Combustion system with pre-combustion chamber combustors arranged on two side walls of boiler and combustion method

A technology of combustion system and pre-combustion chamber, which is applied in the direction of combustion method, combustion using lump fuel and liquid fuel, combustion using lump fuel and gaseous fuel, etc., and can solve the problems of poor combustion stability under low load and high emission , to achieve the effect of increasing the load range and improving the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

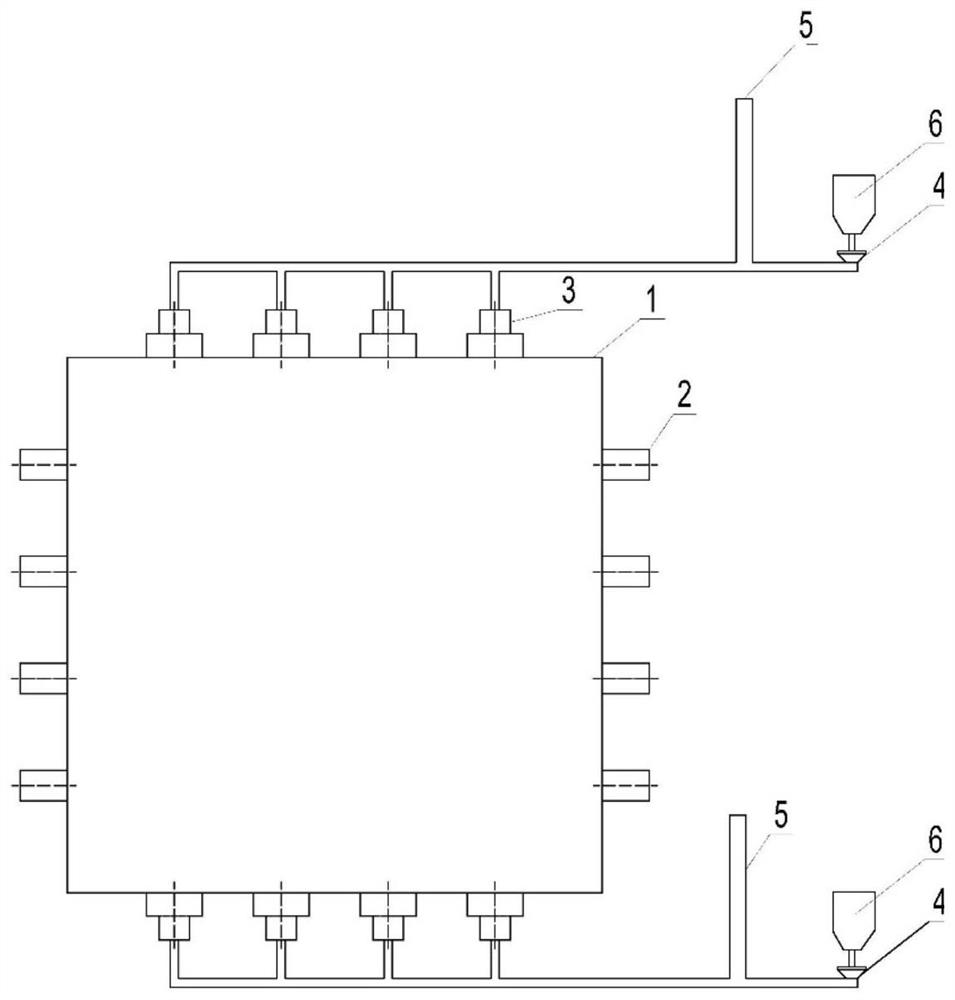

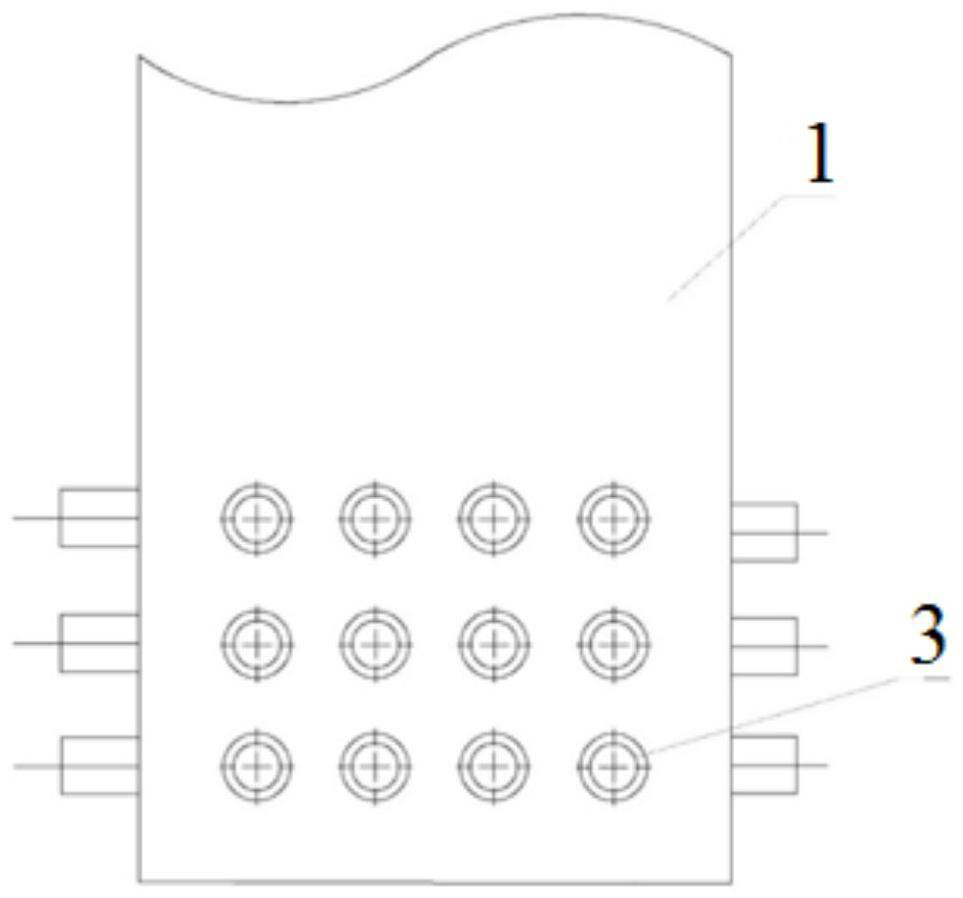

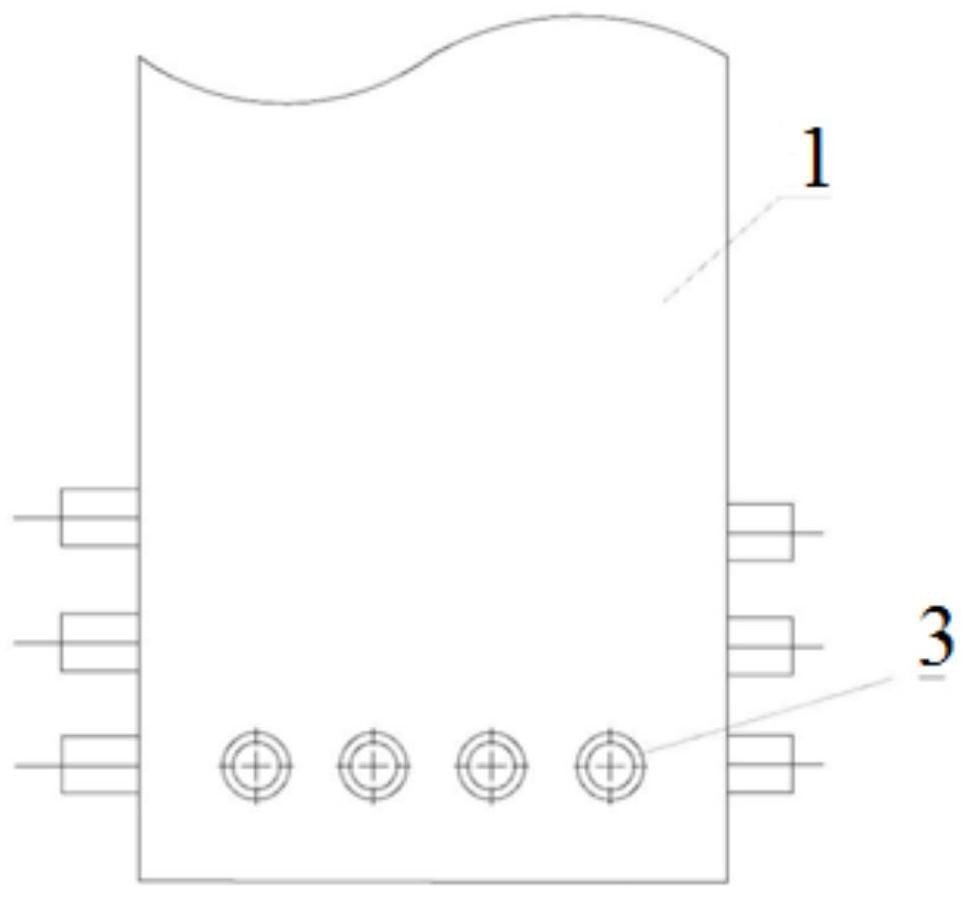

[0026] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, the combustion system with pre-chamber burners on both sides of the boiler described in this embodiment includes a furnace 1, two sets of main burner mechanisms and two sets of pre-chamber burner mechanisms, and two sets of main burners The mechanism is relatively arranged on the two side walls of the furnace 1, and two sets of pre-chamber burner mechanisms are relatively arranged on the other two walls of the furnace 1.

[0027] The boiler is a power station boiler, specifically an offset coal-fired boiler.

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, each group of pre-chamber burner mechanisms in this embodiment includes a powder feeder 4, a recirculation flue gas pipe 5, a powder storage bin 6 and a plurality of pre-chamber burners 3, and a plurality of pre-chamber burners 3 are The cloth is arranged at the bottom of the side wall of the furnace 1, and the powder outlet end of the powder storage bin 6 is connected with the powder inlet end of the powder feeder 4, and the powder outlet end of the powder feeder 4 is respectively connected with multiple pre-chamber burners 3 through powder feeding pipes , The powder feeding pipe is provided with a recirculation flue gas pipe 5, and the recirculation flue gas pipe 5 is provided with a control valve. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0029] The pre-combustion chamber burner 3 is separately connected with the ...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination Figure 1 to Figure 5 Describe this embodiment, a plurality of pre-chamber burners 3 in each group of pre-chamber burner mechanisms in this embodiment are evenly arranged in n layers, where n is a positive integer, and n layers of pre-chamber burners 3 are arranged from bottom to top They are arranged layer by layer on the side wall of the furnace 1, wherein the lowermost pre-combustion chamber burner 3 is arranged at the bottom of the side wall. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com