Large-diameter marine air pipe head

An air pipe head, large-diameter technology, used in ship parts, ship construction, hull ventilation/heating/cooling, etc., can solve the problems of large volume, heavy weight, easy cracks, and the buoy cannot float quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

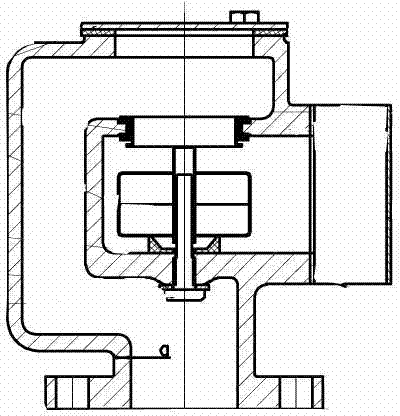

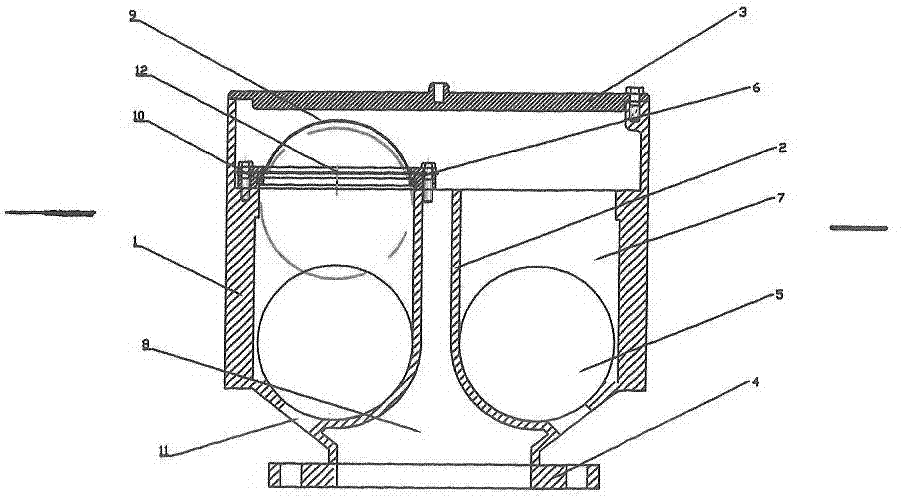

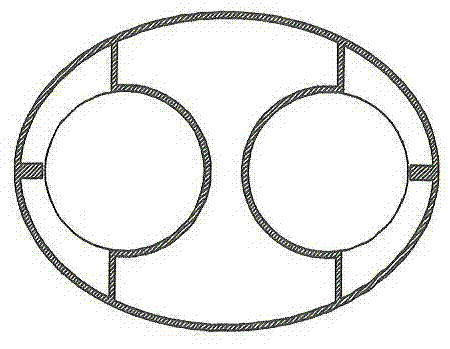

[0021] like figure 2 , image 3 Shown: a large-diameter marine air pipe head, including an outer shell 1, an inner shell 2, an end cover 3, a flange interface 4, a buoy 5, and a sealing cover 6. The top of the outer shell 1 is provided with an end cover 3, The end cover 3 is installed on the top of the outer shell 1 with screws, and the protective net 9 can be cleaned by opening the end cover 3; the flange interface 4 is installed at the bottom of the outer shell 1; two inner shells 2 are arranged at the left and right ends of the outer shell 1, The two inner casings 2 are all in the shape of barrels with upward openings, and sealing covers 6 are respectively provided above the inner casings 2, and the sealing covers 6 are tightly connected with the inner casings 2 to form a switching chamber 7, and the buoy 5 is The spherical shape is arranged in each switching chamber 7, and each sealing cover 6 has a circular hole 12 respectively. The diameter of the circular hole 12 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com