NSGA-II-based three-dimensional printing multi-task optimal scheduling method

A technology of 3D printing and optimized scheduling, applied in the direction of additive processing, etc., can solve problems such as multi-task scheduling in 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

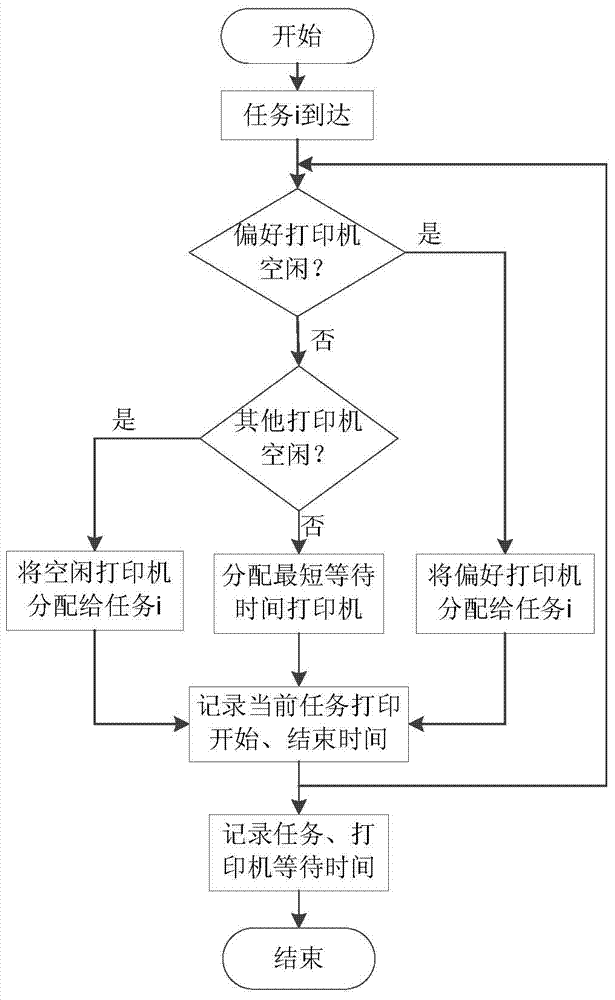

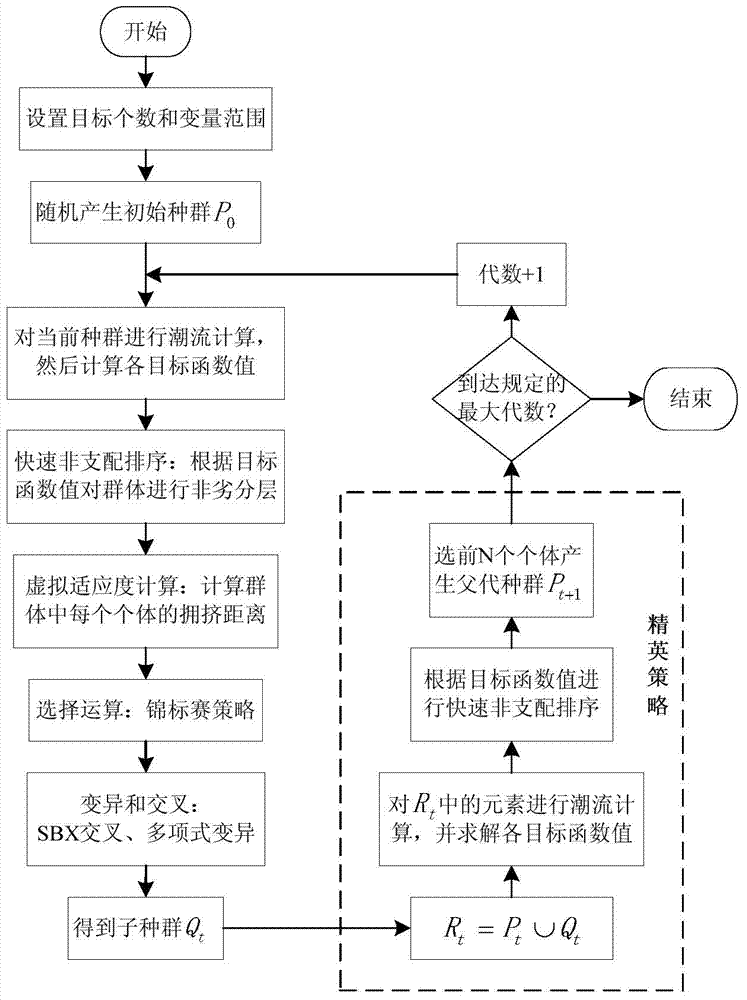

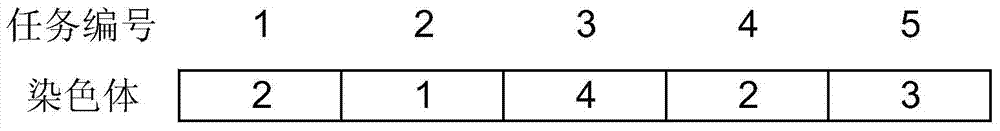

[0023] The present invention utilizes the NSGA-II multi-objective optimization method to realize multi-task optimization scheduling of 3D printing, and its realization steps are as follows:

[0024] 1. Generalization of 3D printing mode

[0025] 3D printing multi-task scheduling means that after 3D printing tasks are issued, they are assigned to corresponding idle printers according to certain printing requirements (printing accuracy, delivery time, printing cost, printing materials, etc.), which is a series of printing tasks issued and assigned to appropriate printers. printer, printing process. In terms of time, 3D printing multi-task scheduling can be divided into two stages: generation of scheduling scheme and execution of scheduling scheme. The first stage refers to generating an optimal or better scheduling plan by means of operational research and optimization. The premise of the normal operation of the plan is that the printing environment (task assignment and printer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com