High-speed railway sound barrier insertion loss prediction method of five-sound-source mode

A technology for insertion loss and high-speed railways, applied in noise absorption devices, special data processing applications, instruments, etc., can solve problems such as engineering design difficulties, limited scope of application, difficult noise source distribution characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

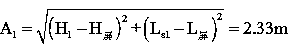

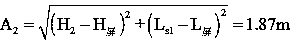

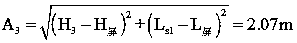

[0081] Village A proposed case: Village A is located near a high-speed railway, and it is a one-story building. The shortest distance from the center line of the outer rail of the line is 30m; The height of the upper edge of the outer side of the wing plate is the elevation of the rail top, and the lower edge of the outer side of the wing plate is 0.9m lower than the top of the railway track; the track surface is 8m above the ground, and the sensitive point is located 1.2m above the ground; it is planned to install a high sound barrier treatment 2.05m above the rail surface Noise, the horizontal distance between the inner side of the sound barrier and the center line of the outer line of the railway is 3.31m; the speed of the train passing through the section to be installed with the sound barrier is 300km / h; the theoretical noise reduction amount of the predicted sound barrier is the insertion loss of the sound barrier.

[0082] The specific calculation steps are as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com