Triaxial receiving antenna and manufacturing method therefor

A receiving antenna and coil technology, applied in the field of communication, can solve the problems of low reliability, complex manufacturing process, and low production efficiency, and achieve the effect of high product reliability and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

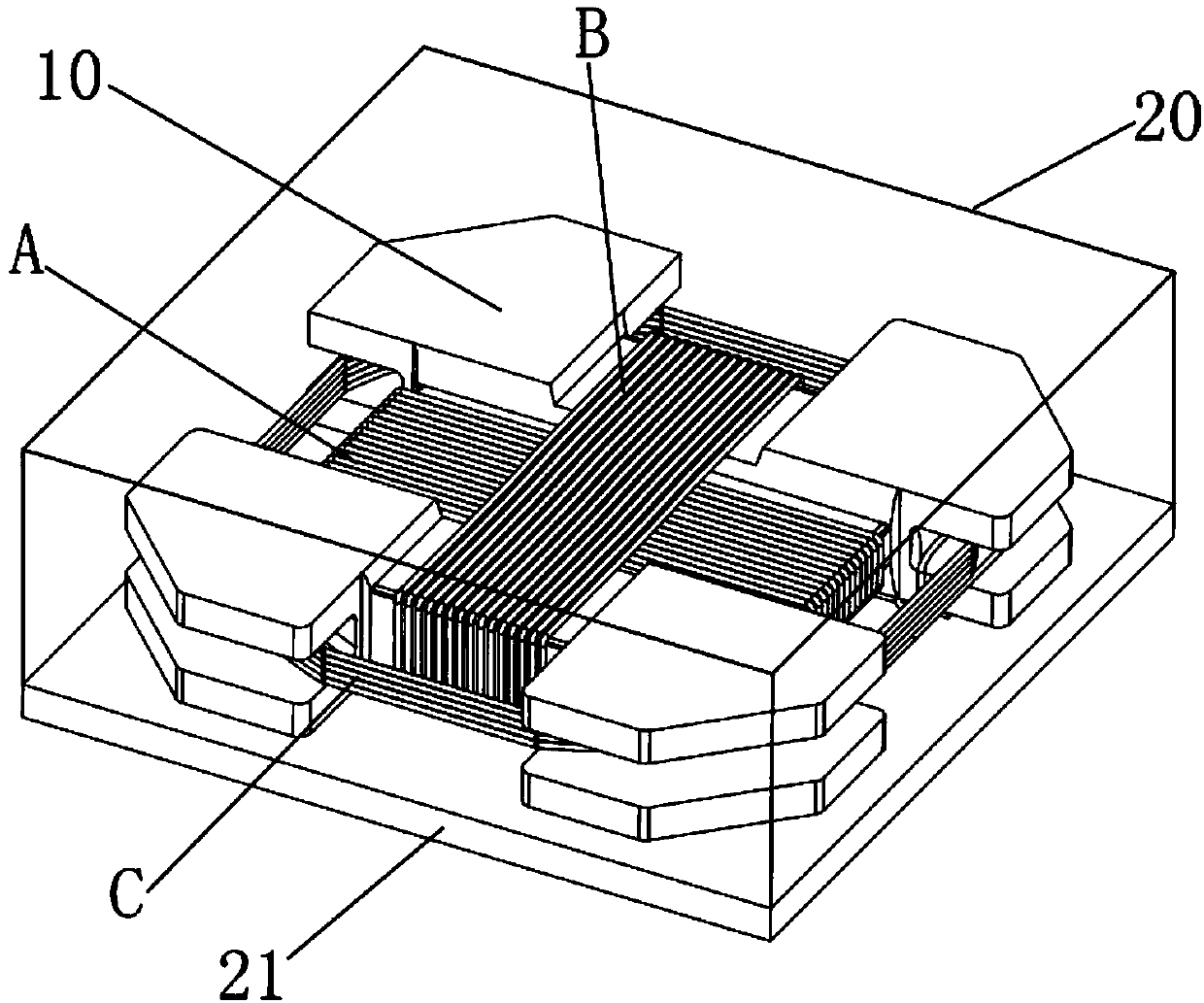

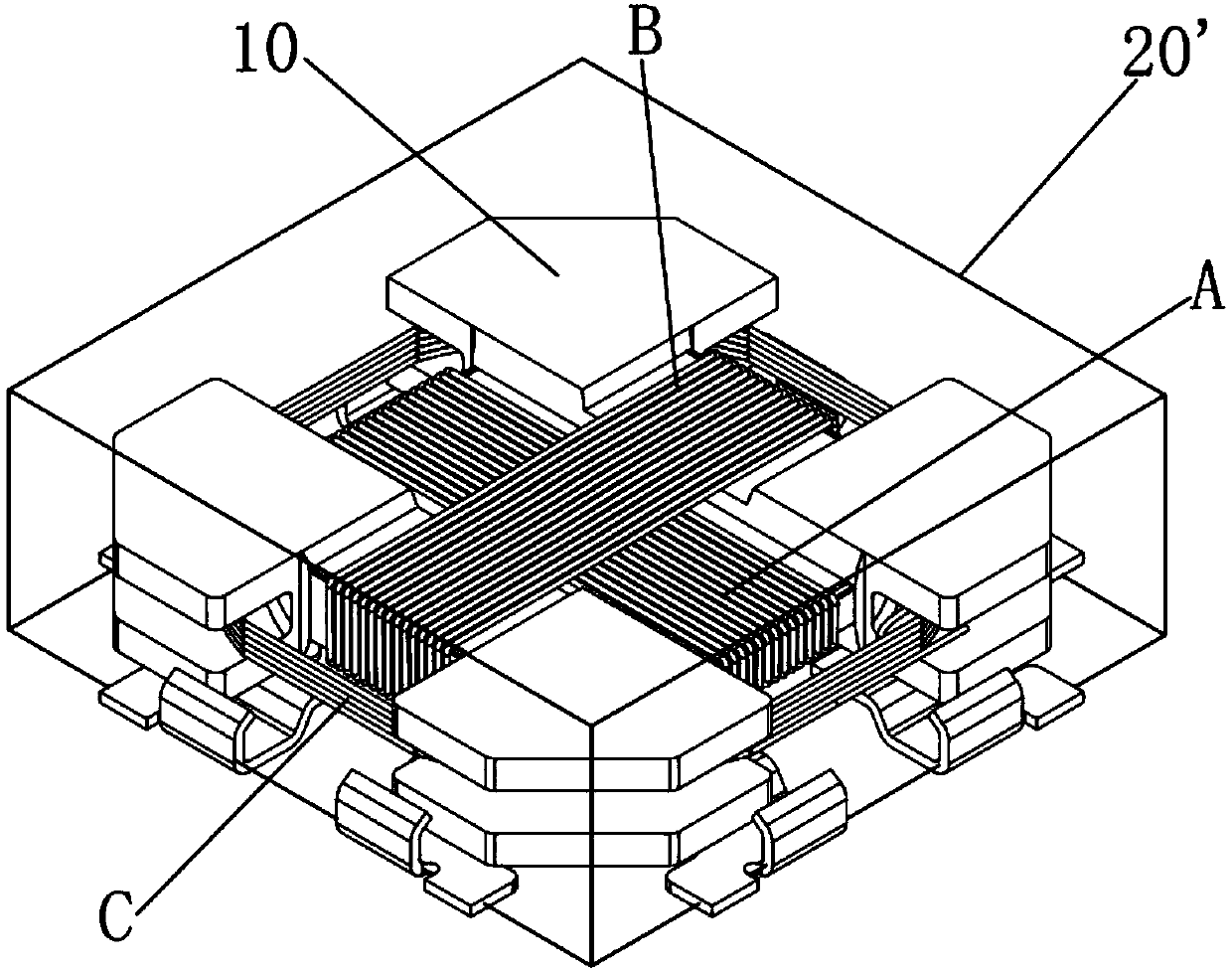

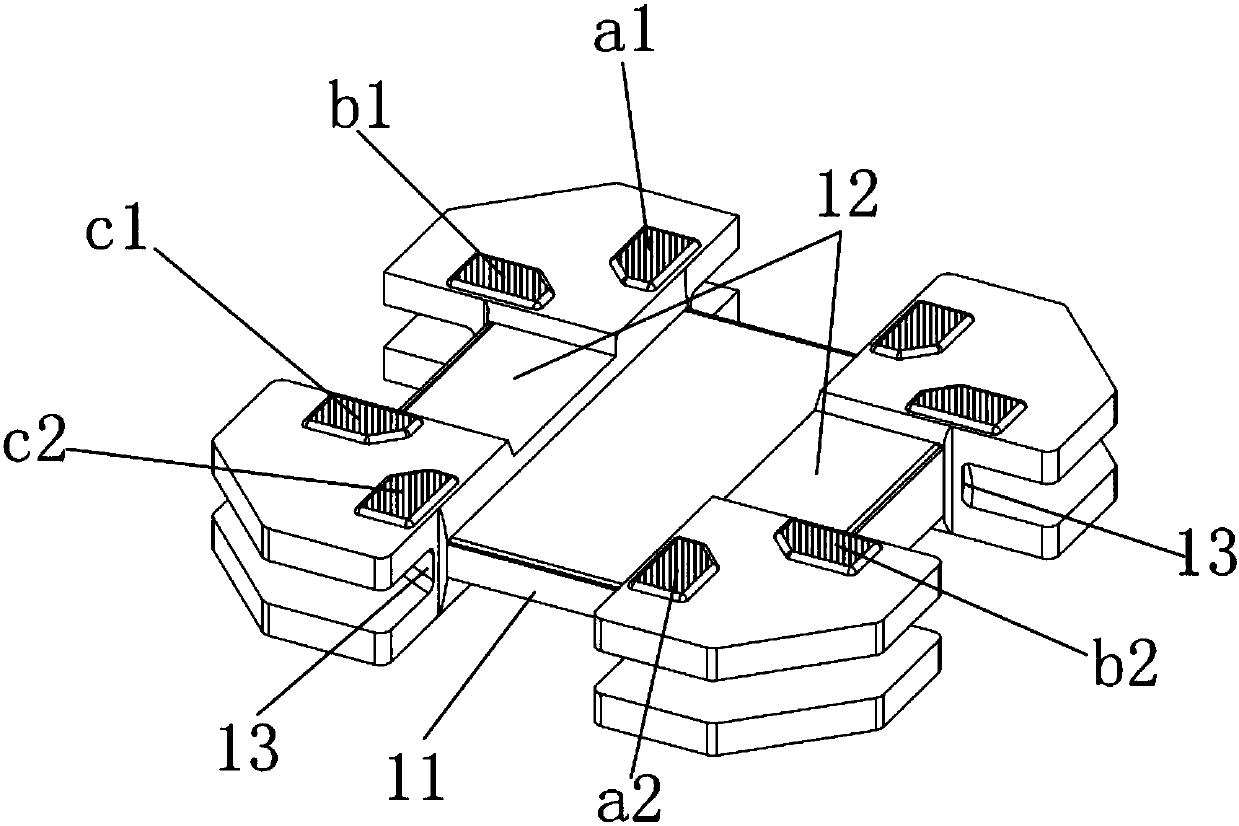

[0027] A specific embodiment of the present invention provides a three-axis receiving antenna, refer to figure 1 and figure 2 , the three-axis receiving antenna includes a magnetic core 10, three sets of coils A, B, and C wound on the magnetic core 10, and a package 20 (20'). The three groups of coils are wound on the three winding portions of the magnetic core 10 in a spatially orthogonal manner, and the wire ends of each group of coils are connected to corresponding electrodes disposed on the magnetic core. The packaging body is formed by packaging the magnetic core and its winding coils after the winding of the three sets of coils is completed, so that the magnetic core and coils are all located inside the packaging body. The bottom of the package has several conductive parts that conduct on both sides, the number of the conductive parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com