LED lamp heat dissipation structure

A heat dissipation structure, LED lamp technology, applied in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc. Service life and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

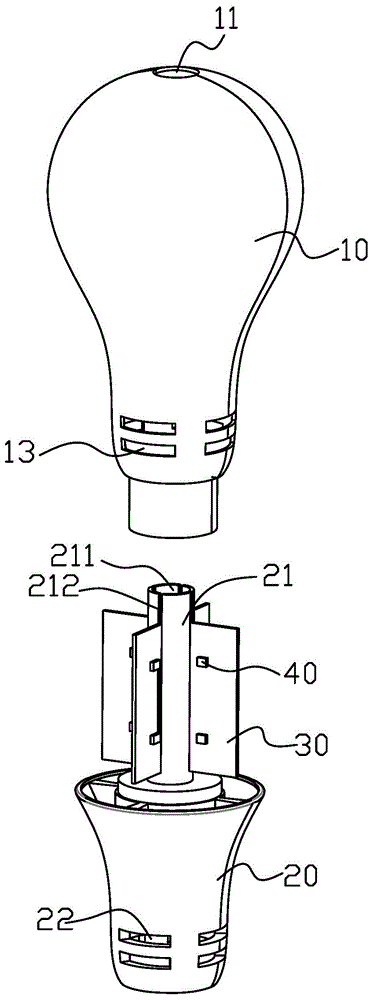

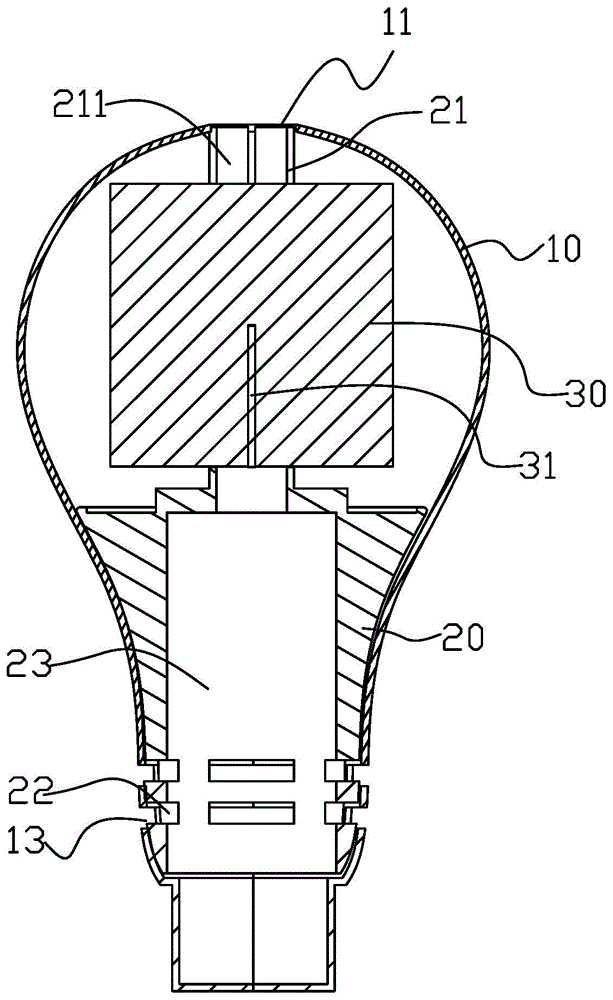

[0014] figure 1 It is a three-dimensional exploded view of the heat dissipation structure of the LED lamp according to the first embodiment of the present invention. The heat dissipation structure of the LED lamp includes a bulb shell 10, a lamp holder shell 20, and a substrate 30 thermally connected to the LED light source 40. The bulb shell 10 is covered by the A cavity is formed on the lamp housing 20 and the top of the lamp housing 20 to accommodate the substrate 30 .

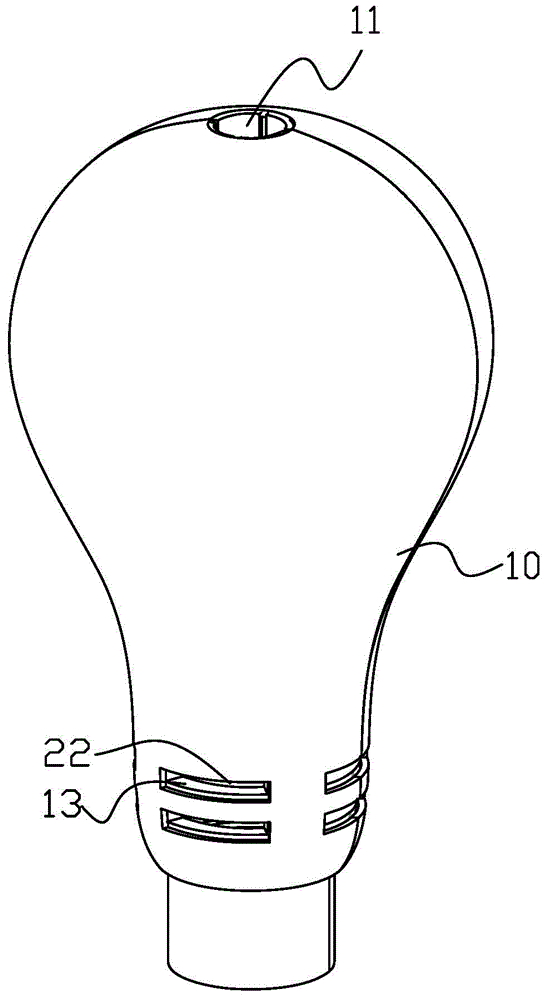

[0015] Please refer to figure 1 and figure 2 , the bulb shell 10 is provided with first air holes 11 , and these first air holes 11 are arranged on the top of the light bulb shell 10 . The bulb shell 10 is a hemispherical bulb shell structure, and the bulb shell 10 is formed by buckling two half shells.

[0016] Please refer to Figure 1 to Figure 3 , the top of the lamp housing 20 is provided with a ventilation column 21 , and the ventilation column 21 is integrally formed with the lamp housing 20 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap