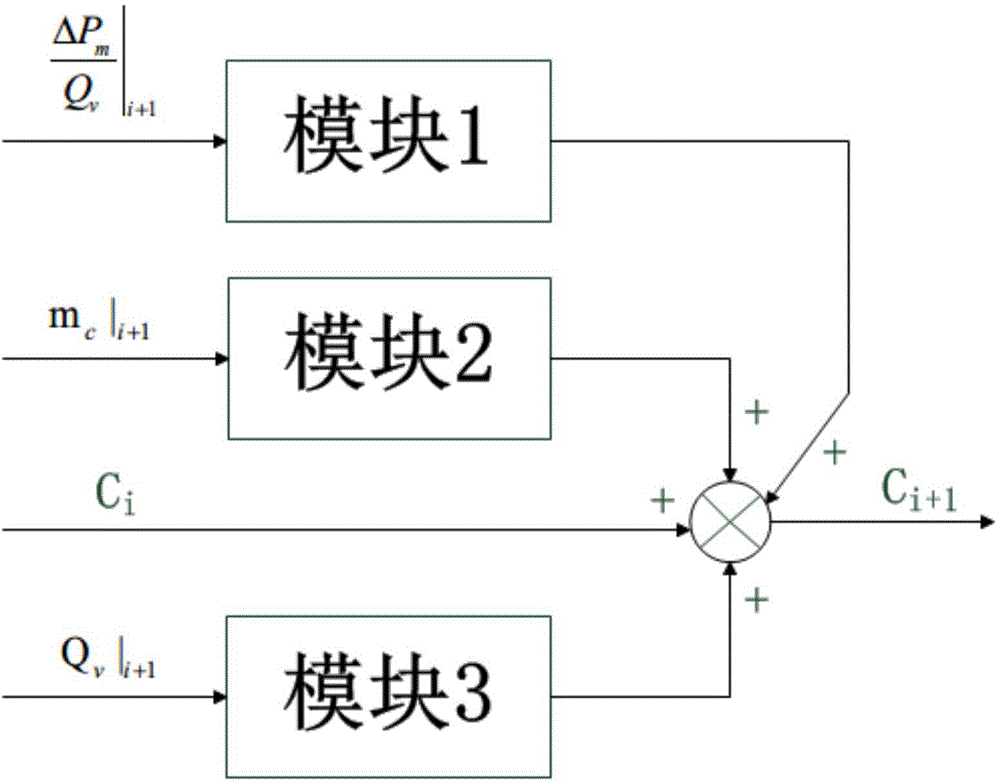

[0052] The present invention will be further described below in conjunction with the accompanying drawings. The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0053] The present invention proposes a new method for calculating the carbon accumulation of diesel particulate traps, which avoids the use of many correction coefficients with unclear physical meanings, improves the calculation accuracy of carbon accumulation, and simplifies the judgment process of carbon accumulation. Significantly improved the accuracy of judging the timing of DPF regeneration.

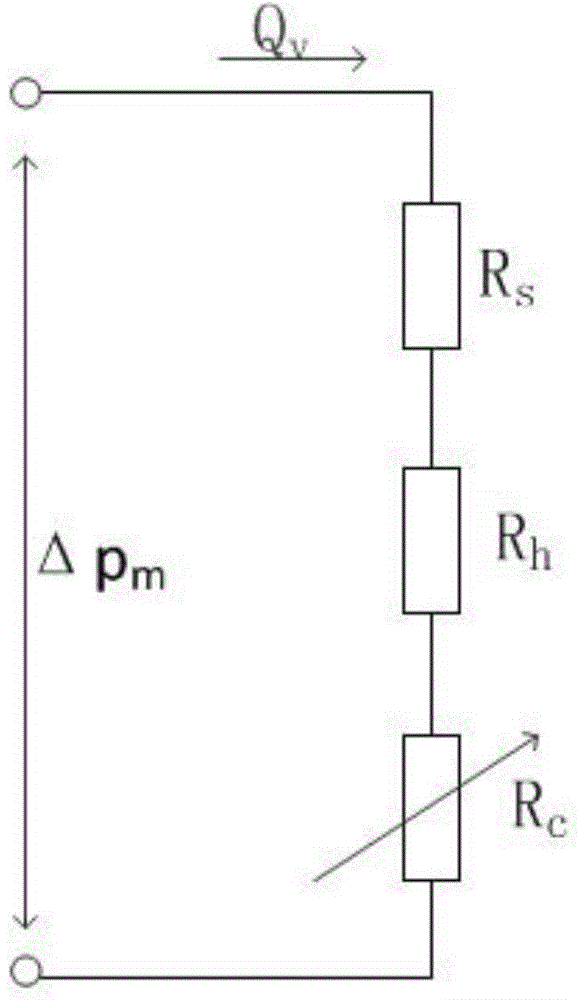

[0054] The total pressure difference before and after the DPF is measured by the pressure sensor;

[0055] According to the total pressure difference before and after the DPF and the exhaust gas volume flow rate, the total flow resistance of the DPF is obtained;

[0056] According to the mass of ash and the volume f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com