System for adjusting ethylene output

An ethylene production technology, applied in the system field of adjusting ethylene production, can solve the problems of high storage cost, harsh storage conditions, and low ethylene, and achieve the effects of reducing dependence, eliminating surplus, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

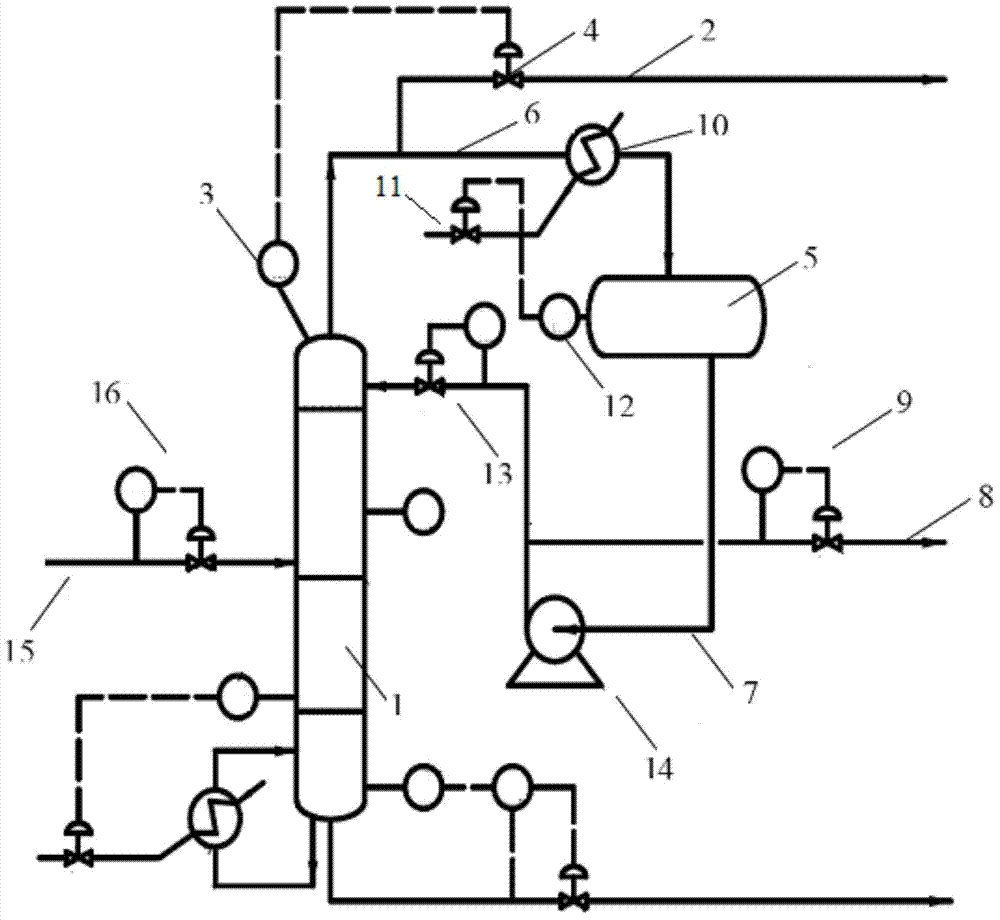

[0022] The present invention is described now in conjunction with accompanying drawing. Such as figure 1 Shown is a schematic structural diagram of a system for adjusting ethylene production according to the present invention, which includes a rectification tower 1 and a circulating ethylene pipeline 2 connected to the top of the rectification tower 1 .

[0023] More specifically, a pressure transmitter 3 is installed at the top of the rectification column 1, and a circulating ethylene pipeline regulating valve 4 is connected in series in the circulating ethylene pipeline 2, and the pressure transmitter 3 is electrically connected to the circulating ethylene pipeline regulating valve 4.

[0024] Continue to refer to figure 1 , In a preferred embodiment, the system of the present invention further includes a return tank 5 having a return inlet and a return outlet. For the reflux tank 5 , the reflux inlet communicates with the top of the rectification column 1 through the refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com